eerless P - Lane Punch Corporation

eerless P - Lane Punch Corporation

eerless P - Lane Punch Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

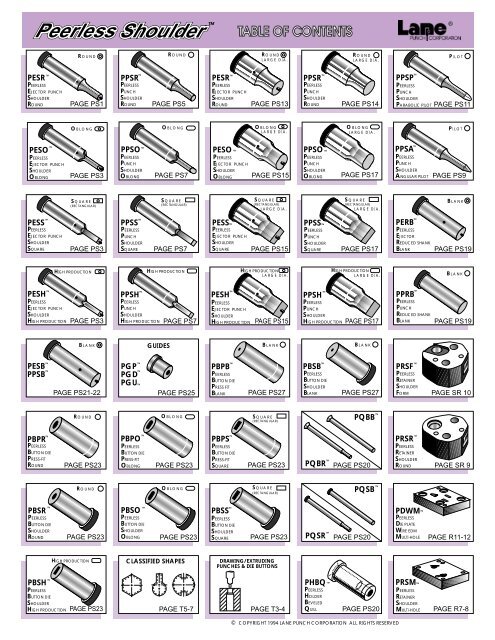

P<strong>eerless</strong> Shoulder<br />

PESR<br />

PEERLESS<br />

<br />

EJECTOR PUNCH<br />

SHOULDER<br />

ROUND<br />

PESO<br />

PEERLESS<br />

<br />

EJECTOR PUNCH<br />

SHOULDER<br />

OBLONG<br />

PESS<br />

PEERLESS<br />

<br />

EJECTOR PUNCH<br />

R OUND<br />

PAGE PS1<br />

O BLONG<br />

PAGE PS3<br />

S QUARE<br />

(RECTANGULAR)<br />

SHOULDER<br />

SQUARE PAGE PS3<br />

PESH<br />

PEERLESS<br />

<br />

EJECTOR PUNCH<br />

SHOULDER<br />

HIGH PRODUCTION<br />

PESB<br />

PPSB<br />

<br />

<br />

PBPR<br />

PEERLESS<br />

<br />

BUTTON DIE<br />

HIGH PRODUCTION<br />

PAGE PS3<br />

B LANK<br />

PAGE PS21-22<br />

PRESS-FIT<br />

ROUND PAGE PS23<br />

PBSR<br />

PEERLESS<br />

<br />

BUTTON DIE<br />

R OUND<br />

SHOULDER<br />

ROUND PAGE PS23<br />

PBSH<br />

PEERLESS<br />

BUTTON DIE<br />

<br />

R OUND<br />

HIGH PRODUCTION<br />

SHOULDER<br />

HIGH PRODUCTION PAGE PS23<br />

PPSR<br />

PEERLESS<br />

<br />

PUNCH<br />

SHOULDER<br />

ROUND<br />

PPSO<br />

PEERLESS<br />

<br />

PUNCH<br />

SHOULDER<br />

OBLONG<br />

PPSS<br />

PEERLESS<br />

PUNCH<br />

SHOULDER<br />

SQUARE<br />

<br />

PPSH<br />

PEERLESS<br />

<br />

PUNCH<br />

SHOULDER<br />

HIGH PRODUCTION<br />

PGP<br />

PGD<br />

PGU<br />

<br />

<br />

<br />

PBPO<br />

PEERLESS<br />

<br />

BUTTON DIE<br />

R OUND<br />

PAGE PS5<br />

O BLONG<br />

PAGE PS7<br />

HIGH PRODUCTION<br />

GUIDES<br />

PAGE PS7<br />

PAGE PS25<br />

PRESS-FIT<br />

OBLONG PAGE PS23<br />

PBSO<br />

PEERLESS<br />

<br />

BUTTON DIE<br />

S QUARE<br />

(RECTANGULAR)<br />

PAGE PS7<br />

O BLONG<br />

O BLONG<br />

SHOULDER<br />

OBLONG PAGE PS23<br />

CLASSIFIED SHAPES<br />

PAGE T5-7<br />

<br />

PESR<br />

PEERLESS<br />

EJECTOR PUNCH<br />

SHOULDER<br />

ROUND<br />

<br />

PESO <br />

PEERLESS<br />

EJECTOR PUNCH<br />

SHOULDER<br />

OBLONG<br />

PESS<br />

PEERLESS<br />

EJECTOR PUNCH<br />

S QUARE<br />

(RECTANGULAR)<br />

LARGE DIA.<br />

SHOULDER<br />

SQUARE PAGE PS15<br />

PESH <br />

PEERLESS<br />

EJECTOR PUNCH<br />

HIGH PRODUCTION<br />

LARGE DIA.<br />

SHOULDER<br />

HIGH PRODUCTION PAGE PS15<br />

PBPB<br />

PEERLESS<br />

<br />

BUTTON DIE<br />

PRESS FIT<br />

BLANK<br />

PBPS<br />

PEERLESS<br />

BUTTON DIE<br />

PRESS-FIT<br />

SQUARE<br />

<br />

PBSS <br />

PEERLESS<br />

BUTTON DIE<br />

TABLE OF CONTENTS<br />

ROUND<br />

LARGE DIA.<br />

PAGE PS13<br />

O BLONG<br />

LARGE DIA.<br />

PAGE PS15<br />

B LANK<br />

PAGE PS27<br />

S QUARE<br />

(RECTANGULAR)<br />

PAGE PS23<br />

S QUARE<br />

(RECTANGULAR)<br />

SHOULDER<br />

SQUARE PAGE PS23<br />

DRAWING/EXTRUDING<br />

PUNCHES & DIE BUTTONS<br />

PAGE T3-4<br />

PPSR<br />

PEERLESS<br />

<br />

PUNCH<br />

SHOULDER<br />

ROUND<br />

PPSO <br />

PEERLESS<br />

PUNCH<br />

SHOULDER<br />

OBLONG<br />

PPSS<br />

PEERLESS<br />

PUNCH<br />

SHOULDER<br />

SQUARE<br />

PPSH<br />

PEERLESS<br />

<br />

PUNCH<br />

SHOULDER<br />

HIGH PRODUCTION<br />

PBSB<br />

PEERLESS<br />

<br />

BUTTON DIE<br />

SHOULDER<br />

BLANK<br />

PQBR <br />

PQSR <br />

PHBQ <br />

PEERLESS<br />

HOLDER<br />

BEVELED<br />

QUILL<br />

ROUND<br />

LARGE DIA.<br />

PAGE PS14<br />

O BLONG<br />

LARGE DIA.<br />

PAGE PS17<br />

S QUARE<br />

(RECTANGULAR)<br />

LARGE DIA.<br />

PAGE PS17<br />

HIGH PRODUCTION<br />

LARGE DIA.<br />

PAGE PS17<br />

B LANK<br />

© COPYRIGHT 1994 LANE PUNCH CORPORATION ALL RIGHTS RESERVED<br />

PPSP <br />

PEERLESS<br />

PUNCH<br />

SHOULDER<br />

PARABOLIC PILOT<br />

PPSA <br />

PEERLESS<br />

PUNCH<br />

P ILOT<br />

PAGE PS11<br />

P ILOT<br />

SHOULDER<br />

ANGULAR PILOT PAGE PS9<br />

PERB<br />

PEERLESS<br />

<br />

EJECTOR<br />

REDUCED SHANK<br />

BLANK<br />

PPRB<br />

PEERLESS<br />

<br />

PUNCH<br />

B LANK<br />

PAGE PS19<br />

B LANK<br />

REDUCED SHANK<br />

BLANK PAGE PS19<br />

PRSF<br />

PEERLESS<br />

<br />

RETAINER<br />

SHOULDER<br />

PAGE PS27 FORM PAGE SR 10<br />

PQBB <br />

PAGE PS20<br />

PQSB <br />

PAGE PS20<br />

PAGE PS20<br />

PRSR<br />

PEERLESS<br />

<br />

RETAINER<br />

SHOULDER<br />

ROUND PAGE SR 9<br />

PDWM<br />

PEERLESS<br />

DIE PLATE<br />

WIRE EDM<br />

MULTI-HOLE<br />

PRSM<br />

PEERLESS<br />

RETAINER<br />

SHOULDER<br />

MULTI-HOLE<br />

®<br />

PAGE R11-12<br />

PAGE R7-8

P<strong>eerless</strong> Ejector Shoulder<br />

+.010<br />

+.005<br />

.188*<br />

L +.020<br />

+.010<br />

Fillet<br />

.01<br />

.02<br />

D<br />

B +.06<br />

-.0<br />

D + .125<br />

* .125 WHEN D = .1875<br />

POINT LENGTH<br />

PS1<br />

.50<br />

.75<br />

1.00<br />

1.25<br />

1.50<br />

®<br />

+.0<br />

-.010<br />

+.0004<br />

+.0002<br />

D - .001<br />

Lead-In<br />

.5R Blend<br />

Radius<br />

B<br />

.50<br />

A<br />

.75<br />

B<br />

1.00<br />

C<br />

1.25<br />

D<br />

1.50<br />

E<br />

P Ejector S houlder R ound<br />

PEERLESS<br />

EJECTOR<br />

SHOULDER<br />

ROUND<br />

CATALOG<br />

NUMBER<br />

PESR 187*<br />

PESR 250<br />

PESR 312<br />

PESR 375<br />

PESR 187*<br />

PESR 250<br />

PESR 312<br />

PESR 375<br />

PESR 437<br />

PESR 500<br />

PESR 625<br />

PESR 750<br />

PESR 1000<br />

PESR 187*<br />

PESR 250<br />

PESR 312<br />

PESR 375<br />

PESR 437<br />

PESR 500<br />

PESR 625<br />

PESR 750<br />

PESR 1000<br />

PESR 250<br />

PESR 312<br />

PESR 375<br />

PESR 437<br />

PESR 500<br />

PESR 625<br />

PESR 750<br />

PESR 1000<br />

PESR 312<br />

PESR 375<br />

PESR 437<br />

PESR 500<br />

PESR 625<br />

PESR 750<br />

PESR 1000<br />

<strong>eerless</strong><br />

+ .0002<br />

P Tolerance - .0<br />

P TO D .0003<br />

P<br />

PESR <br />

MIN.<br />

P<br />

.050<br />

A2,<br />

M2,<br />

PS,<br />

R/c 59-61 double tempered<br />

R/c 61-63 triple tempered<br />

R/c 62-64 triple tempered<br />

Heads are drawn to 40-55 Rc.<br />

The principles of <strong>Lane</strong> in-house heat<br />

treatment is to provide quality products<br />

to users with the best combination of<br />

toughness and wear resistance.<br />

Wear-resistant coatings are available<br />

on M2 & PS. See Technical Section.<br />

To provide perpendicularity to retainer at<br />

time of insertion, shank lead-in diameter<br />

is reduced by .001 for length of .250 inch.<br />

Ordering Example:<br />

(12) PESR 1000-D325 M2 P.870<br />

SHANK<br />

DIA. D<br />

.1875<br />

OVERALL LENGTH (L)<br />

1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00<br />

A125<br />

A150<br />

A175<br />

A200<br />

A225<br />

A250<br />

.080 .2500 A125 A150 A175 A200 A225 A250<br />

.115 .3125 A125 A150 A175 A200 A225 A250<br />

.158 .3750 A125 A150 A175 A200 A225 A250<br />

.050 .1875<br />

B150 B175 B200 B225 B250<br />

.080 .2500<br />

B150 B175 B200 B225 B250<br />

.115 .3125<br />

B150 B175 B200 B225 B250<br />

.158 .3750<br />

B150 B175 B200 B225 B250<br />

.158 .4375<br />

B150 B175 B200 B225 B250<br />

.158 .5000<br />

B150 B175 B200 B225 B250<br />

.235 .6250<br />

B150 B175 B200 B225 B250<br />

.300 .7500<br />

B150 B175 B200 B225 B250<br />

.400 1.0000<br />

B150 B175 B200 B225 B250<br />

.058 .1875<br />

C175 C200 C225 C250<br />

.080 .2500<br />

C175 C200 C225 C250<br />

.115 .3125<br />

C175 C200 C225 C250<br />

.158 .3750<br />

C175 C200 C225 C250<br />

.158 .4375<br />

C175 C200 C225 C250<br />

.158 .5000<br />

C175 C200 C225 C250<br />

.235 .6250<br />

C175 C200 C225 C250<br />

.300 .7500<br />

C175 C200 C225 C250<br />

.400 1.0000<br />

C175 C200 C225 C250<br />

.080 .2500<br />

D200 D225 D250<br />

.115 .3125<br />

D200 D225 D250<br />

.158 .3750<br />

D200 D225 D250<br />

.158 .4375<br />

D200 D225 D250<br />

.158 .5000<br />

D200 D225 D250<br />

.235 .6250<br />

D200 D225 D250<br />

.300 .7500<br />

D200 D225 D250<br />

.400 1.0000<br />

D200 D225 D250<br />

.115 .3125<br />

E225 E250<br />

.158 .3750<br />

E225 E250<br />

.158 .4375<br />

E225 E250<br />

.158 .5000<br />

E225 E250<br />

.235 .6250<br />

E225 E250<br />

.300 .7500<br />

E225 E250<br />

.400 1.0000<br />

E225 E250<br />

** Replacement Ejector Components are defined in Technical Section.<br />

A275<br />

A275<br />

A275<br />

A275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

<br />

Classified shapes are fully<br />

defined in Technical Section.<br />

A300<br />

A300<br />

A300<br />

A300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300

P Ejector S houlder R ound<br />

CATALOG<br />

NUMBER<br />

PESR 187*<br />

PESR 250<br />

PESR 312<br />

PESR 375<br />

PESR 187*<br />

PESR 250<br />

PESR 312<br />

PESR 375<br />

PESR 437<br />

PESR 500<br />

PESR 625<br />

PESR 750<br />

PESR 1000<br />

PESR 187*<br />

PESR 250<br />

PESR 312<br />

PESR 375<br />

PESR 437<br />

PESR 500<br />

PESR 625<br />

PESR 750<br />

PESR 1000<br />

PESR 250<br />

PESR 312<br />

PESR 375<br />

PESR 437<br />

PESR 500<br />

PESR 625<br />

PESR 750<br />

PESR 1000<br />

PESR 312<br />

PESR 375<br />

PESR 437<br />

PESR 500<br />

PESR 625<br />

PESR 750<br />

PESR 1000<br />

<strong>eerless</strong><br />

P<strong>eerless</strong> Shoulder punches are the ultimate of precision tolerancing;<br />

OVERALL LENGTH (L)<br />

3.25 3.50 3.75 4.00<br />

A325<br />

A325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

A350<br />

A350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

P & W Tolerance<br />

A375<br />

B375<br />

B375<br />

B375<br />

B375<br />

B375<br />

B375<br />

B375<br />

C375<br />

C375<br />

C375<br />

C375<br />

C375<br />

C375<br />

C375<br />

D375<br />

D375<br />

D375<br />

D375<br />

D375<br />

D375<br />

D375<br />

E375<br />

E375<br />

E375<br />

E375<br />

E375<br />

E375<br />

E375<br />

B400<br />

B400<br />

B400<br />

B400<br />

B400<br />

B400<br />

C400<br />

C400<br />

C400<br />

C400<br />

C400<br />

C400<br />

C400<br />

D400<br />

D400<br />

D400<br />

D400<br />

D400<br />

D400<br />

D400<br />

E400<br />

E400<br />

E400<br />

E400<br />

E400<br />

E400<br />

E400<br />

+ .0002<br />

- .0 P & W to D .0003<br />

• Rap-i-Die introduces a NEW way to make rapid Engineering changes.<br />

• Send us a drawing of your present retainer and we will replace it incorporating your change.<br />

• During your next maintenance interval, mount the new retainer on your existing dowel<br />

locations and you’re ready to go back in the press.<br />

• SUMMARY: Rap-i-Die helps you get a head-start while your die is still running in the press.<br />

EJECT.<br />

SIZE**<br />

E2A<br />

E3<br />

E4<br />

E6<br />

E2A<br />

E3<br />

E4<br />

E6<br />

E6<br />

E6<br />

E9<br />

E9<br />

E9<br />

E2A<br />

E3<br />

E4<br />

E6<br />

E6<br />

E6<br />

E9<br />

E9<br />

E9<br />

E3<br />

E4<br />

E6<br />

E6<br />

E6<br />

E9<br />

E9<br />

E9<br />

E4<br />

E6<br />

E6<br />

E6<br />

E9<br />

E9<br />

E9<br />

<br />

STRAIGHT BEFORE RADIUS<br />

D-P<br />

2<br />

Shank Dia.<br />

.500<br />

.468<br />

.437<br />

.406<br />

.375<br />

.343<br />

.312<br />

.281<br />

.250<br />

.218<br />

.187<br />

.156<br />

.125<br />

.093<br />

.062<br />

Calculating usable Straight Before Radius (SBR)<br />

1. Subtract smaller of point size "P" if round or "W"<br />

if shaped from Shank Diameter "D" and divide by 2.<br />

D-P (or "W")<br />

2<br />

2. Locate the D-P total on the horizontal axis<br />

2 at top right of graph.<br />

3. The intersection point of this line at radius establishes<br />

the length of radius, "read on the vertical axis at left.<br />

Your answer is length of Radius (LR).<br />

4. Subtract LR from your desired Point Length "B" to<br />

determine the Straight Before Radius " (SBR).<br />

0<br />

S B R = "B" - "LR"<br />

.500 RAD<br />

PRSM 400-600 Det. 6-114 6/93<br />

PSWM 400-600 Det. 6-114 6/93<br />

PDWM 400-600 Det. 6-114 6/93<br />

0 .100 .200<br />

D-P<br />

2<br />

.300 .400<br />

SMALLEST<br />

of "P" or "W"<br />

SBR<br />

Example: D = .750 P = .330 B = .75<br />

D-P<br />

1. 2 = (.750 -.330) ÷ 2 = .210<br />

2. The .210 line intersects the radius at .406<br />

3. B - LR = SBR .75 - .406 = .344 (SBR)<br />

B<br />

®<br />

PS2

PS3<br />

P<strong>eerless</strong> Ejector Shoulder<br />

+.010<br />

+.005<br />

.188*<br />

L +.020<br />

+.010<br />

POINT LENGTH<br />

.50<br />

Fillet<br />

.01<br />

.02<br />

D<br />

B +.06<br />

-.0<br />

.75<br />

1.00<br />

1.25<br />

1.50<br />

®<br />

D + .125<br />

* .125 WHEN D = .1875<br />

+.0<br />

-.010<br />

+.0004<br />

+.0002<br />

D - .001<br />

Lead-In<br />

.5R Blend<br />

Radius<br />

B<br />

CATALOG<br />

NUMBER<br />

PESO 187<br />

.50<br />

PESO 250<br />

A<br />

.75<br />

B<br />

1.00<br />

C<br />

1.25<br />

D<br />

1.50<br />

E<br />

P<br />

PEERLESS<br />

EJECTOR<br />

SHOULDER<br />

OBLONG<br />

P<br />

<strong>eerless</strong><br />

+ .0002<br />

P & W Tolerance - .0<br />

P & W TO D .0003<br />

W<br />

PESO 312<br />

PESO 375<br />

PESO 187<br />

PESO 250<br />

PESO 312<br />

PESO 375<br />

PESO 437<br />

PESO 500<br />

PESO 625<br />

PESO 750<br />

PESO 1000<br />

PESO 187<br />

PESO 250<br />

PESO 312<br />

PESO 375<br />

PESO 437<br />

PESO 500<br />

PESO 625<br />

PESO 750<br />

PESO 1000<br />

PESO 250<br />

PESO 312<br />

PESO 375<br />

PESO 437<br />

PESO 500<br />

PESO 625<br />

PESO 750<br />

PESO 1000<br />

PESO 312<br />

PESO 375<br />

PESO 437<br />

PESO 500<br />

PESO 625<br />

PESO 750<br />

PESO 1000<br />

PESO <br />

MIN.<br />

W<br />

.062<br />

.080<br />

.115<br />

.158<br />

.062<br />

.080<br />

.115<br />

.158<br />

.158<br />

.158<br />

.235<br />

.235<br />

.235<br />

.093<br />

.093<br />

.115<br />

.158<br />

.158<br />

.158<br />

.235<br />

.235<br />

.235<br />

.093<br />

.115<br />

.158<br />

.158<br />

.158<br />

.235<br />

.235<br />

.235<br />

.115<br />

.158<br />

.158<br />

.158<br />

.235<br />

.235<br />

.235<br />

E jector S houlder<br />

PEERLESS<br />

EJECTOR<br />

SHOULDER<br />

SQUARE/RECTANGLE<br />

+ .0002<br />

P & W Tolerance - .0<br />

P & W TO D .0003<br />

P<br />

P + W<br />

G must not exceed shank dia.<br />

2<br />

2<br />

G=<br />

CATALOG<br />

NUMBER<br />

PESS <br />

W<br />

G<br />

MIN.<br />

W<br />

PEERLESS<br />

EJECTOR<br />

SHOULDER<br />

HIGH PRODUCTION<br />

O<br />

S<br />

H<br />

CATALOG<br />

NUMBER<br />

=<br />

=<br />

=<br />

+ .0002<br />

P & W Tolerance - .0<br />

P & W TO D .0003<br />

P<br />

PESH <br />

SHANK<br />

DIA. D<br />

PESS 187 .062 PESH 187 .062 .1875<br />

PESS 250 .080 PESH 250 .080 .2500<br />

PESS 312 .115 PESH 312 .115 .3125<br />

PESS 375 .158 PESH 375 .158 .3750<br />

PESS 187 .062 PESH 187 .062 .1875<br />

PESS 250 .080 PESH 250 .080 .2500<br />

PESS 312 .115 PESH 312 .115 .3125<br />

PESS 375 .158 PESH 375 .158 .3750<br />

PESS 437 .158 PESH 437 .158 .4375<br />

PESS 500 .158 PESH 500 .158 .5000<br />

PESS 625 .235 PESH 625 .235 .6250<br />

PESS 750 .235 PESH 750 .235 .7500<br />

PESS 1000 .235 PESH 1000 .235 1.0000<br />

PESS 187 .093 PESH 187 .093 .1875<br />

PESS 250 .093 PESH 250 .093 .2500<br />

PESS 312 .115 PESH 312 .115 .3125<br />

PESS 375 .158 PESH 375 .158 .3750<br />

PESS 437 .158 PESH 437 .158 .4375<br />

PESS 500 .158 PESH 500 .158 .5000<br />

PESS 625 .235 PESH 625 .235 .6250<br />

PESS 750 .235 PESH 750 .235 .7500<br />

PESS 1000 .235 PESH 1000 .235 1.0000<br />

PESS 250 .093 PESH 250 .093 .2500<br />

PESS 312 .115 PESH 312 .115 .3125<br />

PESS 375 .158 PESH 375 .158 .3750<br />

PESS 437 .158 PESH 437 .158 .4375<br />

PESS 500 .158 PESH 500 .158 .5000<br />

PESS 625 .235 PESH 625 .235 .6250<br />

PESS 750 .235 PESH 750 .235 .7500<br />

PESS 1000 .235 PESH 1000 .235 1.0000<br />

PESS 312 .115 PESH 312 .115 .3125<br />

PESS 375 .158 PESH 375 .158 .3750<br />

PESS 437 .158 PESH 437 .158 .4375<br />

PESS 500 .158 PESH 500 .158 .5000<br />

PESS 625 .235 PESH 625 .235 .6250<br />

PESS 750 .235 PESH 750 .235 .7500<br />

PESS 1000 .235 PESH 1000 .235 1.0000<br />

** Replacement Ejector Components are defined in Technical Section.<br />

W<br />

G<br />

+.0002<br />

-.0000<br />

R.020<br />

(P-.040) 2 + (W-.040) 2 G=[ ] + .040<br />

MIN.<br />

W<br />

<br />

"SBR," Straight<br />

before Radius<br />

chart page PS2.<br />

Heads are drawn<br />

to 40-55 Rc.<br />

EJECT.<br />

SIZE**<br />

E2A<br />

E3<br />

E4<br />

E6<br />

E2A<br />

E3<br />

E4<br />

E6<br />

E6<br />

E6<br />

E9<br />

E9<br />

E9<br />

E2A<br />

E3<br />

E4<br />

E6<br />

E6<br />

E6<br />

E9<br />

E9<br />

E9<br />

E3<br />

E4<br />

E6<br />

E6<br />

E6<br />

E9<br />

E9<br />

E9<br />

E4<br />

E6<br />

E6<br />

E6<br />

E9<br />

E9<br />

E9

SHANK<br />

DIA. D<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

P<br />

<strong>eerless</strong><br />

Suggestions on selecting the High<br />

Production "H" style punch point.<br />

1. Standard rectangular or<br />

square die buttons have a<br />

.007" radius in the corners.<br />

This is consistent with all<br />

manufacturers.<br />

2. This die button corner<br />

radius frequently interferes<br />

with the sharp corners of a<br />

standard rectangular punch,<br />

causing premature failure of<br />

the punch. It causes drag<br />

type burrs at each corner of<br />

the punched hole.<br />

CATALOG<br />

NUMBER<br />

PES_ O/S/H 187<br />

PES_ O/S/H 250<br />

PES_ O/S/H 312<br />

PES_ O/S/H 375<br />

PES_ O/S/H 187<br />

PES_ O/S/H 250<br />

PES_ O/S/H 312<br />

PES_ O/S/H 375<br />

PES_ O/S/H 437<br />

PES_ O/S/H 500<br />

PES_ O/S/H 625<br />

PES_ O/S/H 750<br />

PES_ O/S/H 1000<br />

PES_ O/S/H 187<br />

PES_ O/S/H 250<br />

PES_ O/S/H 312<br />

PES_ O/S/H 375<br />

PES_ O/S/H 437<br />

PES_ O/S/H 500<br />

PES_ O/S/H 625<br />

PES_ O/S/H 750<br />

PES_ O/S/H 1000<br />

PES_ O/S/H 250<br />

PES_ O/S/H 312<br />

PES_ O/S/H 375<br />

PES_ O/S/H 437<br />

PES_ O/S/H 500<br />

PES_ O/S/H 625<br />

PES_ O/S/H 750<br />

PES_ O/S/H 1000<br />

PES_ O/S/H 312<br />

PES_ O/S/H 375<br />

PES_ O/S/H 437<br />

PES_ O/S/H 500<br />

PES_ O/S/H 625<br />

PES_ O/S/H 750<br />

PES_ O/S/H 1000<br />

Ejector S houlder<br />

3. The "H" style punch will<br />

eliminate this interference<br />

and greatly increase your<br />

stamping production from<br />

rectangular and square<br />

punches.<br />

4. Your punch life will<br />

increase, down-time<br />

will be reduced, your<br />

average manufacturing<br />

cost-per-stamping will<br />

be lowered.<br />

OVERALL LENGTH (L)<br />

1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00<br />

A125<br />

A125<br />

A125<br />

A125<br />

A150<br />

A150<br />

A150<br />

A150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

A175<br />

A175<br />

A175<br />

A175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

A200<br />

A200<br />

A200<br />

A200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

A225<br />

A225<br />

A225<br />

A225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

A250<br />

A250<br />

A250<br />

A250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

O<br />

S<br />

H<br />

A2,<br />

M2,<br />

PS,<br />

Classified shapes are fully<br />

defined on Pg.T 5-7 in<br />

Technical Section.<br />

A275<br />

A275<br />

A275<br />

A275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

R/c 59-61 double tempered<br />

R/c 61-63 triple tempered<br />

R/c 62-64 triple tempered<br />

The principles of <strong>Lane</strong> in-house heat treatment is to provide<br />

quality products to users with the best combination of<br />

toughness and wear resistance.<br />

Ordering Example:<br />

(12) PESO 1000-D325 M2 P.870 W.371 K2*<br />

180˚<br />

=<br />

=<br />

=<br />

90˚<br />

270˚<br />

K2<br />

0˚<br />

* Radial locking devices for shapes are detailed Pg. T9-10 in Technical Section.<br />

180˚<br />

<br />

A300<br />

A300<br />

A300<br />

A300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300<br />

90˚<br />

270˚<br />

K3<br />

0˚<br />

A325<br />

A325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

180˚<br />

90˚<br />

270˚<br />

K4<br />

A350<br />

A350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

0˚<br />

A375<br />

B375<br />

B375<br />

B375<br />

B375<br />

B375<br />

B375<br />

B375<br />

C375<br />

C375<br />

C375<br />

C375<br />

C375<br />

C375<br />

C375<br />

D375<br />

D375<br />

D375<br />

D375<br />

D375<br />

D375<br />

D375<br />

E375<br />

E375<br />

E375<br />

E375<br />

E375<br />

E375<br />

E375<br />

®<br />

B400<br />

B400<br />

B400<br />

B400<br />

B400<br />

B400<br />

C400<br />

C400<br />

C400<br />

C400<br />

C400<br />

C400<br />

C400<br />

D400<br />

D400<br />

D400<br />

D400<br />

D400<br />

D400<br />

D400<br />

E400<br />

E400<br />

E400<br />

E400<br />

E400<br />

E400<br />

E400<br />

PS4

PS5<br />

P<strong>eerless</strong> <strong>Punch</strong> Shoulder<br />

Round<br />

+.010<br />

+.005<br />

L +.020<br />

+.010<br />

.188*<br />

B +.06<br />

-.0<br />

* .125 WHEN D = .1875 OR .1250<br />

POINT LENGTH<br />

.50<br />

Fillet<br />

.01<br />

.02<br />

D<br />

.75<br />

1.00<br />

1.25<br />

1.50<br />

®<br />

D + .125<br />

+.0<br />

-.010<br />

+.0004<br />

+.0002<br />

D - .001<br />

Lead-In<br />

.5R Blend<br />

Radius<br />

B<br />

.50<br />

A<br />

.75<br />

B<br />

1.00<br />

C<br />

1.25<br />

D<br />

1.50<br />

E<br />

P <strong>Punch</strong> S houlder Round<br />

PEERLESS<br />

PUNCH<br />

SHOULDER<br />

ROUND<br />

P Tolerance<br />

+ .0002<br />

- .0<br />

P TO D .0003<br />

P<br />

CATALOG<br />

NUMBER MIN.<br />

P<br />

PPSR 125<br />

PPSR 187<br />

PPSR 250<br />

PPSR 312<br />

PPSR 375<br />

PPSR 125<br />

PPSR 187<br />

PPSR 250<br />

PPSR 312<br />

PPSR 375<br />

PPSR 437<br />

PPSR 500<br />

PPSR 625<br />

PPSR 750<br />

PPSR 1000<br />

PPSR 125<br />

PPSR 187<br />

PPSR 250<br />

PPSR 312<br />

PPSR 375<br />

PPSR 437<br />

PPSR 500<br />

PPSR 625<br />

PPSR 750<br />

PPSR 1000<br />

PPSR 125<br />

PPSR 187<br />

PPSR 250<br />

PPSR 312<br />

PPSR 375<br />

PPSR 437<br />

PPSR 500<br />

PPSR 625<br />

PPSR 750<br />

PPSR 1000<br />

PPSR 187<br />

PPSR 250<br />

PPSR 312<br />

PPSR 375<br />

PPSR 437<br />

PPSR 500<br />

PPSR 625<br />

PPSR 750<br />

PPSR 1000<br />

<strong>eerless</strong><br />

PPSR <br />

.031<br />

.042<br />

.062<br />

.062<br />

.062<br />

.042<br />

.042<br />

.062<br />

.062<br />

.062<br />

.093<br />

.125<br />

.235<br />

.300<br />

.400<br />

.058<br />

.058<br />

.062<br />

.062<br />

.062<br />

.093<br />

.125<br />

.235<br />

.300<br />

.400<br />

.075<br />

.075<br />

.080<br />

.093<br />

.093<br />

.093<br />

.125<br />

.235<br />

.300<br />

.400<br />

.093<br />

.093<br />

.093<br />

.125<br />

.125<br />

.125<br />

.235<br />

.300<br />

.400<br />

A2,<br />

M2,<br />

PS,<br />

Heads are drawn to 40-55 Rc.<br />

To provide perpendicularity to retainer at<br />

time of insertion, shank lead-in diameter<br />

is reduced by .001 for length of .250 inch.<br />

Wear-resistant coatings are available on<br />

M2 & PS. See Technical Section.<br />

Classified shapes are fully defined in<br />

Technical Section.<br />

MAX.<br />

P<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

R/c 59-61 double tempered<br />

R/c 61-63 triple tempered<br />

R/c 62-64 triple tempered<br />

Ordering Example:<br />

(14) PPSR 375-C300 M2 P.250<br />

A125<br />

A125<br />

A125<br />

A125<br />

A125<br />

A150<br />

A150<br />

A150<br />

A150<br />

A150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

A175<br />

A175<br />

A175<br />

A175<br />

A175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

The principles of <strong>Lane</strong> in-house heat<br />

treatment is to provide quality products<br />

to users with the best combination of<br />

toughness and wear resistance.<br />

OVERALL LENGTH (L)<br />

1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00<br />

A200<br />

A200<br />

A200<br />

A200<br />

A200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

A225<br />

A225<br />

A225<br />

A225<br />

A225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

A250<br />

A250<br />

A250<br />

A250<br />

A250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

<br />

A275<br />

A275<br />

A275<br />

A275<br />

A275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

A300<br />

A300<br />

A300<br />

A300<br />

A300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300

PDWM<br />

P <strong>Punch</strong> S houlder Round<br />

OTHER<br />

P<strong>eerless</strong><br />

Die-section<br />

Wire EDM<br />

Multi-hole<br />

Page R 11-12<br />

CATALOG<br />

NUMBER<br />

PPSR 125<br />

PPSR 187<br />

PPSR 250<br />

PPSR 312<br />

PPSR 375<br />

PPSR 125<br />

PPSR 187<br />

PPSR 250<br />

PPSR 312<br />

PPSR 375<br />

PPSR 437<br />

PPSR 500<br />

PPSR 625<br />

PPSR 750<br />

PPSR 1000<br />

PPSR 125<br />

PPSR 187<br />

PPSR 250<br />

PPSR 312<br />

PPSR 375<br />

PPSR 437<br />

PPSR 500<br />

PPSR 625<br />

PPSR 750<br />

PPSR 1000<br />

PPSR 125<br />

PPSR 187<br />

PPSR 250<br />

PPSR 312<br />

PPSR 375<br />

PPSR 437<br />

PPSR 500<br />

PPSR 625<br />

PPSR 750<br />

PPSR 1000<br />

PPSR 187<br />

PPSR 250<br />

PPSR 312<br />

PPSR 375<br />

PPSR 437<br />

PPSR 500<br />

PPSR 625<br />

PPSR 750<br />

PPSR 1000<br />

<strong>eerless</strong><br />

P<strong>eerless</strong> PRODUCTS;<br />

<br />

Standard or Special,<br />

We Welcome The<br />

Opportunity to Quote!<br />

OVERALL LENGTH (L)<br />

3.25 3.50 3.75 4.00<br />

A325<br />

A325<br />

A325<br />

A325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

A350<br />

A350<br />

A350<br />

A350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

A375<br />

A375<br />

B375<br />

B375<br />

B375<br />

B375<br />

B375<br />

B375<br />

B375<br />

C375<br />

C375<br />

C375<br />

C375<br />

C375<br />

C375<br />

C375<br />

D375<br />

D375<br />

D375<br />

D375<br />

D375<br />

D375<br />

D375<br />

E375<br />

E375<br />

E375<br />

E375<br />

E375<br />

E375<br />

E375<br />

A400<br />

A400<br />

B400<br />

B400<br />

B400<br />

B400<br />

B400<br />

B400<br />

B400<br />

C400<br />

C400<br />

C400<br />

C400<br />

C400<br />

C400<br />

C400<br />

D400<br />

D400<br />

D400<br />

D400<br />

D400<br />

D400<br />

D400<br />

E400<br />

E400<br />

E400<br />

E400<br />

E400<br />

E400<br />

E400<br />

SHANK<br />

DIA. D<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

PEERLESS<br />

BUTTON DIE<br />

SHOULDER<br />

ROUND<br />

PEERLESS<br />

BUTTON DIE<br />

SHOULDER<br />

OBLONG<br />

Page PS23<br />

STRAIGHT BEFORE RADIUS<br />

D-P<br />

2<br />

<br />

PBSR<br />

PBSO <br />

D<br />

SHANK DIA.<br />

.500<br />

.468<br />

.437<br />

.406<br />

.375<br />

.343<br />

.312<br />

.281<br />

.250<br />

.218<br />

.187<br />

.156<br />

.125<br />

.093<br />

.062<br />

0<br />

<br />

ENGINEERING CHANGE?<br />

Need To Add a Round<br />

or Shaped <strong>Punch</strong><br />

and Die Button?<br />

Upstairs or Downstairs,<br />

The change is made easy with<br />

<strong>Lane</strong>'s New Shoulder Retainers.<br />

Page SR 9-10.<br />

.500 RAD<br />

D-P<br />

2<br />

0 .100 .200 .300 .400<br />

SMALLEST<br />

of "P" or "W"<br />

LR<br />

SBR<br />

Calculating usable Straight Before Radius (SBR)<br />

1. Subtract smaller of point size "P" if round or "W"<br />

if shaped from Shank Diameter "D" and divide by 2.<br />

D-P (or "W")<br />

2<br />

2. Locate the D-P total on the horizontal axis<br />

2 at top right of graph.<br />

3. The intersection point of this line at radius establishes<br />

the length of radius, "read on the vertical axis at left.<br />

Your answer is length of Radius (LR).<br />

4. Subtract LR from your desired Point Length "B" to<br />

determine the Straight Before Radius " (SBR).<br />

S B R = "B" - "LR"<br />

Example: D = .750 P = .330 B = .75<br />

D-P<br />

1. 2 = (.750 -.330) ÷ 2 = .210<br />

2. The .210 line intersects the radius at .406<br />

3. B - LR = SBR .75 - .406 = .344 (SBR)<br />

B<br />

®<br />

PS6

PS7<br />

P<strong>eerless</strong> <strong>Punch</strong> Shoulder<br />

+.010<br />

+.005<br />

.188*<br />

L +.020<br />

+.010<br />

POINT LENGTH<br />

.50<br />

Fillet<br />

.01<br />

.02<br />

D<br />

B +.06<br />

-.0<br />

* .125 WHEN D = .1875 OR .1250<br />

.75<br />

®<br />

1.00<br />

1.25<br />

1.50<br />

D + .125<br />

+.0<br />

-.010<br />

+.0004<br />

+.0002<br />

D - .001<br />

Lead-In<br />

.5R Blend<br />

Radius<br />

B<br />

.50<br />

A<br />

.75<br />

B<br />

1.00<br />

C<br />

1.25<br />

D<br />

1.50<br />

E<br />

P<br />

PEERLESS<br />

PUNCH<br />

SHOULDER<br />

OBLONG<br />

+ .0002<br />

P & W Tolerance - .0<br />

P & W TO D .0003<br />

P<br />

CATALOG<br />

NUMBER<br />

PPSO 125<br />

PPSO 187<br />

PPSO 250<br />

PPSO 312<br />

PPSO 375<br />

PPSO 125<br />

PPSO 187<br />

PPSO 250<br />

PPSO 312<br />

PPSO 375<br />

PPSO 437<br />

PPSO 500<br />

PPSO 625<br />

PPSO 750<br />

PPSO 1000<br />

PPSO 125<br />

PPSO 187<br />

PPSO 250<br />

PPSO 312<br />

PPSO 375<br />

PPSO 437<br />

PPSO 500<br />

PPSO 625<br />

PPSO 750<br />

PPSO 1000<br />

PPSO 125<br />

PPSO 187<br />

PPSO 250<br />

PPSO 312<br />

PPSO 375<br />

PPSO 437<br />

PPSO 500<br />

PPSO 625<br />

PPSO 750<br />

PPSO 1000<br />

PPSO 187<br />

PPSO 250<br />

PPSO 312<br />

PPSO 375<br />

PPSO 437<br />

PPSO 500<br />

PPSO 625<br />

PPSO 750<br />

PPSO 1000<br />

<strong>eerless</strong><br />

<br />

PPSO<br />

W<br />

MIN.<br />

W<br />

.062<br />

.062<br />

.062<br />

.062<br />

.080<br />

.062<br />

.062<br />

.062<br />

.062<br />

.080<br />

.109<br />

.125<br />

.235<br />

.235<br />

.235<br />

.062<br />

.062<br />

.062<br />

.093<br />

.109<br />

.109<br />

.125<br />

.235<br />

.235<br />

.235<br />

.093<br />

.093<br />

.093<br />

.093<br />

.125<br />

.141<br />

.141<br />

.235<br />

.235<br />

.235<br />

.125<br />

.125<br />

.125<br />

.125<br />

.172<br />

.172<br />

.235<br />

.235<br />

.235<br />

<strong>Punch</strong> S houlder<br />

PEERLESS<br />

PUNCH<br />

SHOULDER<br />

SQUARE/RECTANGLE<br />

+ .0002<br />

P & W Tolerance - .0<br />

P & W TO D .0003<br />

P<br />

CATALOG<br />

NUMBER<br />

PPSS 125<br />

PPSS 187<br />

PPSS 250<br />

PPSS 312<br />

PPSS 375<br />

PPSS 125<br />

PPSS 187<br />

PPSS 250<br />

PPSS 312<br />

PPSS 375<br />

PPSS 437<br />

PPSS 500<br />

PPSS 625<br />

PPSS 750<br />

PPSS 1000<br />

PPSS 125<br />

PPSS 187<br />

PPSS 250<br />

PPSS 312<br />

PPSS 375<br />

PPSS 437<br />

PPSS 500<br />

PPSS 625<br />

PPSS 750<br />

PPSS 1000<br />

PPSS 125<br />

PPSS 187<br />

PPSS 250<br />

PPSS 312<br />

PPSS 375<br />

PPSS 437<br />

PPSS 500<br />

PPSS 625<br />

PPSS 750<br />

PPSS 1000<br />

PPSS 187<br />

PPSS 250<br />

PPSS 312<br />

PPSS 375<br />

PPSS 437<br />

PPSS 500<br />

PPSS 625<br />

PPSS 750<br />

PPSS 1000<br />

PPSS<br />

W<br />

G<br />

P + W<br />

G must not exceed shank dia.<br />

2<br />

2<br />

G=<br />

.062<br />

.062<br />

.062<br />

.062<br />

.080<br />

.062<br />

.062<br />

.062<br />

.062<br />

.080<br />

.109<br />

.125<br />

.235<br />

.235<br />

.235<br />

.062<br />

.062<br />

.062<br />

.093<br />

.109<br />

.109<br />

.125<br />

.235<br />

.235<br />

.235<br />

.093<br />

.093<br />

.093<br />

.093<br />

.125<br />

.141<br />

.141<br />

.235<br />

.235<br />

.235<br />

.125<br />

.125<br />

.125<br />

.125<br />

.172<br />

.172<br />

.235<br />

.235<br />

.235<br />

<br />

MIN.<br />

W<br />

PEERLESS<br />

PUNCH<br />

SHOULDER<br />

HIGH PRODUCTION<br />

+ .0002<br />

P & W Tolerance - .0<br />

P & W TO D .0003<br />

P<br />

+.0002<br />

-.0000<br />

R.020<br />

CATALOG<br />

NUMBER<br />

PPSH 125<br />

PPSH 187<br />

PPSH 250<br />

PPSH 312<br />

PPSH 375<br />

PPSH 125<br />

PPSH 187<br />

PPSH 250<br />

PPSH 312<br />

PPSH 375<br />

PPSH 437<br />

PPSH 500<br />

PPSH 625<br />

PPSH 750<br />

PPSH 1000<br />

PPSH 125<br />

PPSH 187<br />

PPSH 250<br />

PPSH 312<br />

PPSH 375<br />

PPSH 437<br />

PPSH 500<br />

PPSH 625<br />

PPSH 750<br />

PPSH 1000<br />

PPSH 125<br />

PPSH 187<br />

PPSH 250<br />

PPSH 312<br />

PPSH 375<br />

PPSH 437<br />

PPSH 500<br />

PPSH 625<br />

PPSH 750<br />

PPSH 1000<br />

PPSH 187<br />

PPSH 250<br />

PPSH 312<br />

PPSH 375<br />

PPSH 437<br />

PPSH 500<br />

PPSH 625<br />

PPSH 750<br />

PPSH 1000<br />

O<br />

S<br />

H<br />

=<br />

=<br />

=<br />

<br />

PPSH<br />

W<br />

G<br />

G=[ + .040<br />

(P-.040) 2 + (W-.040) 2 ]<br />

MIN.<br />

W<br />

.062<br />

.062<br />

.062<br />

.062<br />

.080<br />

.062<br />

.062<br />

.062<br />

.062<br />

.080<br />

.109<br />

.125<br />

.235<br />

.235<br />

.235<br />

.062<br />

.062<br />

.062<br />

.093<br />

.109<br />

.109<br />

.125<br />

.235<br />

.235<br />

.235<br />

.093<br />

.093<br />

.093<br />

.093<br />

.125<br />

.141<br />

.141<br />

.235<br />

.235<br />

.235<br />

.125<br />

.125<br />

.125<br />

.125<br />

.172<br />

.172<br />

.235<br />

.235<br />

.235<br />

<br />

"SBR," Straight<br />

before Radius<br />

chart page PS2.<br />

Heads are drawn<br />

to 40-55 Rc.<br />

MAX.<br />

P/G<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

SHANK<br />

DIA. D<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000

MAX<br />

P/G<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1250<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

.1875<br />

.2500<br />

.3125<br />

.3750<br />

.4375<br />

.5000<br />

.6250<br />

.7500<br />

1.0000<br />

P<br />

<strong>eerless</strong><br />

1. Standard rectangular or<br />

square die buttons have a<br />

.007" radius in the corners.<br />

This is consistent with all<br />

manufacturers.<br />

2. This die button corner<br />

radius frequently interferes<br />

with the sharp corners of a<br />

standard rectangular punch,<br />

causing premature failure of<br />

the punch. It causes drag<br />

type burrs at each corner of<br />

the punched hole.<br />

CATALOG<br />

NUMBER<br />

PPS_ O/S/H 125<br />

PPS_ O/S/H 187<br />

PPS_ O/S/H 250<br />

PPS_ O/S/H 312<br />

PPS_ O/S/H 375<br />

PPS_ O/S/H 125<br />

PPS_ O/S/H 187<br />

PPS_ O/S/H 250<br />

PPS_ O/S/H 312<br />

PPS_ O/S/H 375<br />

PPS_ O/S/H 437<br />

PPS_ O/S/H 500<br />

PPS_ O/S/H 625<br />

PPS_ O/S/H 750<br />

PPS_ O/S/H 1000<br />

PPS_ O/S/H 125<br />

PPS_ O/S/H 187<br />

PPS_ O/S/H 250<br />

PPS_ O/S/H 312<br />

PPS_ O/S/H 375<br />

PPS_ O/S/H 437<br />

PPS_ O/S/H 500<br />

PPS_ O/S/H 625<br />

PPS_ O/S/H 750<br />

PPS_ O/S/H 1000<br />

PPS_ O/S/H 125<br />

PPS_ O/S/H 187<br />

PPS_ O/S/H 250<br />

PPS_ O/S/H 312<br />

PPS_ O/S/H 375<br />

PPS_ O/S/H 437<br />

PPS_ O/S/H 500<br />

PPS_ O/S/H 625<br />

PPS_ O/S/H 750<br />

PPS_ O/S/H 1000<br />

PPS_ O/S/H 187<br />

PPS_ O/S/H 250<br />

PPS_ O/S/H 312<br />

PPS_ O/S/H 375<br />

PPS_ O/S/H 437<br />

PPS_ O/S/H 500<br />

PPS_ O/S/H 625<br />

PPS_ O/S/H 750<br />

PPS_ O/S/H 1000<br />

<strong>Punch</strong> S houlder<br />

Suggestions on selecting the High<br />

Production "H" style punch point.<br />

3. The "H" style punch will<br />

eliminate this interference<br />

and greatly increase your<br />

stamping production from<br />

rectangular and square<br />

punches.<br />

4. Your punch life will<br />

increase, down-time<br />

will be reduced, your<br />

average manufacturing<br />

cost-per-stamping will<br />

be lowered.<br />

A125<br />

A125<br />

A125<br />

A125<br />

A125<br />

A150<br />

A150<br />

A150<br />

A150<br />

A150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

A175<br />

A175<br />

A175<br />

A175<br />

A175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

A200<br />

A200<br />

A200<br />

A200<br />

A200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

O<br />

S<br />

H<br />

A225<br />

A225<br />

A225<br />

A225<br />

A225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

=<br />

=<br />

=<br />

The principles of <strong>Lane</strong> in-house heat<br />

treatment is to provide quality products<br />

to users with the best combination of<br />

toughness and wear resistance.<br />

Classified shapes are fully<br />

defined on pages T 5-7<br />

in Technical Section.<br />

Ordering Example:<br />

(14) PPSS 375-C300 M2 P.250 W.187 K4*<br />

180˚<br />

OVERALL LENGTH (L)<br />

1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00<br />

A250<br />

A250<br />

A250<br />

A250<br />

A250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

<br />

A2,<br />

M2,<br />

PS,<br />

90˚<br />

270˚<br />

K2<br />

A275<br />

A275<br />

A275<br />

A275<br />

A275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

R/c 59-61 double tempered<br />

R/c 61-63 triple tempered<br />

R/c 62-64 triple tempered<br />

0˚<br />

180˚<br />

* Radial locking devices for shapes are detailed Pg.T 9-10 Technical Section.<br />

A300<br />

A300<br />

A300<br />

A300<br />

A300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

B300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

C300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

D300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300<br />

E300<br />

90˚<br />

270˚<br />

K3<br />

0˚<br />

A325<br />

A325<br />

A325<br />

A325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

B325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

C325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

D325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

E325<br />

180˚<br />

A350<br />

A350<br />

A350<br />

A350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

B350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

C350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

D350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

E350<br />

90˚<br />

270˚<br />

K4<br />

0˚<br />

A375<br />

A375<br />

B375<br />

B375<br />

B375<br />

B375<br />

B375<br />

B375<br />

B375<br />

C375<br />

C375<br />

C375<br />

C375<br />

C375<br />

C375<br />

C375<br />

D375<br />

D375<br />

D375<br />

D375<br />

D375<br />

D375<br />

D375<br />

E375<br />

E375<br />

E375<br />

E375<br />

E375<br />

E375<br />

E375<br />

®<br />

A400<br />

A400<br />

B400<br />

B400<br />

B400<br />

B400<br />

B400<br />

B400<br />

B400<br />

C400<br />

C400<br />

C400<br />

C400<br />

C400<br />

C400<br />

C400<br />

D400<br />

D400<br />

D400<br />

D400<br />

D400<br />

D400<br />

D400<br />

E400<br />

E400<br />

E400<br />

E400<br />

E400<br />

E400<br />

E400<br />

PS8

P<strong>eerless</strong> <strong>Punch</strong> Shoulder<br />

Angular Pilot<br />

P<br />

* .125 WHEN D = .1250 or .1875<br />

PS9<br />

L +.020<br />

+.010<br />

.188*<br />

Fillet<br />

.01<br />

.02<br />

D<br />

B +.06<br />

-.0<br />

POINT LENGTH B<br />

CATALOG<br />

NUMBER<br />

.50<br />

.50<br />

A<br />

.75<br />

D + .125<br />

1.00<br />

1.25<br />

1.50<br />

®<br />

+.0<br />

-.010<br />

+.0004<br />

+.0002<br />

D - .001<br />

Lead-In<br />

.5R Blend<br />

Radius<br />

.75<br />

B<br />

1.00<br />

C<br />

1.25<br />

D<br />

1.50<br />

E<br />

P<br />

PPSA <br />

PEERLESS<br />

PUNCH<br />

SHOULDER<br />

<strong>eerless</strong><br />

ANGULAR PILOT<br />

* Angular point length is calculated as follows:<br />

.187 diameter and larger = P dia. x 1.2<br />

under .187 diameter = P x 1.5<br />

PPSA 125<br />

PPSA 187<br />

PPSA 250<br />

PPSA 312<br />

PPSA 375<br />

PPSA 125<br />

PPSA 187<br />

PPSA 250<br />

PPSA 312<br />

PPSA 375<br />

PPSA 437<br />

PPSA 500<br />

PPSA 625<br />

PPSA 750<br />

PPSA 1000<br />

PPSA 125<br />

PPSA 187<br />

PPSA 250<br />

PPSA 312<br />

PPSA 375<br />

PPSA 437<br />

PPSA 500<br />

PPSA 625<br />

PPSA 750<br />

PPSA 1000<br />

PPSA 125<br />

PPSA 187<br />

PPSA 250<br />

PPSA 312<br />

PPSA 375<br />

PPSA 437<br />

PPSA 500<br />

PPSA 625<br />

PPSA 750<br />

PPSA 1000<br />

PPSA 187<br />

PPSA 250<br />

PPSA 312<br />

PPSA 375<br />

PPSA 437<br />

PPSA 500<br />

PPSA 625<br />

PPSA 750<br />

PPSA 1000<br />

MIN.<br />

P<br />

.050<br />

.050<br />

.061<br />

.061<br />

.061<br />

.050<br />

.050<br />

.061<br />

.061<br />

.061<br />

.092<br />

.124<br />

.234<br />

.299<br />

.399<br />

.057<br />

.057<br />

.061<br />

.061<br />

.061<br />

.092<br />

.124<br />

.234<br />

.299<br />

.399<br />

.074<br />

.074<br />

.079<br />

.092<br />

.092<br />

.092<br />

.124<br />

.234<br />

.299<br />

.399<br />

.092<br />

.092<br />

.092<br />

.124<br />

.124<br />

.124<br />

.234<br />

.299<br />

.399<br />

5˚ L<br />

<br />

<strong>Punch</strong> S houlder A ngular Pilot<br />

.499<br />

SHANK<br />

DIA. D<br />

.1250<br />

.1870<br />

.2500<br />

.3120<br />

.3750<br />

.1250<br />

.1870<br />

.2500<br />

.3120<br />

.3750<br />

.4370<br />

.5000<br />

.6250<br />

.7500<br />

.1000<br />

.1250<br />

.1870<br />

.2500<br />

.3120<br />

.3750<br />

.4370<br />

.5000<br />

.6250<br />

.7500<br />

.1000<br />

.1250<br />

.1870<br />

.2500<br />

.3120<br />

.3750<br />

.4370<br />

.5000<br />

.6250<br />

.7500<br />

.1000<br />

.1870<br />

.2500<br />

.3120<br />

.3750<br />

.4370<br />

.5000<br />

.6250<br />

.7500<br />

.1000<br />

40˚ INCL.<br />

1.2 P*<br />

.035<br />

.500 R<br />

1.25<br />

A125<br />

A125<br />

A125<br />

A125<br />

A125<br />

A150<br />

A150<br />

A150<br />

A150<br />

A150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

B150<br />

.030<br />

.020 R<br />

1.50 1.75<br />

A175<br />

A175<br />

A175<br />

A175<br />

A175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

B175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

C175<br />

A2, R/c 59-61 double tempered<br />

M2, R/c 61-63 triple tempered<br />

PS, R/c 62-64 triple tempered<br />

P Tolerance<br />

P TO D .0003<br />

LENGTH (L)<br />

2.00 2.25 2.50 2.75<br />

A200<br />

A200<br />

A200<br />

A200<br />

A200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

B200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

C200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

D200<br />

A225<br />

A225<br />

A225<br />

A225<br />

A225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

B225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

C225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

D225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

E225<br />

A250<br />

A250<br />

A250<br />

A250<br />

A250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

B250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

C250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

D250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

E250<br />

+ .0002<br />

- .0000<br />

Altered Length, (AL)<br />

Length (L) may be altered<br />

at no additional cost within<br />

standard catalog range.<br />

Specify (AL) when ordering.<br />

See View:<br />

(L) does not include point.<br />

A275<br />

A275<br />

A275<br />

A275<br />

A275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

B275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

C275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

D275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />

E275<br />