download/files/LCQ Deca_Duo Hardware Troubleshooting_8601.pdf

download/files/LCQ Deca_Duo Hardware Troubleshooting_8601.pdf

download/files/LCQ Deca_Duo Hardware Troubleshooting_8601.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>LCQ</strong> <strong>Deca</strong>/<strong>Duo</strong> <strong>Hardware</strong><br />

<strong>Troubleshooting</strong><br />

Ed Gonzalez<br />

Product Support

Presentation Topics<br />

◗ Overview of the <strong>LCQ</strong> Ion Optic System<br />

◗ Tour of the <strong>LCQ</strong> Ion Optic System<br />

– Making Ions<br />

– Transferring Ions<br />

– Filtering Ions (Quadrupole Ion Trap)<br />

– Detecting Ions<br />

◗ <strong>LCQ</strong> Maintenance<br />

◗ <strong>LCQ</strong> Diagnostic Overview<br />

◗ Front Panel LEDs Indications

Mass Spectrometer<br />

Simplified Schematic<br />

Sample<br />

In<br />

Make<br />

Ions<br />

Transfer<br />

Ions<br />

Filter<br />

Ions<br />

Ion Optics System<br />

Detect<br />

Ions<br />

Data<br />

Out

200,000<br />

15,000<br />

1,000<br />

Molecular<br />

Weight<br />

Choice in Making Ions<br />

GC<br />

Non Polar<br />

Polarity vs. Molecular Weight<br />

APCI<br />

PBI<br />

ESI<br />

TSP<br />

FAB<br />

Polar

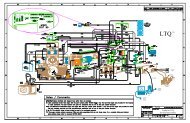

Simplified <strong>LCQ</strong> Schematic<br />

Sheath Liquid<br />

Auxiliary Gas<br />

Sheath Gas<br />

ESI Needle Assembly<br />

Heated Capillary<br />

Tube Lens Octapole Endcap<br />

Mechanical<br />

Pump<br />

Skimmer<br />

APCI Probe<br />

Assembly<br />

Turbo<br />

Pump<br />

Transfer Ions<br />

Turbo<br />

Pump<br />

Ring<br />

Electrode<br />

Electron<br />

Multiplier<br />

+15 kV<br />

Conversion<br />

Dynode<br />

Make Ions Desolvate Ions<br />

Filter Ions<br />

Detect<br />

Ions

<strong>LCQ</strong> Probes used in Making Ions<br />

◗ API-1 / ESI Probe (<strong>LCQ</strong> Classic)<br />

◗ API-2 / ESI Probe (<strong>LCQ</strong> <strong>Deca</strong> / <strong>LCQ</strong> <strong>Duo</strong>)<br />

◗ API-2 / Off Axis ESI Probe (Classic/<strong>Deca</strong>/<strong>Duo</strong>)<br />

◗ APCI Probe (Same for API-1 and API-2)

ESI Ionization Process<br />

ESI Ionization Process<br />

Simplified Schematic

±5kV ±5kV<br />

ESI Spray Cross Section<br />

Nozzle<br />

Gas Sheath<br />

Needle<br />

Liquid Sheath<br />

Ion Plume

Aerosol Formation<br />

Relative velocity between the sheath gas flow and the liquid flow<br />

causes a shearing effect on the emanating large droplet, and<br />

results in rapid droplet size reduction (spray)<br />

Sheath Gas<br />

Sample Tube<br />

Field lines<br />

Applied high voltage activates the<br />

coulombic explosion process<br />

Heated<br />

Capillary

API-1 API 1 / ESI Probe Assembly<br />

(<strong>LCQ</strong> Classic)

Cal Mix Tune Parameters<br />

API-1 on <strong>LCQ</strong> Classic<br />

◗ Infusion Flow Rate (µL/min.): 3-5<br />

◗ Spray Voltage (kV): 4-6<br />

◗ Spray Current (µA): 0.1-0.75<br />

◗ Sheath Gas Flow Rate (arb): 30-60<br />

◗ Aux. Gas Flow Rate (arb): 0<br />

◗ Capillary Temperature: 200-250°C<br />

◗ Probe Position : Pulled all the way back

<strong>LCQ</strong> <strong>Deca</strong> Tune Plus Window<br />

<strong>LCQ</strong> <strong>Deca</strong> Tune Plus Window<br />

ESI Source dialog and Status Panel

<strong>Troubleshooting</strong> the API1 Probe<br />

◗ Spray Current too high: High Voltage (HV) shorting effects:<br />

Leaks within ESI Probe<br />

Problematic mixture of solvents/sample/etc.<br />

◗ Erratic Spray Voltage: Shorted HV cable<br />

Spay current at maximum<br />

Bad HV supply<br />

◗ Erratic spray: Sample tube<br />

ESI needle<br />

Sheath gas flow<br />

◗ Contamination: Wipe spray shield around heated capillary<br />

Wipe out ESI probe flange<br />

Flush the ESI probe<br />

Clean ESI probe interior parts<br />

◗ Overall solution for 90% of source related Problems:<br />

� good maintenance<br />

(especially with the sample tube)<br />

� use of divert valve

API-1 API 1 / ESI Probe Cross Section

Sample Tube Elongation<br />

ESI Needle<br />

Sheath Liquid<br />

ESI Needle<br />

ESI Needle<br />

ESI Needle<br />

ESI Needle<br />

Polyimide<br />

Polyimide<br />

Sheath Liquid<br />

Sheath Liquid<br />

ESI Needle<br />

ESI Needle<br />

ESI Needle<br />

Polyimide<br />

Polyimide<br />

Sheath Liquid<br />

Fused Silica<br />

Fused Silica<br />

Fused Silica<br />

Fused Silica<br />

Sample<br />

Sample<br />

Elongation of polyimide<br />

occurs when specific<br />

solvents are adsorbed into<br />

the sample tube.<br />

The sample tube must be cut<br />

to ensure good spray.<br />

The sample tube must be cut<br />

square to ensure good spray.<br />

Best results can be achieved<br />

by making the sample tube<br />

flush with the ESI Needle.

Sample Tube Elongation Resolution<br />

ESI Needle<br />

Sheath Liquid<br />

ESI Needle<br />

Polyimide<br />

ESI Needle<br />

Polyimide<br />

Sheath Liquid<br />

ESI Needle<br />

ESI Needle<br />

Sheath Liquid<br />

ESI Needle<br />

Polyimide<br />

Polyimide<br />

Sheath Liquid<br />

ESI Needle<br />

Fused Silica<br />

Fused Silica<br />

Fused Silica<br />

Fused Silica<br />

Sample<br />

Sample<br />

The polyimide can be flamed<br />

to avoid elongation; however,<br />

make sure the end of the<br />

fused silica is cut square.<br />

Again, make sure the end of<br />

the fused silica is cut square.<br />

In this case, the fused silica<br />

is cut on an angle. This will<br />

produce poor spray.

Divert Valve Configuration<br />

TRANSFER LINE FROM<br />

DIVERT/INJECT VALVE<br />

TRANSFER LINE<br />

FROM LC PUMP<br />

SYRINGE<br />

PORT<br />

WASTE<br />

LINE<br />

3<br />

Front Panel Injections<br />

L oa d<br />

Detect or<br />

4<br />

2<br />

5<br />

DIVERT/<br />

INJECT<br />

VALVE<br />

6<br />

I nj ect<br />

Waste<br />

1<br />

TRANSFER LINE<br />

FITTING<br />

SAMPLE<br />

LOOP<br />

A U X I L I A R Y<br />

G A S<br />

S H E A T H<br />

G A S<br />

S A M P L E<br />

S H E A T H<br />

L I Q U I D<br />

H I G H<br />

V O LT A G E<br />

ESI SOURCE<br />

GROUNDED<br />

FITTING<br />

HOLDER<br />

SAMPLE TUBE

Divert Valve Configuration<br />

TRANSFER LINE FROM<br />

DIVERT/INJECT VALVE<br />

TRANSFER LINE<br />

FROM LC PUMP<br />

FROM LC<br />

PUMP<br />

TO ION<br />

SOURCE<br />

Normal Applications<br />

Load<br />

Detector<br />

3<br />

WASTE<br />

LINE<br />

3<br />

4<br />

2<br />

5<br />

6<br />

DIVERT/<br />

INJECT<br />

VALVE<br />

4<br />

2<br />

5<br />

TRANSFER LINE<br />

FITTING<br />

Inject<br />

Waste<br />

1<br />

6<br />

1<br />

SHEATH<br />

GAS<br />

AUXILIARY SAMPLE<br />

GAS<br />

SHEATH<br />

LIQUID<br />

GROUNDED<br />

FITTING<br />

HOLDER SAMPLE TUBE<br />

HIGH<br />

VOLTAGE<br />

ESI SOURCE<br />

FROM LC<br />

PUMP<br />

TO ION<br />

SOURCE<br />

3<br />

6<br />

WASTE 4<br />

WASTE<br />

TO MS TO WASTE<br />

2<br />

5<br />

1

Xcalibur Instrument Setup<br />

Divert Valve Dialog

API-2 API 2 / ESI Probe Assembly<br />

(<strong>LCQ</strong> <strong>Deca</strong> / <strong>LCQ</strong> <strong>Duo</strong>)

API-2 / ESI Probe Positions<br />

4 3 2 1<br />

Probe<br />

Positions

LC Flow Rate<br />

Infusion or LC at flow rates of<br />

API-2 API 2 / ESI Probe<br />

Exploded Pictorial

Cal Mix Tune Parameters<br />

API-2 on <strong>LCQ</strong> <strong>Deca</strong> / <strong>LCQ</strong> <strong>Duo</strong><br />

◗ Infusion Flow Rate (µL/min.): 3-5<br />

◗ Spray Voltage (kV): 4-6<br />

◗ Spray Current (µA): 0.1-0.75<br />

◗ Sheath Gas Flow Rate (arb): 20-40<br />

◗ Aux. Gas Flow Rate (arb): 0<br />

◗ Capillary Temperature: 200-250°C<br />

◗ Probe Position : 2

<strong>LCQ</strong> <strong>Deca</strong> Tune Plus Window<br />

<strong>LCQ</strong> <strong>Deca</strong> Tune Plus Window<br />

(ESI Source dialog and Status Panel)

<strong>Troubleshooting</strong> the API2 Probe<br />

◗ Contamination: Wipe spray shield around heated capillary<br />

Wipe out ESI probe flange<br />

Flush the ESI probe<br />

◗ Erratic spray: Sample tube<br />

Sheath gas flow<br />

◗ Spray Current too high: Problematic mixture of solvents/sample/etc.<br />

◗ Erratic Spray Voltage: Spray current at maximum<br />

◗ Overall solution for 90% of source related Problems:<br />

� Good maintenance<br />

(especially with the sample tube)<br />

� Use of divert valve

API-2 API 2 / ESI Probe Assembly<br />

Cross Section

API-2 API 2 / Off Axis ESI Probe<br />

(<strong>LCQ</strong> <strong>Deca</strong> / <strong>LCQ</strong> <strong>Duo</strong> / <strong>LCQ</strong> Classic)

API-2 API 2 / Off Axis ESI<br />

Tangential Movement<br />

Probe Geometry<br />

ESI probe on a 25 degree slide<br />

Ion flow<br />

Heated<br />

Capillary<br />

matrix flow

API-2 API 2 / Off Axis ESI Guidelines<br />

LC Flow Rates<br />

Infusion or LC at flow<br />

rates of 200 µL/min<br />

Slide<br />

Plate<br />

Position<br />

Operational Parameters<br />

Probe<br />

Position<br />

(1 to 7)<br />

Heated<br />

Capillary<br />

Temperature<br />

Top 4 Typical setting:<br />

250 °C<br />

Top 4 Typical setting:<br />

350 °C<br />

Top 5 Typical setting:<br />

350 °C<br />

Sheath<br />

Gas<br />

Required<br />

Typical setting:<br />

10 to 30 units<br />

Required<br />

Typical setting:<br />

80+ units<br />

Required<br />

Typical setting:<br />

80+ units<br />

Auxiliary<br />

Gas<br />

Not required<br />

Typical<br />

setting:<br />

0 units<br />

Required<br />

Typical<br />

setting:<br />

10 to 20 units<br />

Required<br />

Typical<br />

setting:<br />

10 to 20 units

APCI Ionization Process

<strong>LCQ</strong> Classic APCI Probe

<strong>LCQ</strong> <strong>Deca</strong> / <strong>LCQ</strong> <strong>Duo</strong> APCI Probe

Typical APCI Tune Parameters<br />

Conditions: Reserpine at 1ml/min<br />

◗ Vaporizer Temp (°C): 400-550 (600 max.)<br />

◗ Discharge Current (µA): 5 (10µA max.)<br />

◗ Discharge Voltage (kV): 4-6kV (read back)<br />

◗ Sheath Gas Flow Rate (arb): 50-80<br />

◗ Aux. Gas Flow Rate (arb): 0-20<br />

◗ Capillary Temp (°C): 125-250<br />

◗ Capillary Voltage (V): 10-40<br />

◗ Tube Lens Offset (V): 30-60<br />

◗ Flow Rate capability: 50µL/min. - 2mL/min.

<strong>LCQ</strong> <strong>Deca</strong> Tune Plus Window<br />

<strong>LCQ</strong> <strong>Deca</strong> Tune Plus Window<br />

APCI Source dialog and Status Panel

<strong>Troubleshooting</strong> the APCI Probe<br />

◗ Spray voltage erratic: Spray current should not exceed 20µA<br />

Once 20µA level is reached, the spray<br />

voltage will be lowered to compensate<br />

for the 20µA threshold<br />

◗ Spray current too high: Problematic mixture of solvents/sample/etc.<br />

◗ Contamination: Bake out the probe for 10-60 minutes at 50ºC<br />

above desired Vaporizer Temperature<br />

◗ Lack of sensitivity: Make sure the corona needle is seated<br />

and is not deformed

API-1 API 1 / API-2 API 2 APCI Probe<br />

Cross Section

Ion Transfer / Desolvation Process<br />

Overview<br />

ESI Nozzle<br />

(± ± 8 kV)<br />

Solvent/Buffer<br />

+<br />

+<br />

+<br />

+<br />

+<br />

+<br />

+<br />

Heated Capillary<br />

+ +<br />

+<br />

Ion<br />

Stream

<strong>LCQ</strong> API Stack Gas Flow<br />

1 Torr<br />

×<br />

×<br />

Tube lens<br />

Peek Holder<br />

skimmer<br />

10 -3 Torr

<strong>LCQ</strong> API Stack Assembly<br />

Cross Section<br />

Kalrez OO-Ring<br />

OO-Ring<br />

Ring<br />

Capillary must be flush with the<br />

Tube lens and Skimmer Mount.<br />

Peek Bushing<br />

Capillary Sleeve<br />

Manifold<br />

Manifold<br />

Heated Capillary Specifications:<br />

Heater Resistance: 14Ω<br />

Platinum Sensor: 110Ω

Cal Mix Tune Parameters<br />

<strong>LCQ</strong> API Stack<br />

◗ Capillary Temp (°C)*: 200-250<br />

◗ Capillary Voltage (V): 10-40<br />

◗ Tube Lens Offset (V): 30-60<br />

* Heated Capillary I.D.:<br />

<strong>LCQ</strong> Classic / <strong>LCQ</strong> <strong>Duo</strong>: 400µm<br />

<strong>LCQ</strong> <strong>Deca</strong>: 500µm

<strong>LCQ</strong> <strong>Deca</strong> Tune Plus Window<br />

<strong>LCQ</strong> <strong>Deca</strong> Tune Plus Window<br />

Vacuum dialog and Status Panel

<strong>Troubleshooting</strong> the API Stack<br />

◗ Loss of Sensitivity: Clean skimmer and tube lens<br />

◗ Low Convectron Gauge Pressure: Heated capillary plugged<br />

◗ Cal Mix Contamination: Clean API probe and heated capillary area<br />

◗ Spiky noise: Bent capillary tip or dirty heated capillary<br />

◗ Constant Background: Possible heated capillary contamination<br />

◗ Overall solution for 90% of API Stack related Problems:<br />

� Good maintenance:<br />

Caution:<br />

Clean/Rinse the heated capillary region<br />

and spray shield daily.<br />

� Use of the divert valve<br />

� Use of Spray Cap and Orthogonal<br />

Sampling Adapter<br />

Periodically empty the waste bottle to avoid potential back streaming of waste<br />

solvent into the source region.

Orthogonal Spray Adapter<br />

Configuration<br />

ESI Probe<br />

Buffer deposition<br />

‘Orthogonal’ ion flow<br />

Focusing ring Liquid drains<br />

Heated capillary

Orthogonal Spray Adapter Guidelines<br />

Operational Parameters<br />

LC Flow Rate<br />

Infusion or LC at flow<br />

rates of

ESI Probe<br />

Reduces Cal Mix contamination<br />

Spray Cap<br />

Configuration<br />

Spray Cap<br />

Capillary Sleeve<br />

Heated capillary<br />

Spray Shield<br />

O-Ring Ring<br />

Peek<br />

Bushing<br />

Spray Shield

Spiky Noise Characteristics<br />

Single Noise Spike<br />

S#: 4 RT: 0.27 AV: 1 T: + p Full ms NL: 2185325<br />

Abundance<br />

ve<br />

elati<br />

R<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

330.5<br />

326.6 328.6 330.9<br />

334.3<br />

327.6 328.0 329.0<br />

331.8<br />

334.6<br />

326 327 328 329 330 331 332 333 334 335<br />

m/z<br />

335.6

Spiky Noise Characteristics<br />

S#: 4 RT: 0.27 AV: 1 T: + p Full ms NL: 7692800<br />

100<br />

90<br />

80<br />

70<br />

60<br />

Abundance 50<br />

e<br />

elativ<br />

elativ<br />

R 40<br />

30<br />

20<br />

10<br />

0<br />

308.5<br />

330.5<br />

Particle Noise Spectrum of Cal mix<br />

Spiky Noise at 10 uscans<br />

524.4<br />

536.3<br />

195.2<br />

262.7<br />

413.3<br />

553.7<br />

690.9<br />

812.2<br />

959.6<br />

872.7 1022.3<br />

1122.1<br />

1222.1<br />

1322.1<br />

1421.9<br />

1522.0<br />

1621.8<br />

1721.9<br />

200 400 600 800 1000<br />

m/z<br />

1200 1400 1600 1800<br />

1821.8

Heated Capillary Cross Section<br />

Bent Capillary Tip<br />

Heated<br />

Capillary<br />

Bent Capillary Tip<br />

+<br />

+<br />

+<br />

+<br />

+<br />

+<br />

+<br />

+<br />

+ +<br />

+<br />

+<br />

+ +<br />

+ +<br />

+<br />

+<br />

+<br />

Tube<br />

Lens<br />

Fixed<br />

distance<br />

Skimmer<br />

With time, compound will<br />

neutralize out on the skimmer.<br />

This will spot will eventually<br />

need to be cleaned; otherwise,<br />

field affects can reduce<br />

sensitivity.<br />

Avoid bending the tip of the heated<br />

capillary. The tip of the capillary<br />

must remain off axis to the<br />

skimmer; otherwise, spiky noise or<br />

reduced sensitivity can occur.<br />

The distance between the end of<br />

the capillary and the skimmer<br />

opening must remain fixed.

Ion Transfer Overview<br />

<strong>Deca</strong> Ion Optic System<br />

Ions will be trapped<br />

in stable trajectories<br />

Ion Stream<br />

from skimmer<br />

Transfer<br />

Array<br />

Fundamental RF<br />

on Ring<br />

Ion Trap

Octapole 1 Offset: <strong>LCQ</strong> / <strong>LCQ</strong> <strong>Duo</strong><br />

Quadrupole 1 Offset: <strong>LCQ</strong> <strong>Deca</strong><br />

Ion Optics<br />

Gating Ions into the Ion Trap<br />

Multipole RF<br />

Octapole 2 2 Offset:<br />

Offset:<br />

<strong>LCQ</strong> / <strong>LCQ</strong> <strong>Duo</strong> / <strong>LCQ</strong> <strong>Deca</strong>

<strong>LCQ</strong> <strong>Deca</strong> Tune Plus Window<br />

<strong>LCQ</strong> <strong>Deca</strong> Tune Plus Window<br />

Ion Optics dialog and Status Panel

Cal Mix Tune Parameters<br />

<strong>LCQ</strong> Ion Optics<br />

Octapole 1 Offset (V) for Classic/<strong>Duo</strong>: -1 to -5<br />

Octapole 1 Offset (V) for <strong>Deca</strong>: -4 to -9<br />

Lens Voltage (v): -16 to -50<br />

Octapole 2 Offset (V) for Classic / <strong>Duo</strong>: -5.5 to -10<br />

Octapole 2 Offset (V) for <strong>Deca</strong>: -7 to -15<br />

Octapole RF Amplitude (V p-p): 400<br />

Entrance Lens (V) for the <strong>Deca</strong> only: -35 to -60 V<br />

<strong>Troubleshooting</strong>:<br />

Loss of Sensitivity: * Clean octapoles(multipoles) and lens<br />

Octapole Diagnostic errors: * Tune multipole RF prior to running diagnostics.<br />

* Multipole RF tune now performed in calibration<br />

for all <strong>LCQ</strong>s run with Xcalibur.

760 torr<br />

<strong>LCQ</strong> Classic Optics<br />

Typical Operating Pressures<br />

1.0 torr 1.7x10 -3 torr<br />

30 m 3 /hr<br />

100 L/sec<br />

2.0 x10 -5 torr (1.0x10 -5 torr He)<br />

3.5x10 -3 torr He<br />

220 L/sec

<strong>LCQ</strong> <strong>Duo</strong> Optics<br />

Typical Operating Pressures/Comparison to <strong>LCQ</strong> Classic<br />

1.0 torr 1.7x10-3 760 torr torr 2.0 x10-5 torr (1.0x10-5 torr He)<br />

30 m 3 /hr<br />

100 L/sec<br />

3.5x10 -3 torr He<br />

220 L/sec

<strong>LCQ</strong> <strong>Deca</strong> Optics<br />

Typical Operating Pressures/Comparison to <strong>LCQ</strong> Classic<br />

1.3 torr 1.7x10-3 760 torr torr 2.0 x10-5 torr (1.0x10-5 torr He)<br />

60 m 3 /hr<br />

100 L/sec<br />

3.5x10 -3 torr He<br />

220 L/sec

Potential<br />

Potential Energy Diagram<br />

<strong>LCQ</strong> and <strong>LCQ</strong> <strong>Duo</strong><br />

0<br />

4000<br />

20<br />

Source CID<br />

= 20%<br />

50<br />

0<br />

-3<br />

-23<br />

-20<br />

-40<br />

-7<br />

-27<br />

-10<br />

-30<br />

-15000

Potential<br />

Potential Energy Diagram<br />

<strong>LCQ</strong> <strong>Deca</strong><br />

0<br />

4000<br />

50<br />

20<br />

0<br />

-5<br />

-20<br />

-7 -10<br />

-50<br />

-15000

RF Tune Diagnostic Dialog<br />

RF Tune Diagnostic Dialog<br />

<strong>LCQ</strong> <strong>Deca</strong>

Tune Multipole RF<br />

Tune Multipole RF<br />

<strong>LCQ</strong> <strong>Deca</strong>

Multipole RF Tune<br />

in Calibration Process<br />

Multipole RF Tune<br />

verification performed<br />

prior to calibration.

<strong>LCQ</strong> <strong>Deca</strong> Ion Optics<br />

Specifics Features<br />

Square Square Quadrupole<br />

Quadrupole<br />

New New Endcap Endcap Electrodes<br />

Electrodes<br />

New New Entrance Entrance Lens<br />

Lens<br />

New New Inter-Octapole Inter-Octapole Inter Octapole Lens<br />

Lens

Split Multipole<br />

<strong>Deca</strong> / <strong>Duo</strong> Configurations<br />

Split Square Quadrupole<br />

<strong>LCQ</strong> <strong>Deca</strong><br />

Deflection - set to +132<br />

Transmit - both set to Offset Value<br />

Split Octopole<br />

<strong>LCQ</strong> <strong>Duo</strong><br />

Deflection - set to -132

Relative Abundance<br />

Relative Abundance<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

0<br />

Effect of Split Multipole<br />

No Split<br />

Multipole<br />

200 300 400 500 600 700 800 900<br />

m/z<br />

With Split<br />

Multipole<br />

MRFA<br />

m/z 524<br />

(with isotopes)<br />

MRFA<br />

m/z 524<br />

(with isotopes)<br />

200 300 400 500 600 700 800 900

-DC<br />

<strong>LCQ</strong> <strong>Deca</strong> Noise Reduction<br />

Split DC on Scan out<br />

No Split<br />

+DC<br />

DECA<br />

<strong>LCQ</strong><br />

Pulsed lens

Overview of Ion Separation<br />

Quadrupole Ion Trap<br />

Ion Stream<br />

from Transfer Array<br />

Ion Trap<br />

Fundamental (Ring Electrode) and Resonance Ejection (End Caps) RF potential<br />

are ramped to sequentially eject ions from the Ion Trap

Mass Selective Instability<br />

Simplified Overview<br />

0.2<br />

0.1<br />

0<br />

-0.1<br />

-0.2<br />

-0.3<br />

-0.4<br />

-0.5<br />

-0.6<br />

-0.7<br />

a z<br />

0.2<br />

β z<br />

0.3<br />

0.4 0.5 0.6 0.7 0.81.0<br />

0<br />

0.1<br />

0.2<br />

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6<br />

0.3<br />

0.4<br />

0.5<br />

β<br />

0.6 r<br />

0.7<br />

0.8<br />

0.9<br />

1.0<br />

q z-edge = 0.908<br />

q z = k v<br />

(m/z)<br />

q z

Ion Trap Mass Analyzer<br />

Ion Trap Mass Analyzer<br />

Filter Ions

Quadrupole Ion Trap<br />

Operational Parameters<br />

◗ Main RF: 16.2 kV p-p max.<br />

(760kHz)<br />

◗ Resonance Ejection RF: 80 V p-p max.<br />

(frequency Varies)<br />

◗ Waveform RF: 160 V p-p max.<br />

(Arbitrary)<br />

◗ Trap Offset: 10 V fixed<br />

◗ Exit Lens: at Ground potential<br />

◗ Helium gas consumption: 1 cc/min. under<br />

vacuum

<strong>LCQ</strong> <strong>Deca</strong> Tune Plus Window<br />

<strong>LCQ</strong> <strong>Deca</strong> Tune Plus Window<br />

Injection Control dialog and Status Panel

<strong>Troubleshooting</strong> the Ion Trap<br />

◗ Loss of Sensitivity: Clean End caps and ring electrode<br />

◗ High Mass Noise: Clean spacer rings and endcaps.<br />

◗ Lack of sensitivity/resolution/mass stability:<br />

Lack of helium or Air leak<br />

Notes:<br />

Full scan target: -Set to 5X10e7 for best sensitivity<br />

in the positive ion mode.<br />

-For best mass stability results, set to 2X10e7.<br />

-Set (2-3) times less in the negative ion mode.<br />

A typical value of 1X10e7 should be used.<br />

Positive/Negative switching: -Xcalibur allows for separate tune <strong>files</strong>.<br />

Pos/Neg scan segments can be used.<br />

ZoomScan target: -Set to (1-3)X10e6 for compounds with<br />

multiple charge.<br />

-Singly charged compounds will exhibit a<br />

slightly higher target.<br />

-For calibration with Cal Mix, set to 1X10e7.

Tune RF Frequency<br />

<strong>LCQ</strong> <strong>Deca</strong><br />

Measure RF<br />

Frequency<br />

Detected RF<br />

RF Frequency<br />

Well<br />

Standing Wave<br />

Ratio<br />

Switch Status

Tune RF Modulation<br />

<strong>LCQ</strong> <strong>Deca</strong><br />

Standing<br />

Wave<br />

Ratio<br />

Switch Status<br />

Detected RF<br />

Highest Mass<br />

RF Modulation<br />

Upper<br />

and<br />

Lower<br />

Ranges<br />

RF Modulation

S#: 34 RT: 1.11 AV: 1 T: + p ms NL: 10610<br />

Abundance<br />

ve<br />

elati<br />

R<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

High Mass Noise<br />

901.9<br />

951.5<br />

1196.3<br />

1229.1<br />

1336.0<br />

1504.0<br />

200 400 600 800 1000 1200 1400 1600<br />

m/z<br />

1641.4<br />

1628.6<br />

High Mass noise due to a RF electrical discharge from inside the manifold.<br />

17

Affects of Helium on Spectra<br />

Helium Helium flowing flowing into into trap<br />

trap<br />

S#:1 RT:0.00 AV:1 SM:7G NL:2.50E7<br />

T: + p Full ms<br />

Relative Abundance<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

524.3<br />

525.3<br />

514 516 518 520 522<br />

m/z<br />

524 526 528<br />

Helium Helium shut shut off off and and not not flowing flowing into into trap<br />

trap<br />

S#:1 RT:0.02 AV:1 SM:7G NL:9.70E6<br />

T: + p Full ms<br />

Relative Abundance<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

520.7<br />

521.8<br />

521.2<br />

522.6 523.0 523.0<br />

523.9<br />

514 516 518 520 522<br />

m/z<br />

524 526 528<br />

S#:23-32 RT:0.71-1.00 AV:10 SM:7G NL:5.61E7<br />

T: + p Full ms<br />

Relative Abundance<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

195.15<br />

524.26<br />

1322.06<br />

1222.14<br />

1522.04<br />

1621.97<br />

1721.89<br />

1821.95<br />

1122.21 1921.88<br />

1022.09<br />

500 1000<br />

m/z<br />

1500 2000<br />

S#:23-32 RT:0.39-0.54 AV:10 SM:7G NL:2.80E7<br />

T: + p Full ms<br />

Relative Abundance<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

192.17<br />

1320.95<br />

1620.79<br />

1520.26<br />

1720.44<br />

1220.75<br />

523.01 1919.96<br />

1120.90<br />

500 1000<br />

m/z<br />

1500 2000

Ion Detection

2-Particles<br />

enter the<br />

multiplier<br />

Electron Multiplier<br />

Detection System<br />

Cathode<br />

Applied High<br />

Voltage<br />

Anode cup<br />

~<br />

Two particles formed when an ion<br />

ejected from the Ion Trap hits the<br />

dynode. Dynode particles enter the<br />

multiplier.<br />

Each particle hits the surface of the<br />

multiplier resulting in the ejection of<br />

two more particles.<br />

The cascading effect of this process<br />

will produce a charge on the anode<br />

cup.<br />

This charge represents the signal<br />

produced by the ion.<br />

Signal to Data system.

<strong>LCQ</strong> <strong>Deca</strong> Tune Plus Window<br />

<strong>LCQ</strong> <strong>Deca</strong> Tune Plus Window<br />

Ion Detection System dialog and Status Panel

Detection System Parameters<br />

◗ Dynode Voltage: 15kV (fixed)<br />

◗ Electron Multiplier: 2500 Volts max.<br />

Note:<br />

– Multiplier voltage is a calibrated parameter.<br />

– For best results, the multiplier should not be set manually.<br />

<strong>Troubleshooting</strong>:<br />

No peaks on Classic: Check multiplier voltage<br />

Switch dynode polarity<br />

Check for ions<br />

No peaks on <strong>Deca</strong>/<strong>Duo</strong>: Check Multiplier and Dynode Voltages.<br />

Noisy spectra with heated capillary capped off:<br />

Potential Dynode noise<br />

Clean Dynode Cup

Dynode Noise<br />

◗ Dynode noise occurs over time.<br />

◗ A noisy baseline with the heated<br />

capillary capped off is the<br />

symptom.<br />

◗ This is due to an accumulation of<br />

material that can build up in the<br />

dynode cup over time.<br />

◗ The cup should be cleaned when<br />

this occurs.

Voltage<br />

Life Time of the<br />

Electron Multiplier<br />

Time<br />

The voltage needed to produce gain on the multiplier should show a linear increase with time.

<strong>LCQ</strong> Recommended Maintenance Schedule<br />

Daily:<br />

Morning Recommendations:<br />

◗ Check the convectron and ion gauge pressures. Make sure the<br />

vacuum system is operational.<br />

◗ Check the fused silica sample tube. Make sure the fused silica has<br />

not elongated.<br />

◗ Remove the septum cap.<br />

◗ Check the convectron and ion gauges pressure again. Make sure<br />

the vacuum pressures are still OK.<br />

◗ Start your analysis.

<strong>LCQ</strong> Recommended Maintenance Schedule<br />

Daily:<br />

Evening Recommendations:<br />

◗ Put the system in the stand-by mode.<br />

◗ Turn off the Ion Gauge and rinse the Heated Capillary with methanol<br />

or an appropriate solvent. When finished, turn Ion Gauge back on.<br />

◗ Cap off the heated capillary with the septum cap.<br />

◗ Secure the API probe to the API stack.<br />

◗ Make sure the solvent waste bottle is empty.<br />

◗ Open the mechanical pump ballast for roughly 0.5 hour.<br />

◗ While the pump is ballasting, maintain (move, delete, and/or copy)<br />

<strong>files</strong> at the <strong>LCQ</strong> computer.<br />

◗ If bottled nitrogen gas is being used, check the nitrogen gas.<br />

◗ After 0.5 hour, close the ballast valve.

<strong>LCQ</strong> Recommended Maintenance Schedule<br />

Weekly:<br />

For normal operation:<br />

◗ Check the mech. pump oil level.<br />

◗ Fill the mech. pump as needed.<br />

◗ If through put is high (running 24 hours a day), schedule<br />

one day a week to:<br />

- Change the mech. pump oil.<br />

- Clean the skimmer and tube lens.

<strong>LCQ</strong> Recommended Maintenance Schedule<br />

Monthly:<br />

Every Month:<br />

◗ Check the helium gas tank pressure. Replace as needed.<br />

◗ Check the nitrogen gas tank (Dewer) pressure. Replace as needed.<br />

◗ Nitrogen gas consumption:<br />

– Typical: 3-6 L/min<br />

– Worse case scenario associated with choice of Nitrogen Generator:<br />

15L/min (28SCFH at 100psi and 99% purity) for <strong>LCQ</strong> Classic<br />

30L/min (56SCFH at 100psi and 99% purity) for <strong>Duo</strong> / <strong>Deca</strong><br />

◗ Check the <strong>LCQ</strong> calibration.<br />

◗ Check the air filter. Clean if necessary.<br />

◗ Possibly, change the mech. pump oil.

<strong>LCQ</strong> Recommended Maintenance Schedule<br />

Every 3 months:<br />

Change the mech. pump oil.<br />

6 months to a year:<br />

Change the turbo pump oil.<br />

Notes<br />

- The API stack and analyzer should be clean as needed.<br />

- If the sensitivity starts to drop off and can not be<br />

restored, clean the API stack (and analyzer) as needed.

Overview of Diagnostics<br />

◗ Tests and Tools provided:<br />

– Static Tests<br />

– Dynamic Tests<br />

– Diagnostic Tools<br />

– Research Tools<br />

◗ Limitations:<br />

– Provides status of electronics components<br />

– Does not provide readbacks from the actual source element<br />

Can not detect a broken or loose connection.<br />

◗ Prior to running the dynamic diagnostics:<br />

– Tune all RF components (Octapole/Multipole and Main RF).<br />

– Make sure the system in the ON mode.<br />

– Make sure the API Probe is bolted to the API stack. This allows the<br />

high voltage to be activated.

Run All Diagnostics<br />

Run All Diagnostics<br />

Dynamic and Static Tests

Static Results from Status Test<br />

+15 V - Pass<br />

+150 V - Pass<br />

+205 V - Pass<br />

+24 V - Pass<br />

+28 V - Pass<br />

+35 V - Pass<br />

+36 V - Pass<br />

+5 V - Pass<br />

-15 V - Pass<br />

-150 V - Pass<br />

-205 V - Pass<br />

-28 V - Pass<br />

8 kV PS voltage - Pass<br />

Ambient temp. - Pass<br />

Analyzer temp. - Pass<br />

Aux gas flow - Pass<br />

Capillary temp. - Pass<br />

Capillary voltage - Pass<br />

Convectron - Pass<br />

Detected RF - Pass<br />

Dynode voltage - Pass<br />

Entrance lens - Pass<br />

Intermultipole lens - Pass<br />

Ion gauge - Pass<br />

Main RF DAC - Pass<br />

Multiplier setting - Pass<br />

Multiplier voltage - Pass<br />

Multipole 1 offset - Pass<br />

Multipole 2 offset - Pass<br />

Multipole RF mod. - Pass<br />

Multipole det. RF - Pass<br />

Multipole RF amp. out - Pass<br />

RF amp. output - Pass<br />

RF det. temp. - Pass<br />

RF gen. temp. - Pass<br />

RF modulation - Pass<br />

Sheath gas flow - Pass<br />

Trap DC Offset - Pass<br />

Tube/gate lens - Pass

Dynamic Results<br />

RF Test<br />

Starting All Diagnostics Scan Tests<br />

16:18:30: Start scan readback test on device Auxiliary amplitude (V) -- 0 to 83.2<br />

16:18:35: Scan readback test ended<br />

16:18:37: Result: PASSED<br />

16:18:37: Start scan readback test on device Main RF DAC (16-bit) -- 0 to 65535<br />

16:18:42: Scan readback test ended<br />

16:18:44: Result: PASSED<br />

16:18:44: Start scan readback test on device Vernier det. RF amp. (V) -- 0 to 65535<br />

16:18:48: Scan readback test ended<br />

16:18:50: Result: PASSED<br />

16:18:50: Start scan readback test on device Vernier RF DAC (16-bit) -- 0 to 65535<br />

16:18:55: Scan readback test ended<br />

16:18:57: Result: PASSED<br />

16:18:57: Start scan readback test on device Multipole RF DAC (V) -- 0 to 1000<br />

16:19:02: Scan readback test ended<br />

16:19:04: Result: PASSED

Dynamic Test<br />

Dynamic Test<br />

Graphical Output

Starting All Diagnostics Scan Tests<br />

Dynamic Results<br />

Lenses Test<br />

16:19:04: Start scan readback test on device Multipole 1 offset (V) -- -132 to 132<br />

16:19:09: Scan readback test ended<br />

16:19:11: Result: PASSED<br />

16:19:11: Start scan readback test on device Multipole 2 offset (V) -- -132 to 132<br />

16:19:16: Scan readback test ended<br />

16:19:17: Result: PASSED<br />

16:19:17: Start scan readback test on device Multipole lens (V) -- -132 to 132<br />

16:19:22: Scan readback test ended<br />

16:19:24: Result: PASSED<br />

16:19:24: Start scan readback test on device Multipole det. RF amp. (Vp-p) -- 0 to 1000<br />

16:19:29: Scan readback test ended<br />

16:19:31: Result: PASSED

Dynamic Results<br />

Ion Detection Test<br />

Starting All Diagnostics Scan Tests<br />

16:19:31: Start scan readback test on device Trap Offset (V) -- -132 to 132<br />

16:19:36: Scan readback test ended<br />

16:19:38: Result: PASSED<br />

16:19:38: Start scan readback test on device Tube gate (V) -- -200 to 198.01<br />

16:19:43: Scan readback test ended<br />

16:19:45: Result: PASSED<br />

16:19:45: Start scan readback test on device Multiplier (V) -- 0 to -2200<br />

16:19:58: Scan readback test ended<br />

16:20:00: Result: PASSED

Dynamic Results<br />

API Source Test<br />

Starting All Diagnostics Scan Tests<br />

16:20:00: Start scan readback test on device Auxiliary gas flow (arb) -- 0 to 60<br />

16:21:35: Scan readback test ended<br />

16:21:37: Result: PASSED<br />

16:21:37: Start scan readback test on device Sheath gas flow (arb) -- 20 to 100<br />

16:23:20: Scan readback test ended<br />

16:23:22: Result: PASSED<br />

16:23:22: Start scan readback test on device Capillary Voltage (V) -- -132 to 132<br />

16:23:27: Scan readback test ended<br />

16:23:28: Result: PASSED<br />

16:23:28: Final result: PASSED

Power Supplies<br />

Power Supplies<br />

Static Diagnostic

API and Temperature<br />

API and Temperature<br />

Static Diagnostic

Lenses<br />

Static Diagnostic

RF<br />

RF-1<br />

Static Diagnostic

RF<br />

RF-2<br />

Static Diagnostic

Calibration<br />

Diagnostic Tool

Toggles/Detector<br />

Diagnostic Tool

Instrument Settings<br />

Instrument Settings<br />

Diagnostic Tool

Graphs<br />

Plotting Conversion Dynode Voltage

Graphs<br />

Plot Tube Lens Calibration

Triggers<br />

Research Tool

Front Panel LEDs<br />

Classic/<strong>Deca</strong>

Front Panel LEDs<br />

Front Panel LEDs<br />

Definition of Classic/<strong>Deca</strong><br />

�Power: Indication of the digital power<br />

– Should be green unless the power to the <strong>LCQ</strong> is off or there has been a failure.<br />

�Vacuum: Indicates that the vacuum is OK.<br />

– (Convectron gauge, ion gauge, and external switch are all in the correct state.)<br />

– Should be green. If any one of the inter-locks is not logically correct, the LED will be off.<br />

�Communication: Indicates communication between the on-board AT CPU and the NT<br />

computer.<br />

– Will be green if the two computers are communicating.<br />

– Will be yellow if the on-board AT is active but not communicating with the NT computer.<br />

– Will be off if the <strong>LCQ</strong> is off or if a failure has occurred.<br />

�System: Indicates the status of the <strong>LCQ</strong>.<br />

– Will be green if the <strong>LCQ</strong> is in the On mode. High voltage is applied.<br />

– Will be yellow if the <strong>LCQ</strong> is in the standby mode. High voltages are off.<br />

– Will be off if the <strong>LCQ</strong> is in the Off mode. Most of the power supplies are off.<br />

�Scan: Indicates that the <strong>LCQ</strong> is in the On mode and Scanning.<br />

– Will be blue and flashing when the <strong>LCQ</strong> is collecting data.<br />

– Will be off if the <strong>LCQ</strong> is either in the On or Standby mode. Also will be off if the <strong>LCQ</strong> is<br />

off.

Front Panel LEDs<br />

<strong>LCQ</strong> <strong>Duo</strong>

<strong>LCQ</strong> <strong>Duo</strong> Front Panel LEDs<br />

Definition<br />

�Power: Indication of the digital power<br />

– Should be green unless the power to the <strong>LCQ</strong> is off or there has been a failure.<br />

– Will flash yellow indicating a Warning condition for the on-board CPU temperature .<br />

– Will be solid yellow indicating a Fatal condition. The MS will be held in a Reset mode until<br />

the temperature problem has been resolved.<br />

�Vacuum: Indicates that the vacuum is OK.<br />

– (Convectron gauge, ion gauge, and external switch are all in the correct state.)<br />

– Should be green. If any one of the inter-locks is not logically correct, the LED will be off.<br />

�Communication: Indicates communication between the <strong>LCQ</strong> AT<br />

CPU and the NT computer.<br />

– Will be green if the two computers are communicating.<br />

– Will be yellow if the on-board AT is active but not communicating with the NT computer.<br />

– Will be off if the <strong>LCQ</strong> is off or if a failure has occurred.

<strong>LCQ</strong> <strong>Duo</strong> Front Panel LEDs<br />

Definition<br />

� System: Indicates the status of the <strong>LCQ</strong>.<br />

− Will be green if the <strong>LCQ</strong> is in the On mode. High voltage is applied.<br />

− Will be yellow if the <strong>LCQ</strong> is in the standby mode. High voltages are off.<br />

− Will be off if the <strong>LCQ</strong> is in the Off mode. Most of the power supplies are off.<br />

� Scan: Indicates that the <strong>LCQ</strong> is in the On mode and Scanning.<br />

− Will be blue and flashing when the <strong>LCQ</strong> is collecting data.<br />

− Will be off if the <strong>LCQ</strong> is either in the On or Standby mode. Also will be off<br />

if the <strong>LCQ</strong> is off.<br />

� Syringe Pump: Indicates the status of the syringe pump.<br />

− Will be green if the syringe pump on.<br />

− Will be yellow when the pump has reached it end of travel.