CL-B0026(AP) Pearlized Shower Gel - Soap/Surfactant ... - Lubrizol

CL-B0026(AP) Pearlized Shower Gel - Soap/Surfactant ... - Lubrizol

CL-B0026(AP) Pearlized Shower Gel - Soap/Surfactant ... - Lubrizol

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

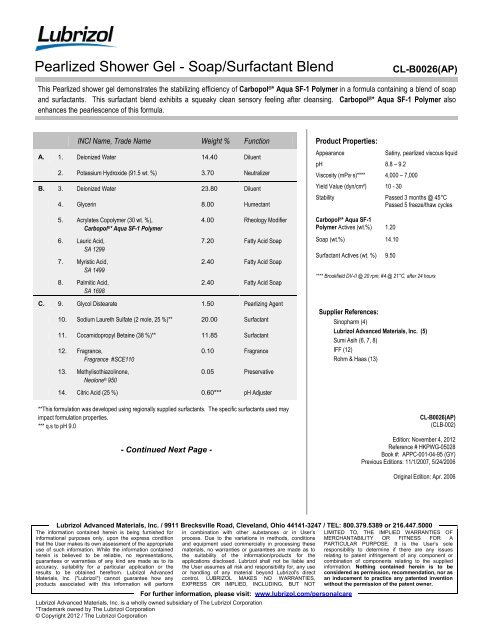

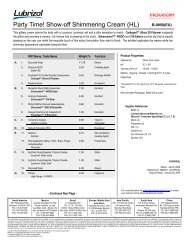

<strong>Pearlized</strong> <strong>Shower</strong> <strong>Gel</strong> - <strong>Soap</strong>/<strong>Surfactant</strong> Blend<br />

This <strong>Pearlized</strong> shower gel demonstrates the stabilizing efficiency of Carbopol ® * Aqua SF-1 Polymer in a formula containing a blend of soap<br />

and surfactants. This surfactant blend exhibits a squeaky clean sensory feeling after cleansing. Carbopol ® * Aqua SF-1 Polymer also<br />

enhances the pearlescence of this formula.<br />

INCI Name, Trade Name Weight % Function<br />

A. 1. Deionized Water 14.40 Diluent<br />

2. Potassium Hydroxide (91.5 wt. %) 3.70 Neutralizer<br />

:<br />

B. 3. Deionized Water 23.80 Diluent<br />

4. Glycerin 8.00 Humectant<br />

5. Acrylates Copolymer (30 wt. %),<br />

Carbopol ® * Aqua SF-1 Polymer<br />

6. Lauric Acid,<br />

SA 1299<br />

7. Myristic Acid,<br />

SA 1499<br />

8. Palmitic Acid,<br />

SA 1698<br />

4.00 Rheology Modifier<br />

7.20 Fatty Acid <strong>Soap</strong><br />

2.40 Fatty Acid <strong>Soap</strong><br />

2.40 Fatty Acid <strong>Soap</strong><br />

C. 9. Glycol Distearate 1.50 Pearlizing Agent<br />

10. Sodium Laureth Sulfate (2 mole, 25 %)** 20.00 <strong>Surfactant</strong><br />

11. Cocamidopropyl Betaine (38 %)** 11.85 <strong>Surfactant</strong><br />

12. Fragrance,<br />

Fragrance #SCE110<br />

13. Methylisothiazolinone,<br />

Neolone ® 950<br />

0.10 Fragrance<br />

0.05 Preservative<br />

14. Citric Acid (25 %) 0.60*** pH Adjuster<br />

**This formulation was developed using regionally supplied surfactants. The specific surfactants used may<br />

impact formulation properties.<br />

*** q.s to pH 9.0<br />

- Continued Next Page -<br />

Product Properties:<br />

Appearance Satiny, pearlized viscous liquid<br />

pH 8.8 – 9.2<br />

Viscosity (mPa·s)**** 4,000 – 7,000<br />

Yield Value (dyn/cm²) 10 - 30<br />

Stability Passed 3 months @ 45°C<br />

Passed 5 freeze/thaw cycles<br />

Carbopol ® * Aqua SF-1<br />

Polymer Actives (wt.%) 1.20<br />

<strong>Soap</strong> (wt.%) 14.10<br />

<strong>Surfactant</strong> Actives (wt. %) 9.50<br />

<strong>CL</strong>-<strong>B0026</strong>(<strong>AP</strong>)<br />

**** Brookfield DV-II @ 20 rpm, #4 @ 21°C, after 24 hours<br />

Supplier References:<br />

Sinopharm (4)<br />

<strong>Lubrizol</strong> Advanced Materials, Inc. (5)<br />

Sumi Asih (6, 7, 8)<br />

IFF (12)<br />

Rohm & Haas (13)<br />

<strong>CL</strong>-<strong>B0026</strong>(<strong>AP</strong>)<br />

(<strong>CL</strong>B-002)<br />

Edition: November 4, 2012<br />

Reference # HKPWG-05028<br />

Book #: <strong>AP</strong>PC-001-04-95 (GY)<br />

Previous Editions: 11/1/2007, 5/24/2006<br />

Original Edition: Apr. 2006<br />

<strong>Lubrizol</strong> Advanced Materials, Inc. / 9911 Brecksville Road, Cleveland, Ohio 44141-3247 / TEL: 800.379.5389 or 216.447.5000<br />

The information contained herein is being furnished for<br />

informational purposes only, upon the express condition<br />

that the User makes its own assessment of the appropriate<br />

use of such information. While the information contained<br />

herein is believed to be reliable, no representations,<br />

guarantees or warranties of any kind are made as to its<br />

accuracy, suitability for a particular application or the<br />

results to be obtained herefrom. <strong>Lubrizol</strong> Advanced<br />

Materials, Inc. ("<strong>Lubrizol</strong>") cannot guarantee how any<br />

products associated with this information will perform<br />

in combination with other substances or in User’s<br />

process. Due to the variations in methods, conditions<br />

and equipment used commercially in processing these<br />

materials, no warranties or guarantees are made as to<br />

the suitability of the information/products for the<br />

applications disclosed. <strong>Lubrizol</strong> shall not be liable and<br />

the User assumes all risk and responsibility for, any use<br />

or handling of any material beyond <strong>Lubrizol</strong>'s direct<br />

control. LUBRIZOL MAKES NO WARRANTIES,<br />

EXPRESS OR IMPLIED, IN<strong>CL</strong>UDING, BUT NOT<br />

For further information, please visit: www.lubrizol.com/personalcare<br />

<strong>Lubrizol</strong> Advanced Materials, Inc. is a wholly owned subsidiary of The <strong>Lubrizol</strong> Corporation<br />

*Trademark owned by The <strong>Lubrizol</strong> Corporation<br />

© Copyright 2012 / The <strong>Lubrizol</strong> Corporation<br />

LIMITED TO, THE IMPLIED WARRANTIES OF<br />

MERCHANTABILITY OR FITNESS FOR A<br />

PARTICULAR PURPOSE. It is the User’s sole<br />

responsibility to determine if there are any issues<br />

relating to patent infringement of any component or<br />

combination of components relating to the supplied<br />

information. Nothing contained herein is to be<br />

considered as permission, recommendation, nor as<br />

an inducement to practice any patented invention<br />

without the permission of the patent owner.

<strong>Pearlized</strong> <strong>Shower</strong> <strong>Gel</strong> - <strong>Soap</strong>/<strong>Surfactant</strong> Blend <strong>CL</strong>-<strong>B0026</strong>(<strong>AP</strong>)<br />

Procedure:<br />

1. PART A: Dissolve potassium hydroxide in water and heat to 80°C.<br />

2. PART B: Add glycerin and Carbopol ® * Aqua SF-1 Polymer to water.<br />

Mix well.<br />

3. Add fatty acids to PART B and heat to 80°C. Mix until all fatty acids<br />

have melted. Keep under agitation while maintaining the temperature at<br />

80°C.<br />

4. Add PART A to PART B maintaining the temperature at 80°C. Mix well<br />

for 30-60 minutes.<br />

5. Begin cooling the system. Add glycol distearate at 60-70°C with good<br />

agitation until dissolved.<br />

6. Add surfactants (Ingredients 10 and 11) in order shown. Mix until<br />

uniform.<br />

7. Add remaining ingredients at 40°C. Mix until uniform.<br />

8. Adjust pH with citric acid solution to about 9.0.