Technical Manual NASON SELECTPRIME™ 421 ... - Auto Paint Plus

Technical Manual NASON SELECTPRIME™ 421 ... - Auto Paint Plus

Technical Manual NASON SELECTPRIME™ 421 ... - Auto Paint Plus

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

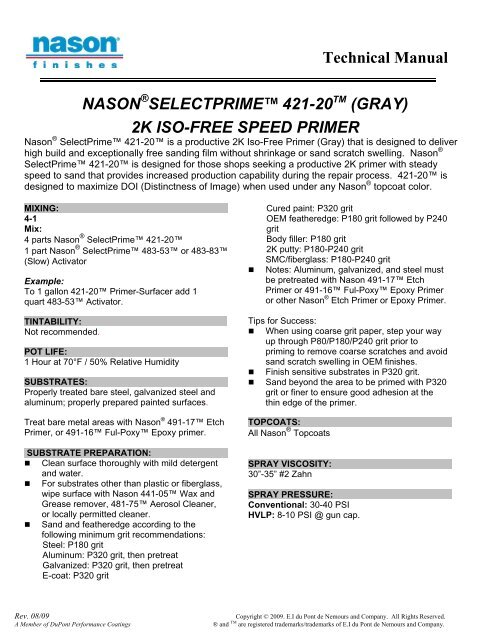

<strong>Technical</strong> <strong>Manual</strong><br />

<strong>NASON</strong> ® SELECTPRIME <strong>421</strong>-20 TM (GRAY)<br />

2K ISO-FREE SPEED PRIMER<br />

Nason ® SelectPrime <strong>421</strong>-20 is a productive 2K Iso-Free Primer (Gray) that is designed to deliver<br />

high build and exceptionally free sanding film without shrinkage or sand scratch swelling. Nason ®<br />

SelectPrime <strong>421</strong>-20 is designed for those shops seeking a productive 2K primer with steady<br />

speed to sand that provides increased production capability during the repair process. <strong>421</strong>-20 is<br />

designed to maximize DOI (Distinctness of Image) when used under any Nason ® topcoat color.<br />

MIXING:<br />

4-1<br />

Mix:<br />

4 parts Nason ® SelectPrime <strong>421</strong>-20<br />

1 part Nason ® SelectPrime 483-53 or 483-83<br />

(Slow) Activator<br />

Example:<br />

To 1 gallon <strong>421</strong>-20 Primer-Surfacer add 1<br />

quart 483-53 Activator.<br />

TINTABILITY:<br />

Not recommended.<br />

POT LIFE:<br />

1 Hour at 70°F / 50% Relative Humidity<br />

SUBSTRATES:<br />

Properly treated bare steel, galvanized steel and<br />

aluminum; properly prepared painted surfaces.<br />

Treat bare metal areas with Nason ® 491-17 Etch<br />

Primer, or 491-16 Ful-Poxy Epoxy primer.<br />

SUBSTRATE PREPARATION:<br />

� Clean surface thoroughly with mild detergent<br />

and water.<br />

� For substrates other than plastic or fiberglass,<br />

wipe surface with Nason 441-05 Wax and<br />

Grease remover, 481-75 Aerosol Cleaner,<br />

or locally permitted cleaner.<br />

� Sand and featheredge according to the<br />

following minimum grit recommendations:<br />

Steel: P180 grit<br />

Aluminum: P320 grit, then pretreat<br />

Galvanized: P320 grit, then pretreat<br />

E-coat: P320 grit<br />

Cured paint: P320 grit<br />

OEM featheredge: P180 grit followed by P240<br />

grit<br />

Body filler: P180 grit<br />

2K putty: P180-P240 grit<br />

SMC/fiberglass: P180-P240 grit<br />

� Notes: Aluminum, galvanized, and steel must<br />

be pretreated with Nason 491-17 Etch<br />

Primer or 491-16 Ful-Poxy Epoxy Primer<br />

or other Nason ® Etch Primer or Epoxy Primer.<br />

Tips for Success:<br />

� When using coarse grit paper, step your way<br />

up through P80/P180/P240 grit prior to<br />

priming to remove coarse scratches and avoid<br />

sand scratch swelling in OEM finishes.<br />

� Finish sensitive substrates in P320 grit.<br />

� Sand beyond the area to be primed with P320<br />

grit or finer to ensure good adhesion at the<br />

thin edge of the primer.<br />

TOPCOATS:<br />

All Nason ® Topcoats<br />

SPRAY VISCOSITY:<br />

30”-35” #2 Zahn<br />

SPRAY PRESSURE:<br />

Conventional: 30-40 PSI<br />

HVLP: 8-10 PSI @ gun cap.<br />

Rev. 08/09 Copyright © 2009. E.I du Pont de Nemours and Company. All Rights Reserved.<br />

A Member of DuPont Performance Coatings ® and TM are registered trademarks/trademarks of E.I du Pont de Nemours and Company.

TYPICAL GUN SET-UPS:<br />

Conventional<br />

Siphon Feed: 1.8 mm – 2.0 mm<br />

Gravity Feed: 1.8 mm – 2.0 mm<br />

HVLP<br />

Siphon Feed: 1.8 mm – 2.0 mm<br />

Gravity Feed: 1.8 mm – 2.0 mm<br />

APPLICATION:<br />

Apply 3 medium wet coats. Allow 5-10 min. flash<br />

between coats.<br />

Tips for Success: Do not ignore flash times<br />

between coats; this prevents solvent entrapment<br />

that can cause pinholes, popping and shrinkage if<br />

flash is abused.<br />

DRYING TIME: TO SAND<br />

2.5 hours at 70°F when activated with 483-83 TM<br />

1 hour at 70°F when activated with 483-53 TM<br />

Lower temperatures may require longer flash<br />

times.<br />

SANDING:<br />

Sand wet or dry with #400 or finer paper. Clean<br />

sanding debris with Nason ® 441-05 Silicone and<br />

Wax Remover or locally permitted cleaner.<br />

SEALERS:<br />

No sealer is required but may be sealed with<br />

Nason ® SelectSeal 422-50 or any Nason ®<br />

Sealer.<br />

CLEANING OF PAINT EQUIPMENT:<br />

Use Nason ® 481-16 TM , Nason ® 481-21 TM Low<br />

VOC Gun & Equipment Cleaning Solvent, or<br />

any other DuPont equipment cleaner as<br />

permitted by local regulations.<br />

IMPORTANT NOTES:<br />

� Sanding is required for adhesion of topcoat to<br />

primer and optimal appearance.<br />

� <strong>421</strong>-20 can be used under any Nason ®<br />

topcoat system.<br />

<strong>Technical</strong> <strong>Manual</strong><br />

PHYSICAL PROPERTIES:<br />

VOC LE: 4.8 lbs/gal maximum, ready to spray<br />

Theoretical Coverage: 585 Sq. Ft. @ 1 mil<br />

Weight Solids: 56.2%<br />

Volume Solids: 36.5%<br />

Recommended Dry Film Thickness: 4-5 mils in 3<br />

coats<br />

Flash Point: See MSDS<br />

VOC REGULATED AREAS:<br />

These directions refer to the use of products which<br />

may be restricted or require special mixing<br />

instructions in VOC regulated areas. Follow mixing<br />

and usage recommendations in the VOC Compliant<br />

Products Chart for your area.<br />

SAFETY AND HANDLING:<br />

For industrial use only by professional, trained<br />

painters. Not for sale to or use by the general public.<br />

Before using, read and follow all label and MSDS<br />

precautions. If mixed with other components, mixture<br />

will have hazards of all components.<br />

Ready to use paint materials containing isocyanates<br />

can cause irritation of the respiratory organs and<br />

hypersensitive reactions. Asthma sufferers, those with<br />

allergies and anyone with a history of respiratory<br />

complaints must not be asked to work with products<br />

containing isocyanates.<br />

Do not sand, flame cut, braze or weld dry coating<br />

without a NIOSH approved air purifying respirator with<br />

particulate filters or appropriate ventilation, and<br />

gloves.<br />

Please visit: www.nason.dupont.com to view or print<br />

an additional copy of this technical “Product Data<br />

Sheet.”<br />

Rev. 08/09 Copyright © 2009. E.I du Pont de Nemours and Company. All Rights Reserved.<br />

A Member of DuPont Performance Coatings ® and TM are registered trademarks/trademarks of E.I du Pont de Nemours and Company.