Bachelor of Engineering (Honours) in Mechanical Engineering

Bachelor of Engineering (Honours) in Mechanical Engineering

Bachelor of Engineering (Honours) in Mechanical Engineering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

B.Eng. (Hons.) <strong>in</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

<strong>Bachelor</strong> <strong>of</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> (<strong>Honours</strong>) <strong>in</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

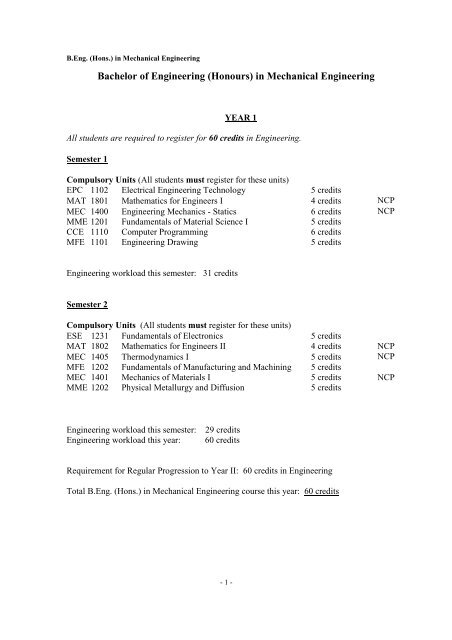

YEAR 1<br />

All students are required to register for 60 credits <strong>in</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong>.<br />

Semester 1<br />

Compulsory Units (All students must register for these units)<br />

EPC 1102 Electrical <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Technology 5 credits<br />

MAT 1801 Mathematics for Eng<strong>in</strong>eers I 4 credits NCP<br />

MEC 1400 <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics - Statics 6 credits NCP<br />

MME 1201 Fundamentals <strong>of</strong> Material Science I 5 credits<br />

CCE 1110 Computer Programm<strong>in</strong>g 6 credits<br />

MFE 1101 <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Draw<strong>in</strong>g<br />

5 credits<br />

<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> workload this semester: 31 credits<br />

Semester 2<br />

Compulsory Units (All students must register for these units)<br />

ESE 1231 Fundamentals <strong>of</strong> Electronics 5 credits<br />

MAT 1802 Mathematics for Eng<strong>in</strong>eers II 4 credits NCP<br />

MEC 1405 Thermodynamics I 5 credits NCP<br />

MFE 1202 Fundamentals <strong>of</strong> Manufactur<strong>in</strong>g and Mach<strong>in</strong><strong>in</strong>g 5 credits<br />

MEC 1401 Mechanics <strong>of</strong> Materials I 5 credits NCP<br />

MME 1202 Physical Metallurgy and Diffusion 5 credits<br />

<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> workload this semester: 29 credits<br />

<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> workload this year: 60 credits<br />

Requirement for Regular Progression to Year II: 60 credits <strong>in</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Total B.Eng. (Hons.) <strong>in</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> course this year: 60 credits<br />

- 1 -

B.Eng. (Hons.) <strong>in</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

YEAR 2<br />

All students are required to register for 60 credits <strong>in</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong>.<br />

Year (This unit starts <strong>in</strong> Semester 1 and cont<strong>in</strong>ues <strong>in</strong> Semester 2)<br />

Compulsory Unit<br />

SOR 1201 Probability, Sampl<strong>in</strong>g and Estimation 4 credits NCP<br />

Semester 1<br />

Compulsory Units (All students must register for these units)<br />

MFE 2105 <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Design Methods 2 credits<br />

MEC 2340 Fluid Mechanics I 5 credits NCP<br />

MFE 2101 <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Metrology 5 credits<br />

MEC 2300 <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics - K<strong>in</strong>ematics 5 credits NCP<br />

MME 2203 Ferrous and Non-Ferrous Metals 5 credits<br />

MEC 2308 Mechanics <strong>of</strong> Materials II 5 credits NCP<br />

<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> workload this semester: 29 credits (<strong>in</strong>clud<strong>in</strong>g half load <strong>of</strong> Year unit)<br />

Semester 2<br />

Compulsory Units (All students must register for these units)<br />

MAT 2814 Numerical Analysis with MATLAB 4 credits NCP<br />

MEC 2306 <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics – Dynamics 5 credits NCP<br />

SCE 2210 Introduction to Control Systems 5 credits<br />

MEC 2341 Fluid Mechanics II 5 credits NCP<br />

MEC 2307 Thermodynamics II 5 credits NCP<br />

MEC 2402 <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Components 5 credits<br />

<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> workload this semester: 31 credits (<strong>in</strong>clud<strong>in</strong>g half load <strong>of</strong> Year unit)<br />

<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> workload this year: 60 credits<br />

Requirement for Regular Progression to year III: 60 credits <strong>in</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Total B.Eng. (Hons.) <strong>in</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> course this year: 60 credits<br />

- 2 -

B.Eng. (Hons.) <strong>in</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> workload this year: 60 credits<br />

YEAR 3<br />

All students are required to register for 60 credits <strong>in</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong>. Students must register not less<br />

than 24 credits and not more than 36 credits <strong>in</strong> one semester.<br />

Year (This unit starts <strong>in</strong> Semester 1 and cont<strong>in</strong>ues <strong>in</strong> Semester 2)<br />

Compulsory Unit<br />

ENR 3000 F<strong>in</strong>al Year Project 18 credits NCP<br />

Semester 1<br />

Compulsory Units (All students must register for these units)<br />

MAT 3815 Mathematics for Eng<strong>in</strong>eers III 4 credits NCP<br />

MEC 3007 Vibration Analysis I 5 credits NCP<br />

MME 3206 Material Degradation 5 credits<br />

MEC 3400 Environmental <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> 5 credits<br />

Semester 2<br />

Compulsory Units (All students must register for these units)<br />

MEC 3008 Vibration Analysis II 5 credits NCP<br />

MEC 3103 Heat Transfer 5 credits NCP<br />

MEC 3302 Eng<strong>in</strong>eer <strong>in</strong> Society 3 credits<br />

Elective Units<br />

Choose study-units to the value <strong>of</strong> 10 credits from the follow<strong>in</strong>g list:<br />

Semester 1<br />

MFE 3102 Mechatronics Systems Design 5 credits<br />

MME 3207 Mechanics <strong>of</strong> Material Fracture 5 credits<br />

MFE 3107 Industrial Automation 5 credits<br />

MME 3205 Jo<strong>in</strong><strong>in</strong>g processes 5 credits<br />

Semester 2<br />

ENR 3301 <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Management 5 credits<br />

MFE 3207 Quality Management and Control 5 credits<br />

MFE 3201 Technologies <strong>in</strong> Mechatronic Systems 5 credits<br />

Requirement for successful completion <strong>of</strong> Year III (f<strong>in</strong>al year): 60 credits <strong>in</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Requirement for award <strong>of</strong> B.Eng. (Hons.) <strong>in</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> : 180 credits <strong>in</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Note: This course <strong>of</strong> study is governed by “The General Regulations for University<br />

Undergraduate Awards, 2004” and by the Bye-Laws…….<br />

- 3 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Study-units <strong>of</strong>fered by the<br />

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Faculty <strong>of</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

University <strong>of</strong> Malta<br />

- 1 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Level 1 units<br />

- 2 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC1400 - <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics – Statics<br />

Credits 6<br />

Lectures/tutorial hours<br />

Laboratory hours<br />

28 hours lectures, 14 hours tutorials<br />

Lecturer<br />

Prerequisites and exclusions<br />

Leads to<br />

Dr. Z. Sant<br />

MEC2300 - <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics - K<strong>in</strong>ematics, and<br />

MEC1401 - Mechanics <strong>of</strong> Materials 1<br />

Objectives This unit <strong>in</strong>troduces the concept <strong>of</strong> classical mechanics, the<br />

pr<strong>in</strong>ciples <strong>of</strong> model<strong>in</strong>g various loads and solv<strong>in</strong>g equilibrium<br />

between bodies connected by means <strong>of</strong> constra<strong>in</strong>s.<br />

Syllabus • Basic pr<strong>in</strong>ciples <strong>of</strong> Mechanics and Statics<br />

• Force systems and their description<br />

• Equivalence and equilibrium <strong>in</strong> Statics us<strong>in</strong>g vector<br />

algebra.<br />

• Applications <strong>of</strong> pr<strong>in</strong>ciple <strong>of</strong> equivalence - centroid <strong>of</strong><br />

area, centre <strong>of</strong> gravity.<br />

• Solid body constra<strong>in</strong>s and their characteristics<br />

• Equilibrium <strong>of</strong> a constra<strong>in</strong>ed solid body<br />

• System <strong>of</strong> coupled bodies <strong>in</strong> equilibrium. Trusses.<br />

• Friction and its application to mechanisms<br />

Laboratory work Can be either laboratory work, computer based project or any<br />

other assignment chosen by the course co-ord<strong>in</strong>ator<br />

Assessment 80% written exam<strong>in</strong>ation, 20% assignment<br />

Text books and resources • Meriam J.L., Kraig L.G., <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics – Statics<br />

• Hibbeler R. C., <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics – Statics<br />

- 3 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC1401 - Mechanics <strong>of</strong> Materials I<br />

Credits 5<br />

Lectures/tutorial hours<br />

Laboratory hours<br />

28 hours lectures, 7 hours tutorials<br />

Lecturer<br />

Dr. Z. Sant<br />

Prerequisites and exclusions MEC1400 - <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics – Statics<br />

Leads to MEC2308 - Mechanics <strong>of</strong> Materials II<br />

Objectives This unit <strong>in</strong>troduces the fundamental pr<strong>in</strong>ciples <strong>of</strong> solid<br />

mechanics. Theories related to the relationships between the<br />

external loads applied to a deformable body and the stress<br />

<strong>in</strong>tensities with<strong>in</strong> the body are studied and then applied to<br />

practical problems.<br />

Syllabus • Introduction to Mechanics <strong>of</strong> Materials – mechanical<br />

properties <strong>of</strong> materials, stress v.s. stra<strong>in</strong> curves, direct stresses,<br />

average shear stress, factor <strong>of</strong> safety, stress concentrations;<br />

• Tension/Compression – normal stress, deformation, stra<strong>in</strong><br />

energy;<br />

• Torsion – the elastic torsion <strong>of</strong> circular cross-sections, shear<br />

stress, deflection, stra<strong>in</strong> energy;<br />

• Bend<strong>in</strong>g <strong>of</strong> beams – the simple theory <strong>of</strong> pure bend<strong>in</strong>g,<br />

second moment <strong>of</strong> area and section modulus <strong>of</strong> beam cross<br />

sections, beams with un-symmetrical cross section, composite<br />

beams, bend<strong>in</strong>g <strong>of</strong> <strong>in</strong>itially curved beams, bend<strong>in</strong>g stress,<br />

stra<strong>in</strong> energy;<br />

• Shear stress distribution <strong>in</strong> beams – the relationship<br />

between bend<strong>in</strong>g moment, shear<strong>in</strong>g force and <strong>in</strong>tensity <strong>of</strong><br />

load<strong>in</strong>g, vertical shear stresses <strong>in</strong> beams, horizontal shear<br />

stresses, shear centre;<br />

• Slope and deflection <strong>of</strong> beams - relationship between<br />

load<strong>in</strong>g, shear<strong>in</strong>g force, bend<strong>in</strong>g moment, slope and<br />

deflection.<br />

• Deflection <strong>of</strong> beams and frameworks - energy methods,<br />

Castigliano’s theorems;<br />

• Comb<strong>in</strong>ed loads – the pr<strong>in</strong>ciple <strong>of</strong> superposition applied to<br />

bend<strong>in</strong>g stresses, direct stresses and shear stresses, skew or<br />

unsymmetrical bend<strong>in</strong>g.<br />

• Euler’s theory <strong>of</strong> elastic buckl<strong>in</strong>g<br />

Laboratory work Can be either laboratory work, computer based project or any<br />

other assignment chosen by the course co-ord<strong>in</strong>ator<br />

Assessment 80% written exam<strong>in</strong>ation, 20% assignment<br />

Text books and resources • Mechanics <strong>of</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Materials, P.P. Benham, R.J.<br />

Crawford, C.G. Armstrong<br />

• Mechanics <strong>of</strong> Materials, E.P. Popov<br />

- 4 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC1405 - Thermodynamics I<br />

Credits 5<br />

Lectures/tutorial hours 28 hours lectures<br />

Laboratory hours 6 hours<br />

Lecturer Dr. M. Farrugia<br />

Prerequisites and exclusions<br />

Leads to MEC2307 - Thermodynamics II<br />

Objectives This unit <strong>in</strong>troduces the basic concepts <strong>of</strong> thermodynamics,<br />

the laws <strong>of</strong> thermodynamics, and mixtures<br />

Syllabus • Fundamental concepts<br />

Equation <strong>of</strong> state, Internal energy, Enthalpy.<br />

Zeroth Law, and First Law <strong>of</strong> Thermodynamics.<br />

• Non-Flow Processes for gases and Vapour<br />

Properties <strong>of</strong> Liquids and Vapour (Steam), Use <strong>of</strong><br />

Tables and Charts for steam.<br />

Steady Flow and Non-Flow Energy<br />

Equation. Application <strong>of</strong> the Energy Equation to Non-<br />

Flow and Flow problems, Fill<strong>in</strong>g <strong>of</strong> a rigid vessel from<br />

a ma<strong>in</strong> (non-steady).<br />

• Second Law <strong>of</strong> Thermodynamics, Carnot Cycle,<br />

Absolute thermodynamic Temperature Scale, Entropy<br />

and Reversibility, General thermodynamic relations.<br />

Exergy. Corollaries <strong>of</strong> the second Law.<br />

• Properties <strong>of</strong> Mixtures: Perfect gas mixtures; P, V, T<br />

relationship, Parts <strong>of</strong> mass; Parts <strong>of</strong> volume; Internal<br />

energy; Enthalpy; Specific heats and entropy <strong>of</strong><br />

mixtures; Gas and vapour mixtures; Psychiometric<br />

chart.<br />

Laboratory work Polytropic Processes, Marcet Boiler, Heat Pump, Latent heat<br />

<strong>of</strong> vaporization, Heat balance on IC eng<strong>in</strong>e<br />

Assessment 90% written exam<strong>in</strong>ation, 10% practical<br />

Text books and resources • Eastop and McConkey, Applied Thermodynamics for<br />

<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Technologists.<br />

• Rogers & Mayhew, <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Thermodynamics<br />

Work and Heat Transfer<br />

- 5 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Level 2 units<br />

- 6 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC2300 - <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics - K<strong>in</strong>ematics<br />

Credits 5<br />

Lectures/tutorial hours<br />

Laboratory hours<br />

28 hours lectures, 7 hours tutorials<br />

Lecturer<br />

Dr. Z. Sant<br />

Prerequisites and exclusions MEC 400 - <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics - Statics<br />

Leads to MEC 2306 - <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics – Dynamics<br />

Objectives This unit <strong>in</strong>troduces the concept <strong>of</strong> movement analysis and<br />

characterization by means <strong>of</strong> path traveled, velocity, and<br />

acceleration for different types <strong>of</strong> motion.<br />

Syllabus • K<strong>in</strong>ematics <strong>of</strong> a Particle<br />

• K<strong>in</strong>ematics <strong>of</strong> System <strong>of</strong> Particles – rectil<strong>in</strong>ear motion,<br />

curvil<strong>in</strong>ear motion<br />

• Harmonic motion<br />

• Orthogonal Transformation <strong>of</strong> Vectors<br />

• Body Motion Characteristics – velocity and acceleration<br />

due to translation, rotation, general planar motion,<br />

spherical motion, general space motion<br />

• K<strong>in</strong>ematic Analysis <strong>of</strong> Planar Mechanisms – velocity<br />

and acceleration us<strong>in</strong>g analytical, grapho-analytical, and<br />

matrix method<br />

• K<strong>in</strong>ematic Analysis <strong>of</strong> Space Mechanisms – velocity<br />

and acceleration, relative velocity and acceleration us<strong>in</strong>g<br />

analytical, grapho-analytical, and matrix method.<br />

• Applications <strong>of</strong> k<strong>in</strong>ematic analysis to gear systems,<br />

Planet Mechanisms, and cams.<br />

Laboratory work Can be either laboratory work, computer based project or any<br />

other assignment chosen by the course co-ord<strong>in</strong>ator<br />

Assessment 80% written exam<strong>in</strong>ation, 20% assignment<br />

Text books and resources • Meriam J.L., Kraig L.G., <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics –<br />

Dynamics<br />

• Hibbeler R. C., <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics – Dynamics<br />

- 7 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

This unit is <strong>of</strong>fered to the B.Sc. (Hons.) Degree – Chemistry with Materials<br />

Unit Name MEC2303 - Mechanics <strong>of</strong> Materials for Scientists<br />

Credits 5<br />

Lectures/tutorial hours<br />

Laboratory hours<br />

28 hours lectures, 7 hours tutorials<br />

Lecturer<br />

Dr. Z. Sant<br />

Prerequisites and exclusions MEC1400 - <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics – Statics<br />

Leads to MEC2308 - Mechanics <strong>of</strong> Materials II<br />

Objectives This unit <strong>in</strong>troduces the fundamental pr<strong>in</strong>ciples <strong>of</strong> solid<br />

mechanics. Theories related to the relationships between the<br />

external loads applied to a deformable body and the stress<br />

<strong>in</strong>tensities with<strong>in</strong> the body are studied and then applied to<br />

practical problems.<br />

Syllabus • Introduction to Mechanics <strong>of</strong> Materials – mechanical<br />

properties <strong>of</strong> materials, stress v.s. stra<strong>in</strong> curves, direct stresses,<br />

average shear stress, factor <strong>of</strong> safety, stress concentrations;<br />

• Tension/Compression – normal stress, deformation, stra<strong>in</strong><br />

energy;<br />

• Torsion – the elastic torsion <strong>of</strong> circular cross-sections, shear<br />

stress, deflection, stra<strong>in</strong> energy;<br />

• Bend<strong>in</strong>g <strong>of</strong> beams – the simple theory <strong>of</strong> pure bend<strong>in</strong>g,<br />

second moment <strong>of</strong> area and section modulus <strong>of</strong> beam cross<br />

sections, beams with un-symmetrical cross section, composite<br />

beams, bend<strong>in</strong>g <strong>of</strong> <strong>in</strong>itially curved beams, bend<strong>in</strong>g stress,<br />

stra<strong>in</strong> energy;<br />

• Shear stress distribution <strong>in</strong> beams – the relationship<br />

between bend<strong>in</strong>g moment, shear<strong>in</strong>g force and <strong>in</strong>tensity <strong>of</strong><br />

load<strong>in</strong>g, vertical shear stresses <strong>in</strong> beams, horizontal shear<br />

stresses, shear centre;<br />

• Slope and deflection <strong>of</strong> beams - relationship between<br />

load<strong>in</strong>g, shear<strong>in</strong>g force, bend<strong>in</strong>g moment, slope and<br />

deflection.<br />

• Deflection <strong>of</strong> beams and frameworks - energy methods,<br />

Castigliano’s theorems;<br />

• Comb<strong>in</strong>ed loads – the pr<strong>in</strong>ciple <strong>of</strong> superposition applied to<br />

bend<strong>in</strong>g stresses, direct stresses and shear stresses, skew or<br />

unsymmetrical bend<strong>in</strong>g.<br />

• Euler’s theory <strong>of</strong> elastic buckl<strong>in</strong>g<br />

Laboratory work Can be either laboratory work, computer based project or any<br />

other assignment chosen by the course co-ord<strong>in</strong>ator<br />

Assessment 80% written exam<strong>in</strong>ation, 20% assignment<br />

Text books and resources • Mechanics <strong>of</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Materials, P.P. Benham, R.J.<br />

Crawford, C.G. Armstrong<br />

• Mechanics <strong>of</strong> Materials, E.P. Popov<br />

- 8 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC2306 - <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics - Dynamics<br />

Credits 5<br />

Lectures/tutorial hours<br />

Laboratory hours<br />

28 hours lectures, 7 hours tutorials<br />

Lecturer<br />

Dr. P. Mollicone<br />

Prerequisites and exclusions MEC2300 - <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics - K<strong>in</strong>ematics<br />

Leads to MEC3007 – Vibration Analysis I<br />

Objectives<br />

Syllabus<br />

• Basic pr<strong>in</strong>ciples <strong>in</strong> dynamics – Newton’s law, Momentum,<br />

Impulse, D’Alembert’s pr<strong>in</strong>ciple, Work and Energy<br />

• Dynamics <strong>of</strong> a particle<br />

• Dynamics <strong>of</strong> system <strong>of</strong> particles<br />

• Moment <strong>of</strong> <strong>in</strong>ertia and its transformation, pr<strong>in</strong>cipal axes and<br />

pr<strong>in</strong>cipal moments <strong>of</strong> <strong>in</strong>ertia<br />

• Dynamics <strong>of</strong> rigid body due to – translation, rotation,<br />

general planar motion, spherical motion, general space<br />

motion<br />

• Dynamics <strong>of</strong> mechanisms<br />

• Rotor dynamics<br />

• Impact <strong>of</strong> solid bodies<br />

• Basic pr<strong>in</strong>ciples <strong>in</strong> analytical dynamics: Virtual Work,<br />

Lagrange Equations<br />

Laboratory work Can be either laboratory work, computer based project or any<br />

other assignment chosen by the course co-ord<strong>in</strong>ator<br />

Assessment 80% written exam<strong>in</strong>ation, 20% assignment<br />

Text books and resources • Meriam J.L., Kraig L.G., <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics –<br />

Dynamics<br />

• Hibbeler R. C., <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics – Dynamics<br />

- 9 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC2307 - Thermodynamics II<br />

Credits 5<br />

Lectures/tutorial hours 28 hours lectures<br />

Laboratory hours<br />

6 hours<br />

Lecturer<br />

Dr. M. Farrugia<br />

Prerequisites and exclusions<br />

Leads to<br />

MEC1405 - Thermodynamics I<br />

Objectives This unit <strong>in</strong>troduces the basic concepts <strong>of</strong> thermodynamics,<br />

the laws <strong>of</strong> thermodynamics, and mixtures<br />

Syllabus • Fluid Flow: Flow <strong>of</strong> Gas and Vapour through ducts <strong>of</strong><br />

constant/vary<strong>in</strong>g cross section area; Critical pressure<br />

ratio; Efficiency <strong>of</strong> nozzles and diffusers; Meta-stable<br />

state.<br />

• Combustion: Stoichiometry, products <strong>of</strong> combustion,<br />

calorific value, enthalpy <strong>of</strong> combustion, application <strong>of</strong><br />

the first law to combustion processes, adiabatic flame<br />

temperature, dissociation.<br />

• Air standard Cycles: Carnot Cycle, Otto Cycle, Joule<br />

Cycle, Diesel Cycle, Mixed Combustion Cycle,<br />

Ericsson Cycle, Sterl<strong>in</strong>g Cycle, Open and Closed Gas<br />

Turb<strong>in</strong>e Cycle, Optimization <strong>of</strong> Gas Turb<strong>in</strong>e Cycle,<br />

Cycle with Regenerator, Effects <strong>of</strong> variable specific<br />

heats, Cycle for Jet Propulsion. Air Refrigeration Cycle.<br />

• Vapour cycles: Simple Rank<strong>in</strong>e cycle, Rank<strong>in</strong>e cycle<br />

with re-heat; Regenerative cycle; Back pressure turb<strong>in</strong>e<br />

and extraction turb<strong>in</strong>e cycles; B<strong>in</strong>ary cycle, Comb<strong>in</strong>ed<br />

cycle, Simple vapour compression refrigeration cycle.<br />

Heat pump cycle.<br />

.<br />

• Air Compressors: S<strong>in</strong>gle and double act<strong>in</strong>g mach<strong>in</strong>es;<br />

Effect <strong>of</strong> clearance volume; isothermal, adiabatic and<br />

volumetric efficiency, Multi-stag<strong>in</strong>g and <strong>in</strong>tercool<strong>in</strong>g.<br />

Laboratory work • Gas Turb<strong>in</strong>e or Internal combustion eng<strong>in</strong>e<br />

• Flow <strong>of</strong> gas/vapour through nozzle and diffuser<br />

• Combustion processes<br />

• Air compressor<br />

Assessment 90% written exam<strong>in</strong>ation, 10% practical<br />

Text books and resources • Eastop and McConkey, Applied Thermodynamics for<br />

<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Technologists.<br />

• Rogers & Mayhew, <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Thermodynamics<br />

Work and Heat Transfer<br />

- 10 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC2308 - Mechanics <strong>of</strong> Materials II<br />

Credits 5<br />

Lectures/tutorial hours 22 hours lectures, 3 hours tutorials<br />

Laboratory hours<br />

10 hours<br />

Lecturer<br />

Dr. M. Muscat<br />

Prerequisites and exclusions<br />

Leads to<br />

MEC1401 - Mechanics <strong>of</strong> Materials I<br />

Objectives This unit builds up on the eng<strong>in</strong>eer<strong>in</strong>g applications<br />

encountered <strong>in</strong> Mechanics <strong>of</strong> Materials I. It places an<br />

emphasis on the solution <strong>of</strong> the equilibrium, compatibility <strong>of</strong><br />

deformation and constitutive equations <strong>in</strong> order to solve<br />

certa<strong>in</strong> <strong>in</strong>determ<strong>in</strong>ate problems<br />

Syllabus • Analysis <strong>of</strong> plane stress and plane stra<strong>in</strong> – Equations<br />

for the transformation <strong>of</strong> plane stress and plane stra<strong>in</strong>,<br />

Mohr’s circle for plane stress and plane stra<strong>in</strong>, pr<strong>in</strong>cipal<br />

stresses and pr<strong>in</strong>cipal stra<strong>in</strong>s, electrical resistance stra<strong>in</strong><br />

gauges.<br />

• Theories <strong>of</strong> elastic failure – Maximum shear stress<br />

theory (Tresca), Shear stra<strong>in</strong> energy theory (von<br />

Misses), Maximum pr<strong>in</strong>cipal stress theory.<br />

• Analysis <strong>of</strong> columns – energy methods to calculate<br />

buckl<strong>in</strong>g load.<br />

• Design <strong>of</strong> structural connections – rivets, bolts and<br />

welds.<br />

• Statically <strong>in</strong>determ<strong>in</strong>ate structures and limit<br />

analysis.<br />

• Thick walled cyl<strong>in</strong>ders and rotat<strong>in</strong>g discs.<br />

Laboratory work This will take the form <strong>of</strong> group work and can be either<br />

laboratory work, a computer based project or any other<br />

assignment chosen by the course co-ord<strong>in</strong>ator.<br />

Assessment 80% written exam<strong>in</strong>ation, 20% practical<br />

Text books and resources • Mechanics <strong>of</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Materials, P.P. Benham, R.J.<br />

Crawford, C.G. Armstrong<br />

• Mechanics <strong>of</strong> Materials, E.P. Popov<br />

• Advanced Strength and Applied Elasticity, A.C. Ugural,<br />

S.K. Fenster<br />

- 11 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC2340 – Fluid Mechanics I<br />

Credits 5<br />

Lectures/tutorial hours<br />

Laboratory hours<br />

22 hours lectures, 6 hours tutorials<br />

Lecturer<br />

Dr. T. Sant<br />

Prerequisites and exclusions Prerequisites: Mathematics and Physics ALevel Standard<br />

Leads to MEC2341 - Fluid Mechanics II<br />

Objectives This unit <strong>in</strong>troduces the basic concepts <strong>of</strong> fluid statics and<br />

fluid dynamics relevant to mechanical eng<strong>in</strong>eer<strong>in</strong>g with<br />

emphasis placed on physical understand<strong>in</strong>g.<br />

Syllabus • Fluid basics<br />

Units, dimensional formulae, pressure, shear stress,<br />

viscosity.<br />

Laboratory work • Data analysis<br />

• Fluids at rest<br />

• Fluids <strong>in</strong> motion<br />

• Data analysis<br />

Introduction to basic statistical methods and comb<strong>in</strong><strong>in</strong>g<br />

experimental uncerta<strong>in</strong>ties.<br />

• Fluid statics<br />

Pressure <strong>in</strong> a static fluid, buoyancy, equilibrium, forces<br />

on submerged bodies, stability <strong>of</strong> float<strong>in</strong>g bodies, small<br />

oscillations <strong>of</strong> float<strong>in</strong>g bodies, pressure measurement,<br />

aerostatics.<br />

• Fluid dynamics<br />

Integral relations for a control volume, differential<br />

relations to fluid flow, mass cont<strong>in</strong>uity, Bernoulli<br />

equation, conservation <strong>of</strong> energy, l<strong>in</strong>ear and angular<br />

momentum.<br />

Assessment 75% written exam<strong>in</strong>ation, 25% practical<br />

Text books and resources Fluid Mechanics by Frank M White<br />

- 12 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC2341 – Fluid Mechanics II<br />

Credits 5<br />

Lectures/tutorial hours 22 hours lectures, 6 hours tutorials<br />

Laboratory hours<br />

6 hours<br />

Lecturer<br />

Dr. C. Micallef<br />

Prerequisites and exclusions<br />

Leads to<br />

Prerequisites: MEC2340 – Fluid Mechanics I<br />

Objectives This unit is an <strong>in</strong>termediate module <strong>in</strong> fluid mechanics<br />

applicable to a wide range <strong>of</strong> eng<strong>in</strong>eer<strong>in</strong>g practice.<br />

Syllabus • Dimensional analysis and similarity<br />

Buck<strong>in</strong>gham Pi theorem, similarity, dimensionless<br />

groups, model ship test<strong>in</strong>g.<br />

• Flow <strong>in</strong> ducts<br />

Lam<strong>in</strong>ar and turbulent flow <strong>in</strong> pipes, Darcy equation,<br />

head loss - friction factor, Moody chart, m<strong>in</strong>or losses,<br />

multiple pipe systems, three reservoir problems, non<br />

circular ducts.<br />

• Flow past immersed bodies<br />

Momentum <strong>in</strong>tegral equation, boundary layer<br />

equations, flat-plate boundary layer, boundary layers<br />

with pressure gradient, experimental external flows<br />

<strong>in</strong>clud<strong>in</strong>g drag and lift.<br />

Laboratory work • Dynamic similarity<br />

• Flow <strong>in</strong> ducts<br />

• Flow past immersed bodies<br />

Assessment 75% written exam<strong>in</strong>ation, 25% practical<br />

Text books and resources Fluid Mechanics by Frank M White<br />

- 13 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC2402 – <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Components<br />

Credits 5<br />

Lectures/tutorial hours<br />

Laboratory hours<br />

28 hours<br />

Lecturer<br />

Dr. P. Mollicone<br />

Prerequisites and exclusions MEC2340 - Fluid Mechanics I, MEC2308 - Mechanics <strong>of</strong><br />

Materials and MEC1405 – Thermodynamics I<br />

Leads to<br />

Objectives The module will <strong>in</strong>troduce students to different types <strong>of</strong><br />

components, performance characteristics, <strong>in</strong>clud<strong>in</strong>g how to<br />

read manufacturers’ specs and basic formulae, how to choose<br />

a given component for a given application and how to follow<br />

and use standards such as European codes <strong>of</strong> standards.<br />

Syllabus<br />

Laboratory work<br />

Assessment 100% Assignment<br />

Boilers<br />

Steam turb<strong>in</strong>es and condensors<br />

Calorifiers, Heat exchangers, Cool<strong>in</strong>g towers<br />

Water treatment<br />

Pumps and fans<br />

Refrigeration<br />

HVAC<br />

Hydraulics & Pneumatics<br />

Compressors<br />

Prime movers<br />

Electric motors<br />

Renewable energy components<br />

Electrical components<br />

Gears<br />

Clutches<br />

Belt drives, Cha<strong>in</strong> drives<br />

Flexible jo<strong>in</strong>ts and coupl<strong>in</strong>gs<br />

Bear<strong>in</strong>gs<br />

Lubrication<br />

Fasteners, Keys, Spigots, Spl<strong>in</strong>es<br />

Text books and resources Robert L. Norton – Mach<strong>in</strong>e Design, An <strong>in</strong>tegrated Approach<br />

J.E.Shigley, C.R.Mischke, R.G.Budynas – <strong>Mechanical</strong><br />

<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Design<br />

- 14 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

This unit is <strong>of</strong>fered to the Industrial <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Stream.<br />

Unit Name MEC2403 - Introductory Dynamics<br />

Credits 3<br />

Lectures/tutorial hours<br />

Laboratory hours<br />

16 hours lectures, 4 hours tutorials<br />

Lecturer<br />

Dr. P. Mollicone<br />

Prerequisites and exclusions <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics I<br />

Leads to<br />

Objectives<br />

Syllabus • Basic pr<strong>in</strong>ciples <strong>in</strong> dynamics – Newton’s law,<br />

Momentum, Impulse, D’Alembert’s pr<strong>in</strong>ciple, Work and<br />

Energy<br />

• Dynamics <strong>of</strong> a particle<br />

• Dynamics <strong>of</strong> system <strong>of</strong> particles<br />

• Moment <strong>of</strong> <strong>in</strong>ertia and its transformation, pr<strong>in</strong>cipal axes<br />

and pr<strong>in</strong>cipal moments <strong>of</strong> <strong>in</strong>ertia<br />

• Dynamics <strong>of</strong> rigid body due to – translation, rotation,<br />

general planar motion<br />

Laboratory work<br />

Assessment 100% written exam<strong>in</strong>ation<br />

Text books and resources • Meriam J.L., Kraig L.G., <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics –<br />

Dynamics<br />

• Hibbeler R. C., <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics – Dynamics<br />

- 15 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

This unit is <strong>of</strong>fered to the B.Sc. (Hons.) Degree – Chemistry with Materials<br />

Unit Name MEC2404 - Statics for Scientists<br />

Credits 6<br />

Lectures/tutorial hours<br />

Laboratory hours<br />

28 hours lectures, 14 hours tutorials<br />

Lecturer<br />

Prerequisites and exclusions<br />

Leads to<br />

Dr. Z. Sant<br />

MEC2300 - <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics – K<strong>in</strong>ematics and MEC1401 -<br />

Mechanics <strong>of</strong> Materials 1<br />

Objectives This unit <strong>in</strong>troduces the concept <strong>of</strong> classical mechanics, the<br />

pr<strong>in</strong>ciples <strong>of</strong> model<strong>in</strong>g various loads and solv<strong>in</strong>g equilibrium<br />

between bodies connected by means <strong>of</strong> constra<strong>in</strong>s.<br />

Syllabus • Basic pr<strong>in</strong>ciples <strong>of</strong> Mechanics and Statics<br />

• Force systems and their description<br />

• Equivalence and equilibrium <strong>in</strong> Statics us<strong>in</strong>g vector<br />

algebra.<br />

• Applications <strong>of</strong> pr<strong>in</strong>ciple <strong>of</strong> equivalence - centroid <strong>of</strong><br />

area, centre <strong>of</strong> gravity.<br />

• Solid body constra<strong>in</strong>s and their characteristics<br />

• Equilibrium <strong>of</strong> a constra<strong>in</strong>ed solid body<br />

• System <strong>of</strong> coupled bodies <strong>in</strong> equilibrium. Trusses.<br />

• Friction and its application to mechanisms<br />

Laboratory work Can be either laboratory work, computer based project or any<br />

other assignment chosen by the course co-ord<strong>in</strong>ator<br />

Assessment 80% written exam<strong>in</strong>ation, 20% assignment<br />

Text books and resources • Meriam J.L., Kraig L.G., <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics – Statics<br />

• Hibbeler R. C., <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics – Statics<br />

- 16 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Level 3 units<br />

- 17 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC3007 – Vibration Analysis I<br />

Credits 5<br />

Lectures/tutorial hours<br />

Laboratory hours<br />

28 hours<br />

Lecturer<br />

Dr. D. Camilleri<br />

Prerequisites and exclusions<br />

Leads to MEC3008 - Vibration Analysis II<br />

Objectives An <strong>in</strong>troductory course <strong>in</strong> <strong>Mechanical</strong> Vibration systems<br />

hav<strong>in</strong>g s<strong>in</strong>gle degree <strong>of</strong> freedom. This <strong>in</strong>cludes theory,<br />

computational aspects and applications. An emphasis <strong>of</strong> the<br />

physical significance and <strong>in</strong>terpretation built upon previous<br />

mechanics units shall be made.<br />

Syllabus • Periodic harmonic and non harmonic motion<br />

• Natural frequency <strong>of</strong> s<strong>in</strong>gle degree <strong>of</strong> freedom<br />

systems:<br />

Newton’s second law <strong>of</strong> motion<br />

Energy method<br />

Raleigh’s method<br />

• Damped free vibration <strong>of</strong> s<strong>in</strong>gle degree <strong>of</strong> freedom<br />

systems:<br />

Viscous damp<strong>in</strong>g<br />

Critical damp<strong>in</strong>g, under-damp<strong>in</strong>g and over damp<strong>in</strong>g<br />

Logarithmic decrement<br />

• Forced vibrations <strong>of</strong> viscous damped s<strong>in</strong>gle degree <strong>of</strong><br />

freedom systems:<br />

Harmonic excitation, support excitation and excitation<br />

due to rotat<strong>in</strong>g imbalance<br />

Method <strong>of</strong> complex algebra<br />

Transmissibility and vibration isolation<br />

Vibration measurement <strong>in</strong>struments<br />

• Transient analysis due to impulsive forces<br />

• Transverse vibrations <strong>of</strong> beams:<br />

The energy method and Dunkerley’s method Whirl<strong>in</strong>g <strong>of</strong><br />

shafts<br />

Laboratory work Can be either laboratory work, computer based project or any<br />

other assignment chosen by the course co-ord<strong>in</strong>ator<br />

Assessment 80% written exam<strong>in</strong>ation, 20% practical<br />

Text books and resources • Seto W., <strong>Mechanical</strong> Vibrations<br />

• Thompson W.T. theory <strong>of</strong> Vibrations with Applications<br />

- 18 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC3008 - Vibration Analysis II<br />

Credits 5<br />

Lectures/tutorial hours<br />

Laboratory hours<br />

28 hours lectures<br />

Lecturer<br />

Dr. D. Camilleri<br />

Prerequisites and exclusions MEC3007 - Vibration Analysis I<br />

Leads to<br />

Objectives This module familiarizes students with vibration analysis <strong>of</strong><br />

torsional oscillations, mutli-degree <strong>of</strong> freedom systems and<br />

cont<strong>in</strong>uous media. Numerical methods are established to<br />

identify their dynamic response.<br />

Syllabus • Torsional oscillations:<br />

Two and three rotor systems<br />

Stepped shafts, equivalent lengths and location <strong>of</strong> nodes<br />

Analysis <strong>of</strong> geared systems<br />

• Numerical and matrices methods <strong>of</strong> multi-degree <strong>of</strong><br />

freedom systems:<br />

Analysis <strong>of</strong> free, damped and forced multi-degree <strong>of</strong><br />

freedom systems<br />

Matrix analysis us<strong>in</strong>g the characteristic equation and the<br />

power iterative method<br />

Dynamic stiffness and flexibility matrices<br />

<strong>Mechanical</strong> impedance method<br />

Holzer’s method<br />

Stodola’s method<br />

Branched systems<br />

• Vibrations <strong>of</strong> cont<strong>in</strong>uous media:<br />

Longitud<strong>in</strong>al vibration <strong>of</strong> bars<br />

Transverse vibration <strong>of</strong> beams<br />

The orthogonality pr<strong>in</strong>ciple<br />

Torsional vibrations <strong>of</strong> circular shafts<br />

Laboratory work Can be either laboratory work, computer based project or any<br />

other assignment chosen by the course co-ord<strong>in</strong>ator<br />

Assessment 80% written exam<strong>in</strong>ation, 20% assignment<br />

Text books and resources • Seto W., <strong>Mechanical</strong> Vibrations<br />

• Thompson W.T. theory <strong>of</strong> Vibrations with Applications<br />

- 19 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC3103 – Heat Transfer<br />

Credits 5<br />

Lectures/tutorial hours 22 hours lectures, 6 hours tutorials<br />

Laboratory hours<br />

6 hours<br />

Lecturer<br />

Dr. C. Micallef<br />

Prerequisites and exclusions<br />

Leads to<br />

Prerequisites: MEC2307 - Thermodynamics II and MEC2341<br />

- Fluid Mechanics II<br />

Objectives This unit is an advanced module <strong>in</strong> heat transfer relevant to<br />

mechanical eng<strong>in</strong>eer<strong>in</strong>g with emphasis placed on physical<br />

understand<strong>in</strong>g.<br />

Syllabus • Conduction<br />

Thermal conductivity, thermal resistance networks,<br />

analytical and numerical solutions for one- and twodimensional<br />

steady-state conduction, one-dimensional<br />

transient and unsteady conduction.<br />

• Convection<br />

General concepts and phenomena, velocity and thermal<br />

boundary layers, Reynolds analogy, use <strong>of</strong> experimental<br />

correlations for <strong>in</strong>ternal and external flows, enhancement<br />

techniques for convective heat transfer<br />

• Radiation<br />

Emissivity, absorptivity, transmissivity, Kirchh<strong>of</strong>f's law,<br />

black body radiation heat transfer, view factors, grey<br />

body radiation exchange, radiation networks.<br />

• Boil<strong>in</strong>g and condensation heat transfer<br />

Introduction to boil<strong>in</strong>g and condensation heat transfer<br />

• Heat Exchangers<br />

Laboratory work • Conduction<br />

• Convection<br />

• Radiation<br />

•<br />

Assessment 75% written exam<strong>in</strong>ation, 25% practical<br />

Text books and resources Fundamentals <strong>of</strong> Mass and Heat Transfer by Incropera DeWitt<br />

Heat Transfer by J P Holman<br />

- 20 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC3302 – Eng<strong>in</strong>eer <strong>in</strong> Society<br />

Credits 3<br />

Lectures/tutorial hours 22 hours lectures<br />

Laboratory hours<br />

None<br />

Lecturer<br />

TBA<br />

Prerequisites and exclusions Prerequisites: none<br />

Leads to n/a<br />

Objectives This unit <strong>in</strong>troduces non-eng<strong>in</strong>eer<strong>in</strong>g issues that the<br />

pr<strong>of</strong>essional eng<strong>in</strong>eer has to deal with <strong>in</strong> his pr<strong>of</strong>essional<br />

career.<br />

Syllabus What is a pr<strong>of</strong>ession?<br />

The eng<strong>in</strong>eer<strong>in</strong>g warrant<br />

Pr<strong>of</strong>essional ethics for eng<strong>in</strong>eers<br />

Occupational Health and Safety<br />

Standards (the Malta Standards Authority, CEN, ISO,<br />

etc)<br />

Intellectual Property (patents and copyright)<br />

Industrial relations and employment<br />

Environmental Directives<br />

Authorities, networks and monopolies<br />

Companies and partnerships<br />

Entrepreneurship<br />

Quality Standard 9000<br />

Laboratory work None<br />

Assessment 90% written exam<strong>in</strong>ation, 10% assignment<br />

Text books and resources www.justice.gov.mt for relevant legislation<br />

www.mra.org.mt<br />

www.msa.org.mt<br />

www.ohsa.org.mt<br />

www.mca.org.mt<br />

Humphreys Kenneth K., What every eng<strong>in</strong>eer should<br />

know about ethics, Marcek Dekker Inc., ISBN 0-8247-<br />

8208-9.<br />

- 21 -

Department <strong>of</strong> <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MEC3400 – Environmental <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Credits 5<br />

Lectures/tutorial hours 24 hours lectures<br />

Laboratory hours<br />

4 hours for <strong>in</strong>dustrial visits<br />

Lecturer<br />

Pr<strong>of</strong>. R. Ghirlando<br />

Prerequisites and exclusions none<br />

Leads to n/a<br />

Objectives This unit <strong>in</strong>troduces the basic concepts <strong>of</strong> environmental<br />

eng<strong>in</strong>eer<strong>in</strong>g.<br />

Syllabus Introduction to Environmental <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Susta<strong>in</strong>able development<br />

Air Emissions (sources and control)<br />

Energy and the Environment<br />

Water<br />

Life Cycle Assessment Methodology<br />

Green Design<br />

Cleaner Manufacture<br />

Solid Waste management<br />

Waste m<strong>in</strong>imisation and prevention<br />

Recycl<strong>in</strong>g<br />

Environmental laws and regulations<br />

Environment management systems<br />

Environmental audits<br />

Laboratory work Replaced by visits to recycl<strong>in</strong>g and waste management sites<br />

Assessment 90% written exam<strong>in</strong>ation, 10% assignment<br />

Text books and resources State <strong>of</strong> the Environment Reports for Malta 2002, 2005, 2006.<br />

This and other <strong>in</strong>formation available on www.mepa.org.mt<br />

Masters Gilbert M. and Wendell P.Ela, Environmental<br />

<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> and Science, Prentice Hall, ISBN 0-13-148193-2<br />

- 22 -

Department <strong>of</strong> Industrial and Manufactur<strong>in</strong>g <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Study-units <strong>of</strong>fered by the<br />

Dept. <strong>of</strong> Industrial and Manufactur<strong>in</strong>g Eng.<br />

Faculty <strong>of</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

University <strong>of</strong> Malta<br />

- 1 -

Department <strong>of</strong> Industrial and Manufactur<strong>in</strong>g <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Level 1 units<br />

- 2 -

Department <strong>of</strong> Industrial and Manufactur<strong>in</strong>g <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MFE 1101 - <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Draw<strong>in</strong>g<br />

Credits 5<br />

Lectures/tutorial hours 24 hours lectures, 3 hours tutorials<br />

Laboratory hours Apart from the theoretical aspect, most <strong>of</strong> the lectures <strong>in</strong>clude<br />

hands-on practice on generat<strong>in</strong>g eng<strong>in</strong>eer<strong>in</strong>g draw<strong>in</strong>gs.<br />

Lecturer<br />

Ing. P. Farrugia<br />

Prerequisites and exclusions None<br />

Leads to MFE2103 – Computer-Aided <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Design<br />

MFE3105 – <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Design<br />

Objectives This unit covers the pr<strong>in</strong>ciples and practice <strong>of</strong> eng<strong>in</strong>eer<strong>in</strong>g<br />

draw<strong>in</strong>g. It aims at provid<strong>in</strong>g students with the basics <strong>in</strong><br />

understand<strong>in</strong>g, read<strong>in</strong>g and generat<strong>in</strong>g eng<strong>in</strong>eer<strong>in</strong>g draw<strong>in</strong>gs.<br />

Syllabus<br />

• Introduction to <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Draw<strong>in</strong>g<br />

The importance for eng<strong>in</strong>eers to express their ideas manually<br />

through draw<strong>in</strong>g; types <strong>of</strong> draw<strong>in</strong>gs used <strong>in</strong> the design stages<br />

<strong>of</strong> a technical system; roles <strong>of</strong> Computer-Aided Design<br />

(CAD) systems to produce eng<strong>in</strong>eer<strong>in</strong>g draw<strong>in</strong>gs.<br />

• General <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Draw<strong>in</strong>g Pr<strong>in</strong>ciples<br />

First vs. third angle projections; l<strong>in</strong>ework and letter<strong>in</strong>g;<br />

scales; section views; three-dimensional illustrations (e.g.<br />

isometric projection); geometrical constructions; draw<strong>in</strong>g<br />

standards (e.g. BS8888:2004); draught<strong>in</strong>g conventions<br />

associated with threads, nuts, bolts, screws, spr<strong>in</strong>gs, gears<br />

and bear<strong>in</strong>gs; dimension<strong>in</strong>g pr<strong>in</strong>ciples; general graphical<br />

symbols (e.g. to <strong>in</strong>dicate surface f<strong>in</strong>ish); common<br />

abbreviations.<br />

• Conceptual design draw<strong>in</strong>gs<br />

Importance <strong>of</strong> sketch<strong>in</strong>g; types <strong>of</strong> sketches (rough sketches,<br />

sketches drawn to scale); graphical representations<br />

commonly used <strong>in</strong> sketches (e.g. perspective projection);<br />

sketch<strong>in</strong>g techniques.<br />

• Detailed design draw<strong>in</strong>gs<br />

Draw<strong>in</strong>g layouts (s<strong>in</strong>gle-part draw<strong>in</strong>gs, assembly draw<strong>in</strong>gs);<br />

limits and fits; geometrical toleranc<strong>in</strong>g and datums; specific<br />

graphical symbols used <strong>in</strong> weld<strong>in</strong>g, pneumatics and<br />

electronics.<br />

.<br />

Laboratory work • S<strong>in</strong>ce most <strong>of</strong> the lectures <strong>in</strong>clude hands-on practice,<br />

students are required to br<strong>in</strong>g draw<strong>in</strong>g <strong>in</strong>struments.<br />

Draw<strong>in</strong>g boards will be provided.<br />

Assessment 100% - Assignment<br />

Text books and resources Simmons, C. & Maguire, D. (2004) "Manual <strong>of</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Draw<strong>in</strong>g to British and International Standards", Newnes,<br />

ISBN 0-7506-5120-2.<br />

- 3 -

Department <strong>of</strong> Industrial and Manufactur<strong>in</strong>g <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MFE1202 - Fundamentals <strong>of</strong> Manufactur<strong>in</strong>g & Mach<strong>in</strong><strong>in</strong>g<br />

Credits 5<br />

Lectures/tutorial hours 24 hours lectures, 4 hours tutorials<br />

Laboratory hours<br />

6 hours<br />

Lecturer<br />

Prerequisites and exclusions<br />

Dr. M.A. Saliba<br />

Leads to MFE2201 – Advanced Manufactur<strong>in</strong>g Processes and<br />

MFE2204 – Manufactur<strong>in</strong>g Systems<br />

Objectives This module presents to the students an <strong>in</strong>troduction to the<br />

fundamental pr<strong>in</strong>ciples <strong>of</strong> manufactur<strong>in</strong>g, and a descriptive<br />

and analytical approach to mach<strong>in</strong><strong>in</strong>g technology and<br />

processes.<br />

Syllabus • Manufactur<strong>in</strong>g Fundamentals<br />

• Introduction to Manufactur<strong>in</strong>g Technologies<br />

• Elements <strong>of</strong> Mach<strong>in</strong>e Tool Design<br />

• Tool Geometry and Chip Formation<br />

• Mechanics <strong>of</strong> Cutt<strong>in</strong>g (S<strong>in</strong>gle Po<strong>in</strong>t Tools)<br />

• Cutt<strong>in</strong>g Tool Technology<br />

• Turn<strong>in</strong>g, Drill<strong>in</strong>g and Related Operations<br />

• Mill<strong>in</strong>g Mach<strong>in</strong>e Operations<br />

• Gr<strong>in</strong>d<strong>in</strong>g and other Abrasive Processes<br />

• Broach<strong>in</strong>g, Saw<strong>in</strong>g, Fil<strong>in</strong>g, Shap<strong>in</strong>g and Plan<strong>in</strong>g<br />

• Shape, Tolerance and Surface F<strong>in</strong>ish<br />

• Selection <strong>of</strong> Cutt<strong>in</strong>g Conditions<br />

Laboratory work • Tangential Force on a Lathe Tool<br />

• Gr<strong>in</strong>d<strong>in</strong>g Demonstration<br />

Assessment 80% written exam<strong>in</strong>ation, 20% practical<br />

Text books and resources Black S.C., Chiles V., Lissaman A.J., Mart<strong>in</strong> S.J., “Pr<strong>in</strong>ciples<br />

<strong>of</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Manufacture”, Arnold, 1996.<br />

Groover M. P., “Fundamentals <strong>of</strong> Modern Manufactur<strong>in</strong>g”,<br />

2nd edition, John Wiley and Sons, 2002<br />

- 4 -

Department <strong>of</strong> Industrial and Manufactur<strong>in</strong>g <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Level 2 units<br />

- 5 -

Department <strong>of</strong> Industrial and Manufactur<strong>in</strong>g <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MFE2101 - <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Metrology<br />

Credits 5<br />

Lectures/tutorial hours 26 hours lectures, 4 hours tutorials<br />

Laboratory hours<br />

6 hours<br />

Lecturer<br />

Ing. Tania Briffa<br />

Prerequisites and exclusions /<br />

Leads to /<br />

Objectives This unit <strong>in</strong>troduces the students to the idea <strong>of</strong> standards and<br />

standardizations, and to gaug<strong>in</strong>g and measurement<br />

applications.<br />

Syllabus • Measurement and gaug<strong>in</strong>g. Use and care <strong>of</strong> various<br />

measur<strong>in</strong>g and gaug<strong>in</strong>g <strong>in</strong>struments. Angular and taper<br />

measurement. Use <strong>of</strong> s<strong>in</strong>ebar, precision levels, and angle<br />

gauges. The pr<strong>in</strong>ciple <strong>of</strong> the Angle Dekkor and<br />

autocollimator. The rotary table and divid<strong>in</strong>g head.<br />

Precision polygon. Methods <strong>of</strong> taper angle measurement.<br />

Use <strong>of</strong> telescopic and hole gauges. Flatness, straightness<br />

and roundness measurement.<br />

• Sources <strong>of</strong> errors <strong>in</strong> l<strong>in</strong>ear measurement.<br />

• Design <strong>of</strong> limit gauges.<br />

• General <strong>in</strong>spection equipment - The reference surface,<br />

surface table and surface plates. Toolmakers’ flat.<br />

Straight edges. Mean true plane <strong>of</strong> a surface plate. Right<br />

angle and box angle plate. Eng<strong>in</strong>eers’ square. Eng<strong>in</strong>eers’<br />

parallel. Vee and ‘B’ blocks. Use <strong>of</strong> calibrated balls,<br />

rollers and p<strong>in</strong>s. Taper parallel.<br />

• Use <strong>of</strong> optics <strong>in</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Metrology.<br />

• Comparators.<br />

• Thread measurement.<br />

• Emerg<strong>in</strong>g trends – Micro and Nano metrology.<br />

Laboratory work • Dimensional Measurement Exercises<br />

Assessment 80% written exam<strong>in</strong>ation, 20% project<br />

Text books and resources • Shotbolt & Galyer, Metrology for Eng<strong>in</strong>eers, ISBN<br />

03043 18442.<br />

• Lissman, Pr<strong>in</strong>ciples <strong>of</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Production, ISBN<br />

03400 48530.<br />

• Wilken<strong>in</strong>g & Koenders, Nanoscale Calibration Standards<br />

and Methods, ISBN 3-527-40502-X<br />

- 6 -

Department <strong>of</strong> Industrial and Manufactur<strong>in</strong>g <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MFE 2103 – Computer-Aided <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Design<br />

Credits 5<br />

Lectures/tutorial hours 14 hours lectures<br />

Laboratory hours<br />

12 hours<br />

Lecturers<br />

Dr. J.C. Borg, Ing. P. Farrugia<br />

Prerequisites and exclusions MFE1101 – <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Draw<strong>in</strong>g<br />

Leads to MFE3105– <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Design<br />

Objectives<br />

By the end <strong>of</strong> this module, students will acquire knowledge<br />

on the pr<strong>in</strong>ciples <strong>of</strong> Computer Aided <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Design for<br />

a range <strong>of</strong> sectors <strong>in</strong>clud<strong>in</strong>g <strong>Mechanical</strong> and Manufactur<strong>in</strong>g.<br />

This knowledge transfer will be achieved through a structured<br />

mix <strong>of</strong> theory and practice.<br />

Lectures: • Introduction to CAED; The role <strong>of</strong> C.A.E.D. <strong>in</strong> the<br />

Design Process & In Industry;<br />

• Computer Hardware; Typical hardware configurations for<br />

C.A.E.D. applications.<br />

• Computer S<strong>of</strong>tware for C.A.D.; Model representations:<br />

2D, 3D, wire-frame, surface and solid models (CSG & B-<br />

REP);<br />

• Product Modell<strong>in</strong>g us<strong>in</strong>g C.A.D.; Entity Manipulation;<br />

Feature-based and Parametric model<strong>in</strong>g;<br />

• 3D Model data standards - GKS, I.G.E.S, STEP/PDES,<br />

DXF, VRML, STL.<br />

• Pr<strong>in</strong>ciples <strong>of</strong> Render<strong>in</strong>g techniques;<br />

• Virtual & Augmented Reality (VR/AR) Systems;<br />

• Knowledge Intensive C.A.D; Product Life Cycle Modell<strong>in</strong>g<br />

(PLM) Systems;<br />

• CAD simulation <strong>of</strong> mechanisms; CAD & Rapid<br />

Prototyp<strong>in</strong>g.<br />

• Synchronous/Asynchronous Collaborative Design Tools.<br />

Practical Sessions<br />

Practical sessions us<strong>in</strong>g a commercial C.A.E.D. system will be<br />

used <strong>in</strong> six sessions <strong>of</strong> 2hrs each, allow<strong>in</strong>g students to acquire<br />

hands-on experience on:<br />

• 2D Geometric Model<strong>in</strong>g;<br />

• 3D Surface & Solid model<strong>in</strong>g;<br />

• Generation <strong>of</strong> Detail Design Draw<strong>in</strong>gs from 3D models;<br />

• CAD Model Data Exchange;<br />

Assessment 50% Project, 50% Lab-based exam<br />

Text books and resources • MCMahon C. & Browne: CADCAM From Pr<strong>in</strong>ciples to<br />

Practice, ISBN 020156021.<br />

• Rooney Joe & Steadman P., Pr<strong>in</strong>ciples <strong>of</strong> Computer Aided<br />

Design, Pitman/Open University, ISBN 0273 026720.<br />

- 7 -

Department <strong>of</strong> Industrial and Manufactur<strong>in</strong>g <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

This unit is <strong>of</strong>fered only to the <strong>Mechanical</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MFE 2105 – <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Design Methods<br />

Credits 2<br />

Lectures/tutorial hours 26 hours lectures<br />

Practical hours<br />

14 hours <strong>of</strong> design project<br />

Lecturers<br />

Dr.J.C. Borg, Ing. P. Farrugia<br />

Prerequisites and exclusions MFE1101 – <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Draw<strong>in</strong>g<br />

MFE 2103 – Computer Aided <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Design<br />

Leads to F<strong>in</strong>al Year Project<br />

Objectives This module <strong>in</strong>troduces students to systematic design<br />

methodologies. The aim is to provide students with a<br />

scientific basis for eng<strong>in</strong>eer<strong>in</strong>g design methodology to enable<br />

them to systematically create solutions to eng<strong>in</strong>eer<strong>in</strong>g<br />

problems.<br />

Semester 1 / Lectures<br />

Assessment 100% Assignment<br />

Text books and resources<br />

• Artefact Theories; Theory <strong>of</strong> Technical systems;<br />

• Design Process Model; Design Theory;<br />

• Design Problem Analysis, Synthesis, Solution Analysis,<br />

Evaluation;<br />

• QFD, PDS, Morphological charts ; SCAMPER, FMEA;<br />

• Design For X Methodologies - Design for Manufacture &<br />

Assembly; Design for the Environment;<br />

• Manag<strong>in</strong>g/Co-ord<strong>in</strong>at<strong>in</strong>g Design Projects,<br />

• Manag<strong>in</strong>g Product Variety and Commonality. Design <strong>of</strong><br />

Product Platforms;<br />

• Mach<strong>in</strong>e Design Elements Selection (eg bear<strong>in</strong>gs, gears,<br />

belts, etc.)<br />

• Design <strong>in</strong> Industry;<br />

• Roozenburg N.F.M & Eekels J., Product Design:<br />

Fundamentals and Methods<br />

JohnWiley&SonsLtd,Wiltshire,1995.<br />

• Pahl G. & Beitz W., <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Design - A Systematic<br />

Approach 2nd edition, Spr<strong>in</strong>ger-Verlag, London, 1996.<br />

- 8 -

Department <strong>of</strong> Industrial and Manufactur<strong>in</strong>g <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MFE2201 – Advanced Manufactur<strong>in</strong>g Processes<br />

Credits 5<br />

Lectures/tutorial hours 24 hours lectures, 4 hours tutorials<br />

Laboratory hours<br />

6 hours<br />

Lecturer<br />

Ing. Pierre Vella<br />

Prerequisites and exclusions<br />

Leads to<br />

MFE1202 – Fundamentals <strong>of</strong> Manufactur<strong>in</strong>g & Mach<strong>in</strong><strong>in</strong>g<br />

Objectives This module is primarily aimed to <strong>in</strong>troduce students to<br />

modern advanced manufactur<strong>in</strong>g processes, which are<br />

<strong>in</strong>creas<strong>in</strong>gly f<strong>in</strong>d<strong>in</strong>g new applications <strong>in</strong> <strong>in</strong>dustry for the<br />

development <strong>of</strong> new products and devices. The students will<br />

also be given an overview <strong>of</strong> Computer Numerical Controlled<br />

(CNC) Mach<strong>in</strong><strong>in</strong>g and part programm<strong>in</strong>g.<br />

Syllabus • CNC Mach<strong>in</strong><strong>in</strong>g and Part Programm<strong>in</strong>g.<br />

• Limitations <strong>of</strong> conventional processes. Introduction to<br />

non-conventional processes.<br />

• Thermal processes <strong>in</strong>clud<strong>in</strong>g Electro Discharge<br />

Mach<strong>in</strong><strong>in</strong>g (spark erosion), Electron Beam Mach<strong>in</strong><strong>in</strong>g,<br />

Plasma Arc Mach<strong>in</strong><strong>in</strong>g, Laser Beam Mach<strong>in</strong><strong>in</strong>g.<br />

• Chemical processes such as Electrochemical mach<strong>in</strong><strong>in</strong>g<br />

(ECM), Photo Chemical Mach<strong>in</strong><strong>in</strong>g, Chemical<br />

Mach<strong>in</strong><strong>in</strong>g.<br />

• <strong>Mechanical</strong> processes such as Ultrasonic Mach<strong>in</strong><strong>in</strong>g,<br />

Abrasive Flow Mach<strong>in</strong><strong>in</strong>g, Abrasive Jet Mach<strong>in</strong><strong>in</strong>g.<br />

• Areas <strong>of</strong> application <strong>of</strong> non-conventional mach<strong>in</strong><strong>in</strong>g.<br />

• Rapid Manufactur<strong>in</strong>g (RM) and Rapid Tool<strong>in</strong>g (RT).<br />

• Manufactur<strong>in</strong>g <strong>in</strong> Electronics<br />

• Micro and nano mach<strong>in</strong><strong>in</strong>g.<br />

• Manufactur<strong>in</strong>g Processes at the micro and nano scales.<br />

Laboratory work These lectures will be supplemented by a series <strong>of</strong> practical<br />

exercises <strong>in</strong> the laboratory as detailed below. An assignment<br />

will be given to the students later <strong>in</strong> the course.<br />

• CNC Mach<strong>in</strong><strong>in</strong>g us<strong>in</strong>g the C<strong>in</strong>c<strong>in</strong>nati VMC<br />

• EDM us<strong>in</strong>g the Dieter Hansen<br />

Assessment 80% written exam<strong>in</strong>ation, 20% practical<br />

Text books and resources Kalpakjian, S. & Schmid S.R., Manufactur<strong>in</strong>g Processes for<br />

<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Materials, 4th Edition, Prentice Hall, 2003, ISBN<br />

0-13-140871-9.<br />

- 9 -

Department <strong>of</strong> Industrial and Manufactur<strong>in</strong>g <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MFE2204 - Manufactur<strong>in</strong>g Systems<br />

Credits 5<br />

Lectures/tutorial hours<br />

Laboratory hours<br />

31 hours lectures, 4 hours tutorials<br />

Lecturer<br />

Dr. C. Pace<br />

Prerequisites and exclusions MFE1202 – Fundamentals <strong>of</strong> Manufactur<strong>in</strong>g & Mach<strong>in</strong><strong>in</strong>g<br />

Leads to<br />

Objectives The objective <strong>of</strong> the module is to give students an<br />

<strong>in</strong>troductory overview and awareness <strong>of</strong> the characteristics <strong>of</strong><br />

manufactur<strong>in</strong>g systems, from the pr<strong>in</strong>ciple subdivisions <strong>in</strong> the<br />

activities with<strong>in</strong> a manufactur<strong>in</strong>g system to the technologies<br />

applied with<strong>in</strong> manufactur<strong>in</strong>g systems. Students will also be<br />

<strong>in</strong>troduced to Lean Manufactur<strong>in</strong>g<br />

Syllabus • An Introduction to Manufactur<strong>in</strong>g - the economic<br />

importance <strong>of</strong> manufactur<strong>in</strong>g, manufactur<strong>in</strong>g sectors,<br />

manufactur<strong>in</strong>g activities;<br />

• Manufactur<strong>in</strong>g Activities : fabrication, assembly, test<strong>in</strong>g<br />

and material transfer, Resources <strong>of</strong> production,<br />

eng<strong>in</strong>eer<strong>in</strong>g <strong>in</strong> manufactur<strong>in</strong>g <strong>in</strong>dustries - product design,<br />

R&D, materials and process eng<strong>in</strong>eer<strong>in</strong>g, manufactur<strong>in</strong>g<br />

eng<strong>in</strong>eer<strong>in</strong>g, <strong>in</strong>dustrial eng<strong>in</strong>eer<strong>in</strong>g, quality eng<strong>in</strong>eer<strong>in</strong>g,<br />

control eng<strong>in</strong>eer<strong>in</strong>g.<br />

• Production System Types and Production Layouts – The<br />

importance <strong>of</strong> material flow considerations; job, batch,<br />

cellular/GT and flow production, layout types; process,<br />

product, cellular. Pr<strong>in</strong>ciples <strong>of</strong> Layout Plann<strong>in</strong>g.<br />

• Plann<strong>in</strong>g Activities <strong>in</strong> Manufactur<strong>in</strong>g Systems: Process<br />

Plann<strong>in</strong>g, l<strong>in</strong>e balanc<strong>in</strong>g <strong>in</strong> flow l<strong>in</strong>es, Production Plann<strong>in</strong>g<br />

: Capacity Plann<strong>in</strong>g, Plann<strong>in</strong>g <strong>of</strong> resources.<br />

• The role <strong>of</strong> technology <strong>in</strong> Manufactur<strong>in</strong>g Systems :<br />

production technologies; automated production systems,<br />

flexible manufactur<strong>in</strong>g systems, plann<strong>in</strong>g and control<br />

technologies; manufactur<strong>in</strong>g execution systems.<br />

• Introduction to Lean Manufactur<strong>in</strong>g.<br />

Laboratory work •<br />

Assessment 80% written exam<strong>in</strong>ation, 20% assignment<br />

Text books and resources Groover M.P., 2001. Automation, Production Systems, and<br />

Computer-Integrated Manufactur<strong>in</strong>g, Prentice Hall.<br />

Haslehurst M., 1981. Manufactur<strong>in</strong>g Technology, 3rd edition,<br />

Edward Arnold.<br />

- 10 -

Department <strong>of</strong> Industrial and Manufactur<strong>in</strong>g <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Level 3 units<br />

- 11 -

Department <strong>of</strong> Industrial and Manufactur<strong>in</strong>g <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong><br />

Unit Name MFE3102 - Mechatronics Systems Design<br />

Credits 5<br />

Lectures/tutorial hours 29 hours lectures<br />

Laboratory hours<br />

6 hours<br />

Lecturer<br />

Dr. C. Pace<br />

Prerequisites and exclusions SCE2210 - Introduction to Control Systems<br />

Aim The aim <strong>of</strong> this module is to provide students with an<br />

understand<strong>in</strong>g <strong>of</strong> the pr<strong>in</strong>ciples <strong>of</strong> Mechatronics <strong>in</strong> product<br />

and process development. The focus will be on the need for<br />

<strong>in</strong>tegrat<strong>in</strong>g diverse technologies <strong>in</strong> develop<strong>in</strong>g successful<br />

systems that satisfy customer requirements.<br />

Objectives At the end <strong>of</strong> the module the students should be able to:<br />

1. Understand the significance <strong>of</strong> <strong>in</strong>tegrat<strong>in</strong>g electronic and<br />

microprocessor based systems <strong>in</strong> mechanical products and<br />

processes;<br />

2. Appreciate the complexity that arises from develop<strong>in</strong>g<br />

such systems and what the system development<br />

requirements are;<br />

3. Comprehend which technologies are <strong>in</strong>volved <strong>in</strong> such<br />

systems and understand the pr<strong>in</strong>ciples <strong>in</strong>volved <strong>in</strong> the<br />

<strong>in</strong>tegration <strong>of</strong> these technologies;<br />

4. Appreciate the role <strong>of</strong> system model<strong>in</strong>g and the pr<strong>in</strong>ciples<br />

<strong>in</strong>volved <strong>in</strong> the analysis and development <strong>of</strong> Mechatronic<br />

systems;<br />

5. Comprehend aspects <strong>of</strong> the design approach relevant to<br />

Mechatronic product and process development.<br />

Syllabus 1. What is Mechatronics? - Microprocessors <strong>in</strong> modern<br />