In this issue - Artist Blacksmiths Association South Australia

In this issue - Artist Blacksmiths Association South Australia In this issue - Artist Blacksmiths Association South Australia

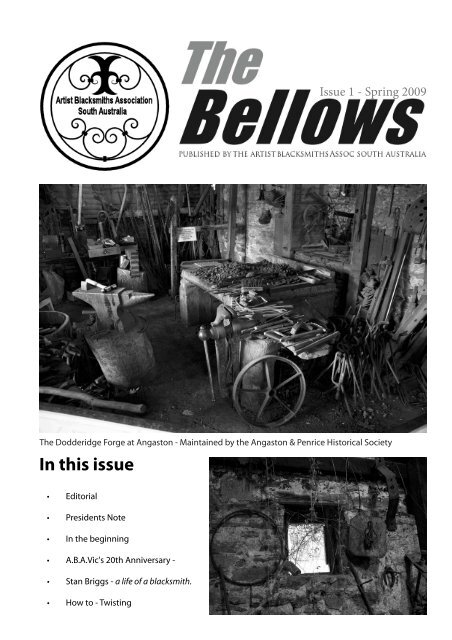

Issue 1 - Spring 2009 The Dodderidge Forge at Angaston - Maintained by the Angaston & Penrice Historical Society In this issue • Editorial • Presidents Note • In the beginning • A.B.A.Vic's 20th Anniversary - • Stan Briggs - a life of a blacksmith. • How to - Twisting

- Page 2 and 3: The Bellows SPRING EDITION OCTOBER

- Page 4 and 5: Presidents Note... Over the past fo

- Page 6 and 7: AUSTRALIAN BLACKSMITHS ASSOCIATION

- Page 8 and 9: GALLERY HIGHLIGHTS FROM THE ABAVic

- Page 10 and 11: As you can imagine, there was plent

- Page 12 and 13: How To............. TWISTING Twisti

Issue 1 - Spring 2009<br />

The Dodderidge Forge at Angaston - Maintained by the Angaston & Penrice Historical Society<br />

<strong>In</strong> <strong>this</strong> <strong>issue</strong><br />

• Editorial<br />

• Presidents Note<br />

• <strong>In</strong> the beginning<br />

• A.B.A.Vic's 20th Anniversary -<br />

• Stan Briggs - a life of a blacksmith.<br />

• How to - Twisting

The Bellows<br />

SPRING EDITION<br />

OCTOBER 2009<br />

EDITOR<br />

Rob Kenning<br />

(08) 83702137<br />

GRAPHIC DESIGN<br />

Rob Kenning<br />

COMMITTEE MEMBERS<br />

PRESIDENT<br />

Chris Carter<br />

(08) 82625415<br />

VICE PRESIDENT<br />

Sonja Hurst<br />

(08) 83860910<br />

SECRETARY<br />

Rob Kenning<br />

TREASURER<br />

Kirstie Stewart<br />

(08) 83779360<br />

GENERAL COMMITTEE<br />

Terry Johnson<br />

(08) 83825559<br />

Cat Lambert<br />

(08) 81650918<br />

Keren Sutcliffe<br />

(08) 82401363<br />

Stan Briggs<br />

(08) 83568868<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

12<br />

13<br />

Contents<br />

......Cover<br />

......Contents<br />

......Editorial<br />

......Presidents Note<br />

......'the beginnings'<br />

......A.B.A.Vic's 20th Anniversary<br />

......20th Anniversary Highlights<br />

......A.B.A.Vic Art Gallery<br />

......Stan Briggs..'a life of a blacksmith'<br />

......How to...TWISTING<br />

......Useful sites and Contacts<br />

Purposes & Objectives of ABASA <strong>In</strong>c<br />

The objectives of the <strong>Association</strong> shall be to promote, preserve, and develop the Craftsmanship,<br />

and techniques of all the various disciplines associated with <strong>Artist</strong>ic Blacksmithing to the<br />

highest standards possible. Supporting these aims include:<br />

a) To Provide means of communication between mature people with an interest in<br />

the craft of Blacksmithing, for the exchange of ideas, experience, techniques and<br />

information for their mutual bene�t, by the publication of a regular Newsletter.<br />

b) To Encourage a greater awareness of, and interest in the appreciation of the skills<br />

of Blacksmithing among Architects, <strong>In</strong>terior Designers, Art and Craft groups, and<br />

the general public, and to provide links between <strong>Blacksmiths</strong> and potential<br />

customers by means of Exhibitions, Demonstrations, and Publications.<br />

c) To Promote and actively provide the opportunity for training in all the various<br />

aspects of Blacksmithing means of demonstrations, lectures, and special tuition<br />

sessions.<br />

d) To Act as a representative body, in the interests of <strong>Australia</strong>n <strong>Blacksmiths</strong>, locally,<br />

nationally and internationally.<br />

e) To Undertake community service, providing these services are within the<br />

comfortable limits of time, talents and costs that the association and individual<br />

members can a�ord, in the context of the associations, purpose, objectives, rules<br />

and legal obligations<br />

f) To encourage communication and goodwill among <strong>Blacksmiths</strong> of all Nations.<br />

g) To co-operate with similar associations in every practical way at the local, national<br />

and international level with the interests of the association’s members and<br />

community<br />

h) To ensure the association achieves the purpose and objectives by all<br />

possible legal means.<br />

Page 2

Editorial<br />

Welcome to our �rst edition of The Bellows Newsletter.<br />

The last few months have been anything but slow during the formation of our new association.<br />

There has been an over whelming interest in the creation of an <strong>Artist</strong>ic <strong>Association</strong> from<br />

blacksmiths all across <strong>South</strong> <strong>Australia</strong> and interstate.<br />

The idea of creating an association in <strong>South</strong> <strong>Australia</strong> was born out of necessity. There are a large<br />

number of smiths in the state that have no representative body or outlet to meet or communicate<br />

with other members of the trade. We had the idea of starting a guild or association, after meeting<br />

with metal smiths, knife makers and artist blacksmiths at various functions and shows over the last<br />

3 years. Another factor considered, was the prickly subject of Public <strong>In</strong>demnity <strong>In</strong>surance.<br />

To secure insurance on an individual basis, was an expensive proposition, especially for those of us<br />

who are practising and learning the craft. We have had o�ers of fee free premises to set up a forge,<br />

only to be ham strung on the insurance side of the deal.<br />

The association of artist blacksmiths will have the facility available to our members for full<br />

insurance for all committee approved events, allowing us to spread out and educate the public on<br />

the many and varied facets of our craft.<br />

Our front cover photo depicts the front facing forge area of the Doddridge Forge in Angaston. Our<br />

good friends at the Angaston & Penrice Society have been managing the forge for many years and<br />

have kept it in the same condition as if Hardy Doddridge had just retired. It still has hand bellows on<br />

the two forges. You can close your eyes and imagine your back in the 1900's. The only thing missing<br />

is the sound of horses in the main street. A days work forging with bellows guarantees a good<br />

nights sleep.<br />

The Doddridge Forge allows us a great opportunity to show the public some of the aspects of the<br />

craft of blacksmithing.<br />

Our newsletter will be our communication outlet at <strong>this</strong> stage, and hopefully, a web site can be<br />

developed down the track. Our key for success will be in gaining input for subject matter from all of<br />

our members in the coming <strong>issue</strong>s. I hope the format of the newsletter sits well for everyone. This is<br />

my �rst try at Desktop Publishing, so any hints and tips from more experienced members and<br />

friends, will be greatly appreciated. It is hoped that the newsletter can be produced as a PDF<br />

document, as most members have computers. For those members who don't, I will endeavour to<br />

produce a hard copy via my local laser printing house in Blackwood.<br />

Our interstate associations in Victoria and New <strong>South</strong> Wales have very high quality publications,<br />

with very interesting content, and I plan to attain that level of quality over the next few <strong>issue</strong>s.<br />

From my point of view, I believe the quality of the content is the major point to strive for, so having<br />

a good balance of articles will be a good starting point. We will have a broad section of talented<br />

members to draw on, whose life, loves and passions, will create interesting reading for everyone.<br />

I'd like to thank the members of ABA Vic and ABA N.S.W. for their support and encouragement for<br />

<strong>this</strong> newsletter, especially Amanda Gibson and Graham Moyses.<br />

Thanks also go to Stan Briggs, for his very interseting article on his working career as a blacksmith.<br />

I trust you will enjoy <strong>this</strong> <strong>issue</strong> as much as I have in putting it together.<br />

Rob Kenning, Editor<br />

Page 3

Presidents Note...<br />

Over the past four months we have seen<br />

the emergence of our <strong>Association</strong> take o�<br />

at a rapid rate.<br />

I would say that it has far surpassed any<br />

thing that we could have imagined. There<br />

is already emerging a strong bond of like<br />

minded people who want to see that <strong>this</strong><br />

�ne craft is kept alive and that the general<br />

public are made aware that it still lives on.<br />

The support that we have already had<br />

from the <strong>Association</strong>s in Victoria and New<br />

<strong>South</strong> Wales has been a valued<br />

encouragement to us all. With the advise<br />

that we have had from them we hope that<br />

we will not have too many hiccups along<br />

the way.<br />

It has been pleasing to see people accept<br />

positions and take responsibilities as<br />

committee members, <strong>this</strong> makes the<br />

sharing of the load much easier.<br />

One our �rst challenges is to �nd a<br />

suitable location where we can establish a<br />

home base.<br />

I am con�dent that we will �nd such a<br />

location just based on the way things have<br />

been happening for us. It has been<br />

amazing that as we set our focus on an<br />

<strong>issue</strong> a solution is o�ered from some one.<br />

The networking with others has certainly<br />

come into play. It is great to see something<br />

that was only a dream three years ago<br />

�nally come to fruition. I look forward to<br />

the future with excited enthusiasm as we<br />

all watch and participate in our new<br />

<strong>Association</strong>. We are lucky to have been<br />

able to secure a<br />

meeting place, courtesy of the Elephant<br />

and Castle Hotel.<br />

Take Care,<br />

Chris Carter.<br />

President<br />

A.B.A.S.A<br />

Page 4

the beginnings................<br />

THE CREATION OF A.B.A.S.A. <strong>In</strong>c<br />

<strong>In</strong> 2006, a class of fourteen began studying a<br />

Certi�cate III in Visual Arts and Contemporary<br />

Craft (<strong>Artist</strong>ic Blacksmithing) at Panorama TAFE<br />

in <strong>South</strong> <strong>Australia</strong>. The course was to be the<br />

�rst of a series of courses o�ered at Panorama<br />

and had the aim of training artist blacksmiths<br />

and promoting their ancient skills. Subjects<br />

covered included Hand Forging, Hammer<br />

Forging, Sculpture, Technical drawing, Manual<br />

and Gas metal Arc welding, Conceptual design<br />

and Communication and Occupational Health<br />

and Safety.<br />

As we approached the end of the course, we<br />

learned that we were to be the only graduates,<br />

as <strong>Artist</strong>ic Blacksmithing would not be o�ered<br />

the following year and the forge at Panorama<br />

TAFE would be closed. It was around <strong>this</strong> time<br />

that the idea of forming a formal group was<br />

seriously discussed. After completing the<br />

course, we kept in touch with each other and<br />

sometimes met for a hit and a chat, but no<br />

further progress on forming our own<br />

association was made. A number of us joined<br />

the <strong>South</strong> <strong>Australia</strong>n Farriers and <strong>Blacksmiths</strong><br />

<strong>Association</strong>, but found that the emphasis was<br />

on horses and farrier work rather that<br />

decorative or artistic blacksmithing.<br />

Around the same time, a small team of artist<br />

smiths demonstrating at the Dodderidge<br />

Forge at Angaston realised that the public<br />

perception of what artistic blacksmithing<br />

entailed varied from “I thought it was a dead<br />

trade” comments to “do you make horse<br />

shoes?”. These circumstances became the<br />

catalyst in our forming the <strong>Artist</strong>ic <strong>Blacksmiths</strong><br />

<strong>Association</strong> of <strong>South</strong> <strong>Australia</strong>. We see it as a<br />

way of supporting each other in our work,<br />

making contact with more experienced<br />

blacksmiths and promoting blacksmithing in<br />

<strong>South</strong> <strong>Australia</strong>.<br />

Contact was made with our immediate<br />

colleagues and then amongst those other <strong>Artist</strong><br />

<strong>Blacksmiths</strong> we could �nd. There seemed to be a<br />

desire of many to have an association that could<br />

cater speci�cally to the requirements of the art<br />

of blacksmithing. Those interested included<br />

professionals, retired smiths, amateurs, hobby<br />

blacksmiths and the younger generation, all<br />

wanting the same thing, - to be involved and<br />

participate in the ancient art of blacksmithing.<br />

With advice and encouragement from the New<br />

<strong>South</strong> Wales and Victorian associations, we<br />

began the process of developing a constitution<br />

and list of aims for the association. A name was<br />

struck, a constitution loosely formed and our<br />

�rst meeting was held in July.<br />

Our association is already growing! Our<br />

inaugural meeting had 7 members present, the<br />

following meeting had 9 members present with<br />

4 apologies. Our recent September meeting had<br />

14 members and 4 apologies. At <strong>this</strong> time, we<br />

have a solid constitution, a logo and name for<br />

our newsletter. We are aiming to establish a<br />

residence as soon as possible and conduct<br />

training, demonstrations and workshops for the<br />

bene�t of our members and visitors.<br />

The beginning of something new is an exciting<br />

time for all involved and we look forward to the<br />

future and development of our association, and<br />

to working with our colleagues interstate.<br />

Written by Rob Kenning and Kirstie Stewart<br />

Page 5

AUSTRALIAN BLACKSMITHS ASSOCIATION Vic<br />

20th Anniversary By Rob Kenning<br />

After �nding out about the 20th Celebrations<br />

over in Victoria from conversations with<br />

Amanda Gibson, we decided to make the<br />

journey to Mt Martha to attend.<br />

Our SA association was in it's infancy and it<br />

provided a good opportunity to pay a visit and<br />

meet some of our fellow artisans and<br />

introduce ourselves.<br />

We made the bookings for accomodation and<br />

left on a wednesday morning.<br />

Prior to us leaving, Terry Johnson and his wife<br />

Margaret, Kirstie Stewart, Sonja Hurst planned<br />

to come over as well. So, we had 5 members<br />

from our association on the road to Victoria.<br />

Gabe Bullock was already over in Victoria and<br />

would meet up with us on the weekend.<br />

We arrived in Mt Martha in the evening and<br />

booked in to our accomodation. The following<br />

morning we made our way down to the Briars<br />

Park venue and introduced ourselves to<br />

Amanda Gibson.<br />

Amanda was preparing to give a lecture in the<br />

principals and history of her association to<br />

groups of visting school children.<br />

We sat in on her �rst lecture and were very<br />

impressed with the coverage and detail she<br />

provided in her presentation.<br />

After the presentation, we made our way up<br />

the hill to the blacksmith venue to meet up<br />

with the organisers, who were very busy<br />

setting up the venue in readiness for the<br />

weekend.<br />

Our �rst port of call was the Gallery of artistic<br />

work being set up by Paul Mills and his<br />

colleagues. There was a wonderful display of<br />

beautiful wrought iron work on display with<br />

the promise of more items to come in the<br />

following hours. When complete, there was 64<br />

exhibits from 16 artists.<br />

The project theme for the weekend was to<br />

construct a garden gate. There were a few<br />

groups of members working on the<br />

designated elements in the design. The plan<br />

was to have the gate built and auctioned o�<br />

on the Sunday afternoon. Unfortunately, for<br />

various reasons, time ran out for the �nal<br />

assembly, even though all of the forging was<br />

completed.<br />

Over the weekend, the crowds ebbed and<br />

�owed. The wintery weather most likely sti�ed<br />

the crowd numbers, but the interest<br />

generated was quite substantial. I am sure the<br />

Victorian association gained a lot of exposure<br />

and a few new members to bolster their ranks.<br />

I know that we all came away very impressed<br />

with the quality of work and professionalism<br />

shown in the organisation.<br />

Aside from ourselves, there was a number of<br />

N.S.W members there to help out and we<br />

managed to meet most of the men and<br />

women instrumental in the formation of both<br />

eastern states associations.<br />

Malcolm Paine, from WA was also there to<br />

tutor and demonstrate his extensive talents at<br />

the anvil. Kirstie was lucky enough to gain<br />

some experience in forge welding, and did<br />

herself proud on her �rst attempt.<br />

Saturday night saw us attend a dinner at<br />

'Josephines' restaurant. Michael Dunn, the<br />

secretary of A.B.A.Vic was the master of<br />

ceremonies and provided an opening speech<br />

followed by the induction of Keith Towe as<br />

Patron to the association.<br />

On Sunday, the forges ran hot and furious as<br />

the smiths completed the last of the forging<br />

for the gate. The auction managed to raise<br />

$1,500.00 for the association.<br />

Sadly, it came to an end and we said our<br />

goodbyes over a few drinks at the gallery.<br />

All in all, it was a fantastic weekend and we all<br />

came away inspired.<br />

Page 6

HIGHLIGHTS FROM THE ABAVic 20th CELEBRATIONS<br />

Members from ABASA at the gallery.<br />

Forged bowls by Paul Mills.<br />

Ray Gard educating the crowd (Gate pattern on Left wall).<br />

Don Marshall working on the project Garden Gate.<br />

A collection of leaves for the "Tree of Life" project. Kirstie Stewart trying out at forge welding.<br />

Page 7

GALLERY HIGHLIGHTS FROM THE ABAVic 20th CELEBRATIONS<br />

Decorative Bowl by Mary Hackett<br />

Bookends by Malcolm Paine<br />

One branch of many of the 'Tree of Life'<br />

by <strong>Blacksmiths</strong> worldwide<br />

20th Anniversary Screen by A.B.A.Vic members Music Stand by Paul Mills<br />

Photography by Rob and Jen Kenning<br />

Page 8

Written by Stan Briggs.<br />

M E M B E R S S T O R Y<br />

Stan Briggs...life of a blacksmith<br />

At school my best subjects were woodworking and<br />

metal work. I �nished school at the age of 14 to 15<br />

years. My father, who was employed by the<br />

<strong>South</strong>ern Railways in England, got me a job in the<br />

railway work-shops where they needed a young lad.<br />

And so my career started.<br />

The workshops were situated in New Cross, a suburb<br />

of London. They were divided into two workshops.<br />

Workshop One had 3 <strong>Blacksmiths</strong> working on<br />

repairing Carriages and Steam Locomotives.<br />

Workshop Two built and repaired the timber framed<br />

coal wagons. This was where I worked.<br />

We worked a 48 hour week over 6 days, with an<br />

hour for lunch. Everyone worked on<br />

Piece work. You were paid a basic wage and then<br />

the bonus on production. The Railway had a strange<br />

way to pay wages, the Blacksmith was paid, and he<br />

in turn, paid the hammer-man, so they both got a<br />

share of the bonus money. I was paid just the basic<br />

pay.<br />

The Blacksmith I worked with was in his mid<br />

seventies and came from the West country of<br />

England, where his father had his own smithy<br />

shop. He was farrier and wheelwright and repaired<br />

agriculture machinery for many years.<br />

The best way to learn Blacksmithing was as he did,<br />

by watching and asking questions. The forge only<br />

burnt the best coke that came from steam coal. It<br />

was a soft coke but large, about the size of a football,<br />

and was kept outside the work-shop.<br />

A part of my job was to take a wheel barrow and a<br />

large wood mallet and break up the coke into small<br />

pieces, then sieve it to remove the dust, and wheel it<br />

to the forge. A barrow load would last a days work.<br />

The Blacksmith said he would teach me the art of �re<br />

welding. For <strong>this</strong> I needed a very clean �re, and he<br />

used wet coal dust around the �re and over the hot<br />

coke to make a small oven. I was shown how to<br />

bump up the metal to be welded, as you lose metal<br />

in welding and scurf.<br />

I was told to stand next to him and I was shown how<br />

to bring the metal to a welding heat using silver sand<br />

as a �ux. This also stopped the ends from burning.<br />

The power hammer was electric compressed air<br />

driven, and could used by foot control or hand lever.<br />

I was shown how to use the hand lever when the<br />

Blacksmith was forging.<br />

By the time I was 20 the Hammer-man decided to<br />

retire and I took over his job. Also a 2nd Blacksmith<br />

started. His name was George and he was Welsh, but<br />

only stayed about 6-7 months, as he took another<br />

position on the underground railway. About <strong>this</strong><br />

time the old Blacksmith said he was retiring. “About<br />

time” everyone said. He must be at least 81 years<br />

old!!, and so, I took over as the Blacksmith.<br />

Around <strong>this</strong> time the Labour Government<br />

nationalised the railways and huge cost savings were<br />

put in place. The railway wagon stock was getting<br />

too expensive to repair and they started buying all<br />

steel wagons. Also, steam was on the way out, and<br />

diesel electric locomotives replaced them.<br />

After three years as Blacksmith, I was made<br />

redundant, so I found job with SW Farmer & Sons<br />

Engineering Company. They produced construable<br />

work and balustrade. The government, at <strong>this</strong> time,<br />

was building multi storey �ats, so balustrade was<br />

needed for the stairways.<br />

Page 9

As you can imagine, there was plenty of work<br />

around.But in time, completion made it to<br />

expensive to keep on with <strong>this</strong> type of work, and it<br />

was closed down. I was o�ered work in the forging<br />

section, but as I didn't want to do <strong>this</strong> style of work, I<br />

left. I found work in a small company doing<br />

ballasting work, but within nine months I was<br />

o�ered a Blacksmith position with British Portland<br />

Cement Co. doing forging and repair work, but no<br />

�re welding.<br />

The workshop had an engineering section<br />

Blacksmith shop with 2 <strong>Blacksmiths</strong> and a boiler<br />

making section.<br />

We had an agreement that the <strong>Blacksmiths</strong> worked<br />

the bar and round metal work and the Boilermakers<br />

did plate work and Arc Welding. Sometimes, <strong>this</strong><br />

was a joint e�ort, with <strong>Blacksmiths</strong> and<br />

boilermakers working together.<br />

The company gave the employees a number of nonsaleable<br />

shares for each year of service and each<br />

year you received a bonus on each share you held<br />

on the pro�t the company made, <strong>this</strong> was paid in<br />

cash.<br />

They used to send a van to the bank with six of the<br />

biggest employee's armed with pickax handles to<br />

collect the bonus money. The money as never lost.<br />

The Cement Co. was situated in the Medway town<br />

of North�eet, so we sold our house and moved that<br />

way. I worked there for 5 years, but again the<br />

company said that production was coming to an<br />

end in a year of two, as they were running short of<br />

materials and new ways of producing cement were<br />

being found.<br />

<strong>Australia</strong>, in 1960's, was looking for skilled<br />

workers so I applied to come to <strong>Australia</strong>.<br />

As we were government assisted, they advised us to<br />

go to Melbourne. They arranged a place at the<br />

Brooklyn Hostel in Footscray.<br />

Not far from the hostel, a company called K.M<br />

Steels produced metal bar and rounds etc for the<br />

local industries, as there was a shortage of <strong>this</strong>.<br />

B.H.P only supplied <strong>this</strong> material when they were<br />

producing that run.<br />

I was able to get a job with them making entry and<br />

exit boxes for the rolling mill, and also cutting tools<br />

for the machine shop that made the rollers. For<br />

reasons I would prefer not to write, <strong>this</strong> was coming<br />

to an end.<br />

We decided we did not want to live in Melbourne<br />

after that, and we were told Adelaide might be a<br />

better place for us. I told the Hostel Authorities that<br />

I wanted a transfer to a hostel in Adelaide but was<br />

told I couldn't do <strong>this</strong>. When I asked reasons why,<br />

we were told we were migrants to Victoria not<br />

<strong>South</strong> <strong>Australia</strong>. Meanwhile, I was o�ered a job in<br />

Adelaide, and I ended up going by myself.<br />

The Hostel Authority would have to look after my<br />

family while I was gone. I was told not to do <strong>this</strong>,<br />

they would see what they could do.<br />

<strong>In</strong> a short time, we were given a transfer to a small<br />

hostel in Glenelg near the airport.<br />

I bought a 2nd hand Holden and drove to Adelaide<br />

and to the hostel. I worked for Horwood Bagshaws<br />

for a short time, then found a job as a Jibing<br />

Blacksmith with the Adelaide Steamship Co.<br />

They had a workshop at Lipson street, Port<br />

Adelaide, where I worked for 2 1/2 years.<br />

Eventually, they made <strong>this</strong> job redundant, and I<br />

transferred to the Adelaide Ship Construction at<br />

Birkenhead for another 2 1/2 years. When they<br />

closed the ship yard, myself and three others went<br />

to Freighters at Seaton, welding Sea Container's for<br />

a short time.<br />

While I was at Freighters, I saw an advert for a<br />

Blacksmith with the Adelaide Gas Co.<br />

Their workshop was located in Gilbert Street,<br />

Adelaide. The street gangs were also there. I later<br />

moved to the Brompton works, where I retired<br />

after 24 years of service.<br />

Page 10

Stan Briggs...Gallery<br />

Candle Holder<br />

Garden Gate<br />

Stan Briggs at work at S.A.G.A.S.C.O.<br />

Now that Stan has retired, he has a small forge set<br />

up at home and creates pieces of work for friends<br />

and family.<br />

Page 11

How To............. TWISTING<br />

Twisting square stock, is one of the easiest feats to accomplish for beginners. It immediately creates a<br />

pleasant shape with an otherwise boring square pro�le stock.<br />

First thing to decide is how far along the bar do you wish to twist and how many turns to give the bar to<br />

achieve the e�ect you want.<br />

With the simplest of tools, you will need a sturdy vice or post vice to hold the bar, and some form of a<br />

turning device. This can be an adjustable spanner or a custom made twisting bar.<br />

It is easy to make a twisting bar from a piece of similar stock, then weld it together.<br />

Between using a spanner and twisting bar, you will �nd it easier to maintain a straight twist with a two<br />

handed bar than a spanner, as the twisting force can be applied evenly. If you intend to do a lot of twisting<br />

work, it may pay dividends to build a jig frame with adjustable points of clamping. A jig frame allows<br />

repetitive, uniform and straight twists to be created.<br />

Which ever way you decide, another important point is even heating of the bar. An even heat gives you an<br />

even twist. If the bar is red heat one end and orange at the other, you will get a twist that goes from tight to<br />

loose.<br />

by Rob Kenning<br />

As an example, we will do a 10cm twist on some 12mm square stock.<br />

Mark with a scriber or marble chalk, where the twist is going and place that section in the �re to a depth of<br />

one third down from the top of the �re and give the section a good soaking heat. Meantime, set up your<br />

tools ready to move quickly.<br />

When the section is evenly coloured light orange, remove the bar from the �re and clamp the piece on the<br />

outside of one of your marked points. Then �t the tool and evenly turn the tool one or two full turns,<br />

depending on how tight you want the twist.<br />

If you �nd that the twist is distorted, don't use a steel hammer to straighten it out or you will damage the<br />

pro�le. <strong>In</strong>stead, use a wooden stump and a block of wood or wooden mallet to bring it straight.<br />

Good luck and good forging.<br />

Degrees of twist<br />

Page 12

<strong>Blacksmiths</strong> <strong>Association</strong>s<br />

<strong>Blacksmiths</strong> <strong>Association</strong> Western <strong>Australia</strong><br />

http://bawa.webkroll.com/<br />

<strong>Australia</strong>n <strong>Blacksmiths</strong> <strong>Association</strong> Victoria<br />

http://www.abavic.org.au/<br />

British <strong>Artist</strong> <strong>Blacksmiths</strong> <strong>Association</strong><br />

http://www.baba.org.uk/<br />

<strong>Artist</strong> <strong>Blacksmiths</strong> <strong>Association</strong> of America <strong>In</strong>c<br />

http://www.abana.org/<br />

<strong>Blacksmiths</strong> <strong>In</strong>formation and Forums<br />

All styles of metalcraft information<br />

http://www.metalartistforum.com/<br />

All styles of Blacksmith information<br />

http://www.iforgeiron.com/forum/<br />

Social networking for the metal arts<br />

http://www.artmetal.com/index.php<br />

David Robertson (Ontario <strong>Artist</strong> Blacksmith)<br />

http://www.artistblacksmith.com/<br />

Useful Sites and Suppliers<br />

<strong>Blacksmiths</strong> Supplies<br />

Stirling Fuel Supplies<br />

Mount Barker Rd Cnr Gould Rd, STIRLING, SA 5152<br />

Phone: (08) 83392021<br />

Metalcorp Steel<br />

285 Grand Junction Road OTTOWAY SA 5013<br />

Phone: (08) 8301 3777<br />

Email: Bronwyn.Garrick@bluescopesteel.com<br />

<strong>South</strong>ern Steel Supplies<br />

69- 71 O'Sullivan Beach Rd LONSDALE SA 5160<br />

Phone: 1300 302 993<br />

Horse Shoes 'R' Us<br />

9 Alabar Crs GLOBE DERBY PARK SA 5110<br />

Phone: (08) 8281 0689<br />

Fantech Pty Ltd<br />

17A Seaforth Avenue SOMERTON PARK SA 5044<br />

Phone:(08) 83770502<br />

EBM Blowers<br />

17/ 2 Portrush Rd PAYNEHAM SA 5070<br />

Phone: (08) 88363544<br />

If you have any contacts and web sites you<br />

would like to have included, contact the<br />

Secretary.<br />

Page 13