BioSciences - Polysciences, Inc.

BioSciences - Polysciences, Inc.

BioSciences - Polysciences, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

326<br />

Electronic Adhesives & Encapsulants<br />

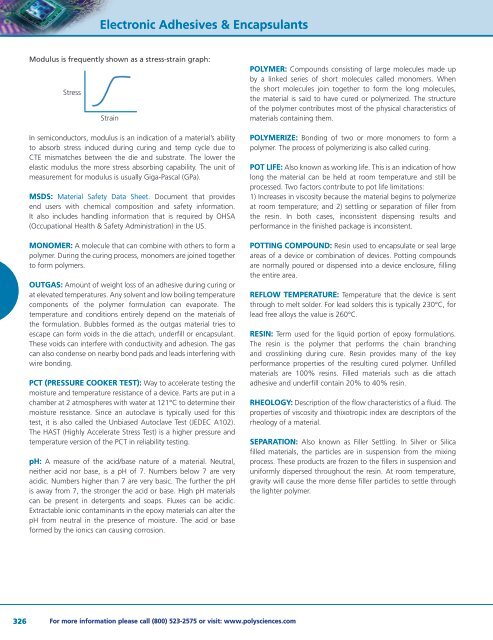

Modulus is frequently shown as a stress-strain graph:<br />

Stress<br />

Strain<br />

In semiconductors, modulus is an indication of a material’s ability<br />

to absorb stress induced during curing and temp cycle due to<br />

CTE mismatches between the die and substrate. The lower the<br />

elastic modulus the more stress absorbing capability. The unit of<br />

measurement for modulus is usually Giga-Pascal (GPa).<br />

MSDS: Material Safety Data Sheet. Document that provides<br />

end users with chemical composition and safety information.<br />

It also includes handling information that is required by OHSA<br />

(Occupational Health & Safety Administration) in the US.<br />

MONOMER: A molecule that can combine with others to form a<br />

polymer. During the curing process, monomers are joined together<br />

to form polymers.<br />

OUTGAS: Amount of weight loss of an adhesive during curing or<br />

at elevated temperatures. Any solvent and low boiling temperature<br />

components of the polymer formulation can evaporate. The<br />

temperature and conditions entirely depend on the materials of<br />

the formulation. Bubbles formed as the outgas material tries to<br />

escape can form voids in the die attach, underfill or encapsulant.<br />

These voids can interfere with conductivity and adhesion. The gas<br />

can also condense on nearby bond pads and leads interfering with<br />

wire bonding.<br />

PCT (PRESSURE COOKER TEST): Way to accelerate testing the<br />

moisture and temperature resistance of a device. Parts are put in a<br />

chamber at 2 atmospheres with water at 121°C to determine their<br />

moisture resistance. Since an autoclave is typically used for this<br />

test, it is also called the Unbiased Autoclave Test (JEDEC A102).<br />

The HAST (Highly Accelerate Stress Test) is a higher pressure and<br />

temperature version of the PCT in reliability testing.<br />

pH: A measure of the acid/base nature of a material. Neutral,<br />

neither acid nor base, is a pH of 7. Numbers below 7 are very<br />

acidic. Numbers higher than 7 are very basic. The further the pH<br />

is away from 7, the stronger the acid or base. High pH materials<br />

can be present in detergents and soaps. Fluxes can be acidic.<br />

Extractable ionic contaminants in the epoxy materials can alter the<br />

pH from neutral in the presence of moisture. The acid or base<br />

formed by the ionics can causing corrosion.<br />

For more information please call (800) 523-2575 or visit: www.polysciences.com<br />

POLYMER: Compounds consisting of large molecules made up<br />

by a linked series of short molecules called monomers. When<br />

the short molecules join together to form the long molecules,<br />

the material is said to have cured or polymerized. The structure<br />

of the polymer contributes most of the physical characteristics of<br />

materials containing them.<br />

POLYMERIZE: Bonding of two or more monomers to form a<br />

polymer. The process of polymerizing is also called curing.<br />

POT LIFE: Also known as working life. This is an indication of how<br />

long the material can be held at room temperature and still be<br />

processed. Two factors contribute to pot life limitations:<br />

1) <strong>Inc</strong>reases in viscosity because the material begins to polymerize<br />

at room temperature; and 2) settling or separation of filler from<br />

the resin. In both cases, inconsistent dispensing results and<br />

performance in the finished package is inconsistent.<br />

POTTING COMPOUND: Resin used to encapsulate or seal large<br />

areas of a device or combination of devices. Potting compounds<br />

are normally poured or dispensed into a device enclosure, filling<br />

the entire area.<br />

REFLOW TEMPERATURE: Temperature that the device is sent<br />

through to melt solder. For lead solders this is typically 230°C, for<br />

lead free alloys the value is 260°C.<br />

RESIN: Term used for the liquid portion of epoxy formulations.<br />

The resin is the polymer that performs the chain branching<br />

and crosslinking during cure. Resin provides many of the key<br />

performance properties of the resulting cured polymer. Unfilled<br />

materials are 100% resins. Filled materials such as die attach<br />

adhesive and underfill contain 20% to 40% resin.<br />

RHEOLOGY: Description of the flow characteristics of a fluid. The<br />

properties of viscosity and thixotropic index are descriptors of the<br />

rheology of a material.<br />

SEPARATION: Also known as Filler Settling. In Silver or Silica<br />

filled materials, the particles are in suspension from the mixing<br />

process. These products are frozen to the fillers in suspension and<br />

uniformly dispersed throughout the resin. At room temperature,<br />

gravity will cause the more dense filler particles to settle through<br />

the lighter polymer.