ETA blown film dies and internal bubble cooling systems - an ideal ...

ETA blown film dies and internal bubble cooling systems - an ideal ... ETA blown film dies and internal bubble cooling systems - an ideal ...

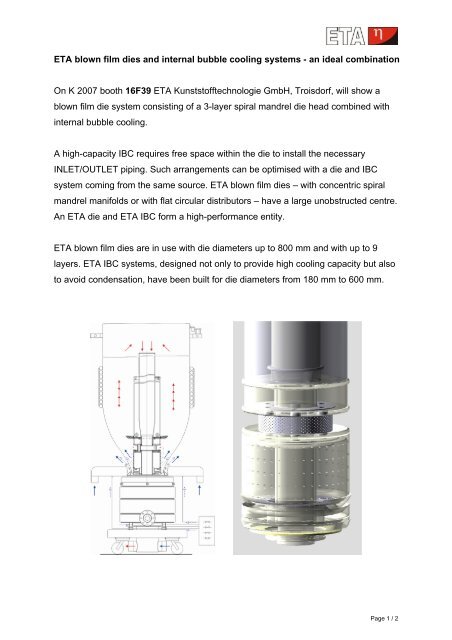

ETA blown film dies and internal bubble cooling systems - an ideal combination On K 2007 booth 16F39 ETA Kunststofftechnologie GmbH, Troisdorf, will show a blown film die system consisting of a 3-layer spiral mandrel die head combined with internal bubble cooling. A high-capacity IBC requires free space within the die to install the necessary INLET/OUTLET piping. Such arrangements can be optimised with a die and IBC system coming from the same source. ETA blown film dies – with concentric spiral mandrel manifolds or with flat circular distributors – have a large unobstructed centre. An ETA die and ETA IBC form a high-performance entity. ETA blown film dies are in use with die diameters up to 800 mm and with up to 9 layers. ETA IBC systems, designed not only to provide high cooling capacity but also to avoid condensation, have been built for die diameters from 180 mm to 600 mm. Page 1 / 2

<strong>ETA</strong> <strong>blown</strong> <strong>film</strong> <strong>dies</strong> <strong><strong>an</strong>d</strong> <strong>internal</strong> <strong>bubble</strong> <strong>cooling</strong> <strong>systems</strong> - <strong>an</strong> <strong>ideal</strong> combination<br />

On K 2007 booth 16F39 <strong>ETA</strong> Kunststofftechnologie GmbH, Troisdorf, will show a<br />

<strong>blown</strong> <strong>film</strong> die system consisting of a 3-layer spiral m<strong><strong>an</strong>d</strong>rel die head combined with<br />

<strong>internal</strong> <strong>bubble</strong> <strong>cooling</strong>.<br />

A high-capacity IBC requires free space within the die to install the necessary<br />

INLET/OUTLET piping. Such arr<strong>an</strong>gements c<strong>an</strong> be optimised with a die <strong><strong>an</strong>d</strong> IBC<br />

system coming from the same source. <strong>ETA</strong> <strong>blown</strong> <strong>film</strong> <strong>dies</strong> – with concentric spiral<br />

m<strong><strong>an</strong>d</strong>rel m<strong>an</strong>ifolds or with flat circular distributors – have a large unobstructed centre.<br />

An <strong>ETA</strong> die <strong><strong>an</strong>d</strong> <strong>ETA</strong> IBC form a high-perform<strong>an</strong>ce entity.<br />

<strong>ETA</strong> <strong>blown</strong> <strong>film</strong> <strong>dies</strong> are in use with die diameters up to 800 mm <strong><strong>an</strong>d</strong> with up to 9<br />

layers. <strong>ETA</strong> IBC <strong>systems</strong>, designed not only to provide high <strong>cooling</strong> capacity but also<br />

to avoid condensation, have been built for die diameters from 180 mm to 600 mm.<br />

Page 1 / 2

17 August 2007<br />

Contact: Robert Michels<br />

<strong>ETA</strong> Kunststofftechnologie GmbH<br />

Biberweg 4<br />

53842 Troisdorf / Germ<strong>an</strong>y<br />

Fon: +49 / 2241 / 949707<br />

Fax: +49 / 2241 / 949709<br />

mail@eta-gmbh.de<br />

www.eta-gmbh.de<br />

Page 2 / 2