- Page 3 and 4:

ahp.book 3.0 BZN 250 1/60 ahp.plus

- Page 6 and 7:

ahp.plus Schnelllieferprogramm Für

- Page 9 and 10:

ahp informiert. 1 Grundlegendes zu

- Page 11:

2.7 Zentrierbund . . . . . . . . .

- Page 14 and 15:

10 Rundblockzylinder (RZ) Rundblock

- Page 16 and 17:

1.3 Allgemeine Berechnungen ! 12 Um

- Page 18 and 19:

14 Knickfestigkeit Zur richtigen Di

- Page 20 and 21:

1.7 Betriebstemperatur ! 16 Die Obe

- Page 22 and 23:

1.11 Einfluss äußerer Kräfte ! 1

- Page 24 and 25:

1.14 Anwendungssituationen von Hydr

- Page 26 and 27: 22 Lecköl Als Sonderkonstruktion g

- Page 28 and 29: 2 Zylinder Merkmale 2.1 Bauteildefi

- Page 30 and 31: 2.4 Hydraulikzylinder mit Besonderh

- Page 32 and 33: 28 Mehrstellungszylinder Der Mehrst

- Page 34 and 35: 2.7 Zentrierbund 2.8 Nut ! 30 Wird

- Page 36 and 37: Tipp 2.10 Korrosionsbeständige Aus

- Page 38 and 39: ! 3.2 Magnetfeldsensoren 34 Magnetf

- Page 40 and 41: 4 Betriebs- und Wartungshinweise 4.

- Page 42 and 43: ! 38 Montage der Stangendichtung Be

- Page 44 and 45: ! Tipp ! 40 Montage von Führungsb

- Page 46 and 47: 4.5 Montage und Inbetriebnahme von

- Page 48 and 49: 44 Einstellbare induktive Näherung

- Page 50 and 51: 46 8 10 1,51 1,23 10 12 2,36 2,01 1

- Page 52 and 53: STZ 250 40-63 2 80-100 125-200 RZ 5

- Page 55 and 56: ahp informiert. 1 Basic information

- Page 57: 2.7 Centering collar . . . . . . .

- Page 60 and 61: 56 Circular block cylinder (RZ) Cir

- Page 62 and 63: 1.3 General calculations ! 58 Conve

- Page 64 and 65: 60 Buckling strength Proper dimensi

- Page 66 and 67: 1.8 Air in the hydraulic system 62

- Page 68 and 69: 1.11 Effect of external forces ! 64

- Page 70 and 71: 1.14 Application situations for hyd

- Page 72 and 73: 68 Leakage oil As a special design

- Page 74 and 75: 2 Cylinder parameters 2.1 Component

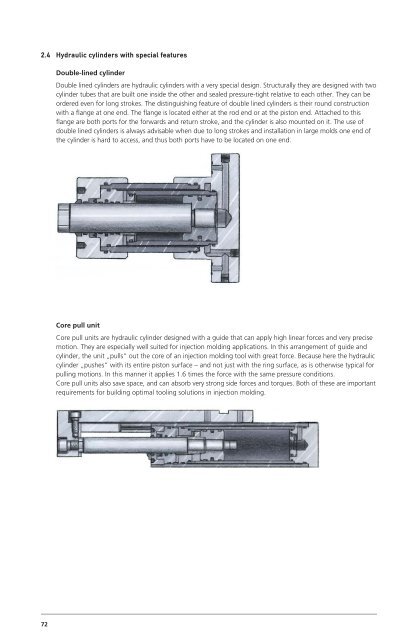

- Page 78 and 79: 74 Multiposition cylinders Multipos

- Page 80 and 81: 2.7 Centering collar 76 If the cyli

- Page 82 and 83: Tip 2.10 Corrosion-resistant design

- Page 84 and 85: ! 3.2 Magnetic field sensors 80 Mag

- Page 86 and 87: 4 Operating and maintenance instruc

- Page 88 and 89: ! 84 Installing the rod seal If the

- Page 90 and 91: ! Tip ! 86 Installing the guide rin

- Page 92 and 93: 4.5 Assembly and commissioning of h

- Page 94 and 95: 90 Adjustable inductive proximity s

- Page 96 and 97: 5 Cylinder fi nder 92 8 10 10 12 12

- Page 98 and 99: STZ 250 40-63 2 80-100 125-200 RZ 5

- Page 101 and 102: ahp informiert. 1 Notions fondament

- Page 103 and 104: 2.7 Centrage . . . . . . . . . . .

- Page 105 and 106: 1.1 Explications relatives aux diff

- Page 107 and 108: Notions fondamentales concernant le

- Page 109 and 110: ! Info Pour les charges de poussée

- Page 111 and 112: ! 1.4 Pressions dans les vérins hy

- Page 113 and 114: 1.10 Mode d‘action de l‘amortis

- Page 115 and 116: ! Les HFC sont ce que l‘on appell

- Page 117 and 118: ! Info La mise en place de diviseur

- Page 119 and 120: ! Pour obtenir une durée de vie la

- Page 121 and 122: 2.2 Qualité de finition des tiges

- Page 123 and 124: ! Vérin double effet - poussée Il

- Page 125 and 126: ! Info Conclusion Les vérins hydra

- Page 127 and 128:

2.9 Extrémités de tige de piston

- Page 129 and 130:

3 Capteurs et systèmes d‘interro

- Page 131 and 132:

3.3 Capteurs mécaniques Les princi

- Page 133 and 134:

! ! Info Lorsque tous les travaux d

- Page 135 and 136:

Info ! Montage du joint de piston L

- Page 137 and 138:

4.4 Obtenir des pièces de rechange

- Page 139 and 140:

! 4.6 Réglage de l‘amortissement

- Page 141 and 142:

! 4.8 Consignes générales de séc

- Page 143 and 144:

Vérin-bloc BZ 500 BZ 320 BRB 250 B

- Page 145 and 146:

Fichier Unité tire-noyau KZE 251 V

- Page 147 and 148:

ahp produziert. 1 Blockzylinder Blo

- Page 149 and 150:

Blockzylinder Block cylinder Vérin

- Page 151 and 152:

Typ Type Type BZ BZ 250 BZN BZN 250

- Page 153 and 154:

36 01 02 04 05 ... .9 Typ Type Type

- Page 155 and 156:

N m Z G4 Mit Nut With keyway Avec r

- Page 157 and 158:

Optionen Options Options V E… N m

- Page 159 and 160:

Nenndruck, statisch Nominal pressur

- Page 161 and 162:

Nenndruck, statisch Nominal pressur

- Page 163 and 164:

Nenndruck, statisch Nominal pressur

- Page 165 and 166:

Nenndruck, statisch Nominal pressur

- Page 167 and 168:

Nenndruck, statisch Nominal pressur

- Page 169 and 170:

Nenndruck, statisch Nominal pressur

- Page 171 and 172:

Nenndruck, statisch Nominal pressur

- Page 173 and 174:

Nenndruck, statisch Nominal pressur

- Page 175 and 176:

Nenndruck, statisch Nominal pressur

- Page 177 and 178:

Nenndruck, statisch Nominal pressur

- Page 179 and 180:

BZ 500 BZ 500.50/32 BZ 500.63/40 BZ

- Page 181 and 182:

Optionen Options Options V E3 G4 Si

- Page 183 and 184:

Nenndruck, statisch Nominal pressur

- Page 185 and 186:

Optionen Options Options V E… N m

- Page 187 and 188:

Nenndruck, statisch Nominal pressur

- Page 189 and 190:

Nenndruck, statisch Nominal pressur

- Page 191 and 192:

Nenndruck, statisch Nominal pressur

- Page 193 and 194:

Nenndruck, statisch Nominal pressur

- Page 195 and 196:

Nenndruck, statisch Nominal pressur

- Page 197 and 198:

Nenndruck, statisch Nominal pressur

- Page 199 and 200:

Nenndruck, statisch Nominal pressur

- Page 201 and 202:

Nenndruck, statisch Nominal pressur

- Page 203 and 204:

Nenndruck, statisch Nominal pressur

- Page 205 and 206:

BZN 500.06 BZN 500.36 201 206 40 44

- Page 207 and 208:

BZN 500.50/32.N20 Hub Stroke Course

- Page 209 and 210:

Optionen Options Options V E3 G4 Si

- Page 211 and 212:

Nenndruck, statisch Nominal pressur

- Page 213 and 214:

Mit Magnetfeld-Sensoren With magnet

- Page 215 and 216:

Wegmesssysteme für Blockzylinder (

- Page 217 and 218:

Nenndruck, statisch Nominal pressur

- Page 219 and 220:

Nenndruck, statisch Nominal pressur

- Page 221 and 222:

Nenndruck, statisch Nominal pressur

- Page 223 and 224:

Nenndruck, statisch Nominal pressur

- Page 225 and 226:

Nenndruck, statisch Nominal pressur

- Page 227 and 228:

Nenndruck, statisch Nominal pressur

- Page 229 and 230:

MBZ 160.32/20 Hub Stroke Course 10

- Page 231 and 232:

MBZ 160 MBZ 160.50/32 MBZ 160.63/40

- Page 233 and 234:

Schalterposition Position of switch

- Page 235 and 236:

Nenndruck, statisch Nominal pressur

- Page 237 and 238:

Nenndruck, statisch Nominal pressur

- Page 239 and 240:

Nenndruck, statisch Nominal pressur

- Page 241 and 242:

Nenndruck, statisch Nominal pressur

- Page 243 and 244:

Nenndruck, statisch Nominal pressur

- Page 245 and 246:

Nenndruck, statisch Nominal pressur

- Page 247 and 248:

Optionen Options Options V E... H20

- Page 249 and 250:

Nenndruck, statisch Nominal pressur

- Page 251 and 252:

Nenndruck, statisch Nominal pressur

- Page 253 and 254:

Optionen Options Options BRB / BRBN

- Page 255 and 256:

Nenndruck, statisch Nominal pressur

- Page 257 and 258:

Nenndruck, statisch Nominal pressur

- Page 259 and 260:

Nenndruck, statisch Nominal pressur

- Page 261 and 262:

Nenndruck, statisch Nominal pressur

- Page 263 and 264:

Optionen Options Options V E... N m

- Page 265 and 266:

Nenndruck, statisch Nominal pressur

- Page 267 and 268:

Nenndruck, statisch Nominal pressur

- Page 269 and 270:

Nenndruck, statisch Nominal pressur

- Page 271 and 272:

Nenndruck, statisch Nominal pressur

- Page 273 and 274:

Nenndruck, statisch Nominal pressur

- Page 275 and 276:

Nenndruck, statisch Nominal pressur

- Page 277 and 278:

Dichtsatz komplett Seal kit complet

- Page 279 and 280:

Dichtsatz komplett Seal kit complet

- Page 281 and 282:

Verschraubung komplett mit Dichtung

- Page 283 and 284:

Ersatzschalter Replacement sensor D

- Page 285 and 286:

Ersatzschalter Replacement sensor D

- Page 287 and 288:

1/139

- Page 289 and 290:

Stanzzylinder Stamping cylinder Vé

- Page 291 and 292:

Bauform Style Forme 01 02 03 04 05

- Page 293 and 294:

N m Z Mit Nut With keyway Avec rain

- Page 295 and 296:

Nenndruck, statisch Nominal pressur

- Page 297 and 298:

Nenndruck, statisch Nominal pressur

- Page 299 and 300:

2/11

- Page 301 and 302:

Rundblockzylinder Circular block cy

- Page 303 and 304:

Bauform Style Forme 3/4 01 05 Ab La

- Page 305 and 306:

Nenndruck, statisch Nominal pressur

- Page 307 and 308:

Nenndruck, statisch Nominal pressur

- Page 309 and 310:

Nenndruck, statisch Nominal pressur

- Page 311 and 312:

Nenndruck, statisch Nominal pressur

- Page 313 and 314:

RZ 500.63/40 Hub Stroke Course 30 6

- Page 315 and 316:

Verschraubung komplett mit Dichtung

- Page 317 and 318:

Schiebereinheit Push unit Pousseur

- Page 319 and 320:

Typ Type Type BSE BSE XL BSEP ZSE Z

- Page 321 and 322:

Ausführung Mode Mode Mit Führungs

- Page 323 and 324:

Schalterdaten Switch data Caractér

- Page 325 and 326:

Nenndruck, statisch Nominal pressur

- Page 327 and 328:

Nenndruck, statisch Nominal pressur

- Page 329 and 330:

Nenndruck, statisch Nominal pressur

- Page 331 and 332:

Nenndruck, statisch Nominal pressur

- Page 333 and 334:

Nenndruck, statisch Nominal pressur

- Page 335 and 336:

Nenndruck, statisch Nominal pressur

- Page 337 and 338:

Nenndruck, statisch Nominal pressur

- Page 339 and 340:

Nenndruck, statisch Nominal pressur

- Page 341 and 342:

Nenndruck, statisch Nominal pressur

- Page 343 and 344:

BSE 250 BSE 250.50/32 BSE 250.63/40

- Page 345 and 346:

Bauform Style Forme 1 2 1 2 201 V A

- Page 347 and 348:

Nenndruck, statisch Nominal pressur

- Page 349 and 350:

Dichtsatz komplett Seal kit complet

- Page 351 and 352:

4/35

- Page 353 and 354:

Dichtsatz komplett Seal kit complet

- Page 355 and 356:

Verschraubung komplett mit Dichtung

- Page 357 and 358:

Standardzylinder Standard cylinder

- Page 359 and 360:

Typ Type Type UZ 100 * UZN 100 HZ 1

- Page 361 and 362:

Funktionsarten Operation mode Mode

- Page 363 and 364:

M1 M2 M T Kolbenstange mit Innengew

- Page 365 and 366:

Position der Näherungsschalter, D

- Page 367 and 368:

5/11

- Page 369 and 370:

Nenndruck, statisch Nominal pressur

- Page 371 and 372:

Nenndruck, statisch Nominal pressur

- Page 373 and 374:

Nenndruck, statisch Nominal pressur

- Page 375 and 376:

Nenndruck, statisch Nominal pressur

- Page 377 and 378:

Nenndruck, statisch Nominal pressur

- Page 379 and 380:

Nenndruck, statisch Nominal pressur

- Page 381 and 382:

Nenndruck, statisch Nominal pressur

- Page 383 and 384:

Nenndruck, statisch Nominal pressur

- Page 385 and 386:

Nenndruck, statisch Nominal pressur

- Page 387 and 388:

Nenndruck, statisch Nominal pressur

- Page 389 and 390:

Nenndruck, statisch Nominal pressur

- Page 391 and 392:

Nenndruck, statisch Nominal pressur

- Page 393 and 394:

Nenndruck, statisch Nominal pressur

- Page 395 and 396:

Nenndruck, statisch Nominal pressur

- Page 397 and 398:

Nenndruck, statisch Nominal pressur

- Page 399 and 400:

Nenndruck, statisch Nominal pressur

- Page 401 and 402:

Nenndruck, statisch Nominal pressur

- Page 403 and 404:

Nenndruck, statisch Nominal pressur

- Page 405 and 406:

Nenndruck, statisch Nominal pressur

- Page 407 and 408:

Nenndruck, statisch Nominal pressur

- Page 409 and 410:

Nenndruck, statisch Nominal pressur

- Page 411 and 412:

Nenndruck, statisch Nominal pressur

- Page 413 and 414:

Nenndruck, statisch Nominal pressur

- Page 415 and 416:

Nenndruck, statisch Nominal pressur

- Page 417 and 418:

Nenndruck, statisch Nominal pressur

- Page 419 and 420:

Nenndruck, statisch Nominal pressur

- Page 421 and 422:

Nenndruck, statisch Nominal pressur

- Page 423 and 424:

Nenndruck, statisch Nominal pressur

- Page 425 and 426:

Nenndruck, statisch Nominal pressur

- Page 427 and 428:

Nenndruck, statisch Nominal pressur

- Page 429 and 430:

Nenndruck, statisch Nominal pressur

- Page 431 and 432:

Nenndruck, statisch Nominal pressur

- Page 433 and 434:

Nenndruck, statisch Nominal pressur

- Page 435 and 436:

Nenndruck, statisch Nominal pressur

- Page 437 and 438:

Nenndruck, statisch Nominal pressur

- Page 439 and 440:

Optionen Options Options V E… BAO

- Page 441 and 442:

Grundlagen Basic principles Princip

- Page 443 and 444:

Nenndruck, statisch Nominal pressur

- Page 445 and 446:

Nenndruck, statisch Nominal pressur

- Page 447 and 448:

Nenndruck, statisch Nominal pressur

- Page 449 and 450:

Dichtsatz komplett Seal kit complet

- Page 451 and 452:

Dichtsatz komplett Seal kit complet

- Page 453 and 454:

Dichtsatz komplett Seal kit complet

- Page 455 and 456:

Dichtsatz komplett Seal kit complet

- Page 457 and 458:

Spare parts MHZ 160 Pièces de rech

- Page 459 and 460:

Normzylinder DIN standard cylinder

- Page 461 and 462:

Befestigungsarten Mounting modes Mo

- Page 463 and 464:

Lage der Anschlüsse Position of co

- Page 465 and 466:

Nenndruck, statisch Nominal pressur

- Page 467 and 468:

Nenndruck, statisch Nominal pressur

- Page 469 and 470:

Nenndruck, statisch Nominal pressur

- Page 471 and 472:

Nenndruck, statisch Nominal pressur

- Page 473 and 474:

Nenndruck, statisch Nominal pressur

- Page 475 and 476:

Dichtsatz komplett Seal kit complet

- Page 477 and 478:

Hydraulikzylinder mit äußerer Fü

- Page 479 and 480:

Funktionsarten Operation mode Mode

- Page 481 and 482:

Nenndruck Nominal pressure Pression

- Page 483 and 484:

7/7

- Page 485 and 486:

Kurzhubzylinder Short-stroke cylind

- Page 487 and 488:

Typ Type Type WKHZ KHZ WKHZ Seite P

- Page 489 and 490:

Nenndruck, statisch Nominal pressur

- Page 491 and 492:

Schnelllieferprogramm KHZ und WKHZ

- Page 493 and 494:

Verschraubung komplett mit Dichtung

- Page 495 and 496:

8/11

- Page 497 and 498:

Einschraubzylinder Screw-in cylinde

- Page 499 and 500:

Funktionsarten Operation modes Mode

- Page 501 and 502:

Nenndruck, statisch Nominal pressur

- Page 503 and 504:

9/7

- Page 505 and 506:

Kernzugeinheit Core pull unit Unit

- Page 507 and 508:

Typ Type Type KZE KZEP 204 V PR PL

- Page 509 and 510:

Zulässiges Drehmoment [Nm] Permitt

- Page 511 and 512:

Nenndruck, statisch Nominal pressur

- Page 513 and 514:

Ersatzschalter Replacement Sensor D

- Page 515 and 516:

Flanschzylinder Flanged cylinder V

- Page 517 and 518:

Bauform Style Forme 01 Ab Lager Fro

- Page 519 and 520:

Nenndruck, statisch Nominal pressur

- Page 521 and 522:

Verschraubung komplett mit Dichtung

- Page 523 and 524:

Doppelrohrzylinder Double-lined cyl

- Page 525 and 526:

Bauform Style Forme 05 15 12 02 Fun

- Page 527 and 528:

Nenndruck, statisch Nominal pressur

- Page 529 and 530:

Nenndruck, statisch Nominal pressur

- Page 531 and 532:

12/9

- Page 533 and 534:

Spannelemente Clamping elements El

- Page 535 and 536:

Typ Type Type BZK 250 BZF 500 SZ 25

- Page 537 and 538:

Nenndruck, statisch Nominal pressur

- Page 539 and 540:

Nenndruck, statisch Nominal pressur

- Page 541 and 542:

Verschraubung komplett mit Dichtung

- Page 543 and 544:

13/11

- Page 545 and 546:

Drehantrieb Rotary drive unit Servo

- Page 547 and 548:

Funktionsarten Operation modes Mode

- Page 549 and 550:

Nenndruck, statisch Nominal pressur

- Page 551 and 552:

ahp.spezial 15/1 15

- Page 553 and 554:

Mehrstellungszylinder Der Mehrstell

- Page 555 and 556:

Zweikraftzylinder - ziehend Bei die

- Page 557 and 558:

Zubehör Accessories Accessoires 16

- Page 559 and 560:

Kupplung Coupling Accouplement Arti

- Page 561 and 562:

Schutzrohr Protection tube Tube pro

- Page 563 and 564:

018883 GEG. M16 . 20 Artikelnummer

- Page 565 and 566:

Lagerbock LB-LD Bearing pedestals L

- Page 567 and 568:

Bolzen BO-PP Bolts BO-PP Axes de fi

- Page 569 and 570:

Gelenk RC Joint RC Articulation RC

- Page 571 and 572:

Haltewinkel Fixation angle Equerre

- Page 573 and 574:

Artikelnummer Part number Numéro d

- Page 575 and 576:

Abb. A Abb. B 021701 156897 021699

- Page 577 and 578:

Schaltertester Switch tester Testeu

- Page 579 and 580:

28 B A 80 132 132 M8 Schalter Ansch

- Page 581:

Einmaulschlüssel (passend für AHP

- Page 584:

ahp.international North America Eur