Tr pdf bixcut-brochure

Tr pdf bixcut-brochure

Tr pdf bixcut-brochure

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

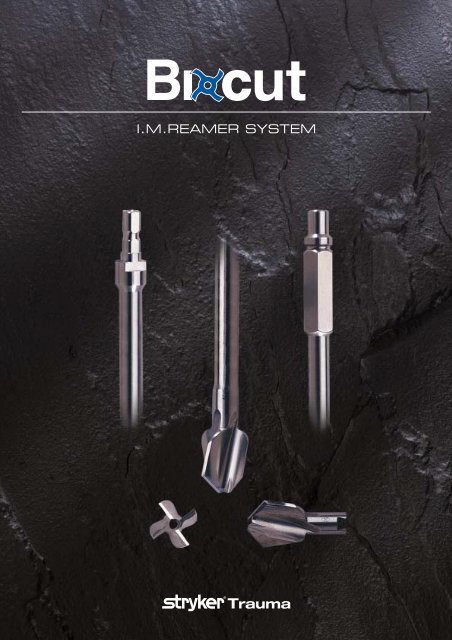

I.M.REAMER SYSTEM

There are two answers<br />

to the reaming question.<br />

This is one...<br />

Pressure Bone Feed Reamer, Shaft and<br />

Increase Marrow Rate Cutting Flutes Ringshaped Gap<br />

The other is .<br />

Recent studies have demonstrated that the pressures<br />

developed within the intramedullary cavity through<br />

the introduction of unreamed IM nails can be far<br />

greater than those developed during reaming – but<br />

that this depends very much upon the design of the<br />

reamer.<br />

After a three year development programme involving<br />

several universities, the factors that determine the<br />

pressures and temperatures developed during reaming<br />

were clearly established. These principles were then<br />

applied to the development of advanced reamers that<br />

demonstrate significantly better performance than the<br />

best of previous designs.<br />

Pressure<br />

Reamer Ø14 mm<br />

Clearance area = 59% of<br />

cross section<br />

10<br />

bar<br />

1.0<br />

Effect of Cutting Flutes<br />

Typical<br />

Standard<br />

Reamer<br />

Complete range of modular<br />

and fixed-head reamers to<br />

match surgeon preference<br />

and optimize OR efficiency,<br />

presented in fullysterilizable<br />

cases<br />

Typical Standard<br />

Reamer Ø14 mm<br />

Clearance area = 32% of<br />

cross section<br />

Reamer Ø14<br />

Other Parameters Constant<br />

0.1<br />

0 25 32 50 59 75 % 100<br />

Relative Area of Reamer<br />

Forward- and side-cut<br />

combination produce<br />

material removal and<br />

clearance

ting face<br />

s efficient<br />

rapid<br />

Large clearance rate resulting from reduced<br />

number of reamer blades coupled with reduced<br />

length of reamer head to give effective relief of<br />

pressure and efficient removal of material<br />

Double-wound shaft transmits torque effectively<br />

and with high reliability<br />

Low-friction surface finish aids rapid debris<br />

clearance<br />

Cutting flute geometry optimized to ensure<br />

low pressure generation<br />

Smaller, 6 and 8 mm shaft<br />

diameters significantly reduce<br />

I.M. pressure<br />

Modular Fixed Head Fixed Head<br />

Head AO-fitting Modified <strong>Tr</strong>inkle fitting<br />

Diameter Cat.no. Cat.no. Length Cat.no. Length<br />

7.5 Fixed Head only 0225 - 6075 480 mm 0227 - 6075 480 mm<br />

8.0 Fixed Head only 0225 - 6080 480 mm 0227 - 6080 480 mm<br />

8.5 Fixed Head only 0225 - 6085 480 mm 0227 - 6085 480 mm<br />

9.0 Fixed Head only 0225 - 6090 480 mm 0227 - 6090 480 mm<br />

9.5 0226 - 3095 0225 - 6095 480 mm 0227 - 6095 480 mm<br />

10.0 0226 - 3100 0225 - 6100 480 mm 0227 - 6100 480 mm<br />

10.5 0226 - 3105 0225 - 6105 480 mm 0227 - 6105 480 mm<br />

11.0 0226 - 3110 0225 - 6110 480 mm 0227 - 6110 480 mm<br />

11.5 0226 - 3115 0225 - 8115 480 mm 0227 - 8115 480 mm<br />

12.0 0226 - 3120 0225 - 8120 480 mm 0227 - 8120 480 mm<br />

12.5 0226 - 3127 0225 - 8127 480 mm 0227 - 8127 480 mm<br />

13.0 0226 - 3130 0225 - 8130 480 mm 0227 - 8130 480 mm<br />

13.5 0226 - 3135 0225 - 8135 480 mm 0227 - 8135 480 mm<br />

14.0 0226 - 3140 0225 - 8140 480 mm 0227 - 8140 480 mm<br />

14.5 0226 - 3145 0225 - 8145 480 mm 0227 - 8145 480 mm<br />

15.0 0226 - 3150 0225 - 8150 480 mm 0227 - 8150 480 mm<br />

15.5 0226 - 3155 0225 - 8155 480 mm 0227 - 8155 480 mm<br />

16.0 0226 - 3160 0225 - 8160 480 mm 0227 - 8160 480 mm<br />

16.5 0226 - 3165 0225 - 8165 480 mm 0227 - 8165 480 mm<br />

17.0 0226 - 3170 0225 - 8170 480 mm 0227 - 8170 480 mm<br />

17.5 0226 - 3175 0225 - 8175 480 mm 0227 - 8175 480 mm<br />

18.0 0226 - 3180 0225 - 8180 480 mm 0227 - 8180 480 mm<br />

Modular Shaft, AO-fitting 0226 - 3000 480 mm<br />

Modular Shaft, Mod. trinkle fitting 0227 - 3000 480 mm<br />

Box, Fixed Head 0225 - 8000<br />

Box, Modular Head 0225 - 6000

© 2000 Stryker ® Corporation. All rights reserved. Printed in Germany.<br />

Stryker ® and Gamma ® logos are registered trademarks of the Stryker ® Corporation.<br />

To ensure the best quality of its products and their improvements<br />

Stryker ® reserves the right to modify all or part of their products.<br />

Caution: Federal law (U.S.A.) restricts this device<br />

to sale by or on the order of a licensed physician.<br />

The <strong>Tr</strong>ochanteric Gamma ® Locking Nail and the original Long Gamma<br />

® Locking Nail are made of Orthinox ® and have been designed by<br />

surgeons. Combining the strength and biomechanical advantages of<br />

the existing Gamma ® family they are the Golden standard for proximal<br />

femoral fractures with more than 500.000 treatments worldwide.<br />

I.C.NAIL<br />

The IC-Nail system is the realization of superior biomechanical<br />

intramedullary stabilization using small caliber, high tensile strength<br />

implants for internal fixation of long bones. Femoral and tibial<br />

implants offers three types of locking including active controlled<br />

intersegmentary compression in cases that are axially stable.<br />

More than 1.000.000 Grosse & Kempf locking nails have been<br />

implanted since its introduction in 1974. A development of the<br />

original intramedullary principles presented by Prof. Gerhard<br />

Küntscher, the femoral and tibial system provides the established<br />

advantages of closed operating technique and undisturbed callus<br />

formation using a sophisticated instrument system.<br />

For retrograde femoral nailing the Supracondylar Nail is the<br />

specialised implant. It is made of Orthinox ® and features a superior<br />

biomechanical stability. Unique to the short SCN is the locking of all<br />

screws via the target device. The design of the condyle screws allow<br />

for interfragmentary compression.<br />

METAIZEAU<br />

Since more than 10 years children from all over the world have<br />

been treated successfully using the Metaizeau paediatric nailing<br />

system. The main advantages of the system are: Simple and fast<br />

technique, closed reduction discharge from hospital at day 4–6<br />

and minimal disturbance of bone growth. The nail can be<br />

adapted to the patient and guarantees a best fit for every case.<br />

I.M. SAW<br />

The I.M. Saw is suitable for closed osteotomies of the femur and<br />

tibia in all cases which allow the use of intramedullary nails for<br />

fragment fixation. Closed osteotomies with subsequent fragment<br />

fixation are indicated for correction of rotational deformities,<br />

angular deformities along the axis and lengthening and shortening<br />

procedures.<br />

MANUFACTURER:<br />

Stryker ® <strong>Tr</strong>auma GmbH<br />

Prof.-Küntscher-Strasse 1–5<br />

D-24232 Schönkirchen<br />

Germany<br />

stryker.europe@<br />

emea.strykercorp.com<br />

REF NO: B0100001<br />

© 2000 Stryker ® Corporation. All rights reserved.