Formulating Hydroalcoholic Gels with Carbopol Technical ... - Lubrizol

Formulating Hydroalcoholic Gels with Carbopol Technical ... - Lubrizol

Formulating Hydroalcoholic Gels with Carbopol Technical ... - Lubrizol

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Formulation and Manufacturing Guidelines<br />

• Typical hand sanitizing gels contain less that 40<br />

wt% water. Due to this formulation constraint, a<br />

common concern is how to effectively incorporate<br />

the <strong>Carbopol</strong> polymer. The general methods are<br />

outlined as follows, dependent on your choice of<br />

polymer:<br />

Direct Method: The direct method is the traditional<br />

method for dispersing <strong>Carbopol</strong> polymers.<br />

<strong>Carbopol</strong> Ultrez Polymers: This method is made<br />

easy <strong>with</strong> <strong>Carbopol</strong> Ultrez polymers since you simply<br />

sprinkle the polymer on the surface of the water.<br />

Allow the polymer to self wet and then begin<br />

agitation. The general procedure is described as<br />

follows:<br />

1. Disperse the polymer into the water. Mix until<br />

smooth to insure a lump free dispersion is<br />

obtained.<br />

2. Slowly add the alcohol <strong>with</strong> agitation and mix until<br />

homogeneous.<br />

3. Add emollients if desired. Keep in mind that the<br />

order of addition may be critical to maintain<br />

product clarity. See “Adding Emollients” for<br />

further information.<br />

4. Add the appropriate neutralizing agent <strong>with</strong> gentle<br />

sweeping agitation and mix until smooth.<br />

NOTE: If production equipment constraints require<br />

the water and alcohol to be combined before the<br />

dispersion of polymer, the <strong>Carbopol</strong> Ultrez polymers<br />

must be dispersed like a traditional polymer. The<br />

<strong>Carbopol</strong> Ultrez grade polymers will not self wet in a<br />

solution of water and alcohol.<br />

<strong>Carbopol</strong> Traditional Grade Polymers: These<br />

polymers can be dispersed in either the water or<br />

alcohol/water mixture. The polymer will swell more<br />

slowly when added to the alcohol/water mixture, so<br />

care must be taken to avoid the clumping and<br />

skinning of the polymer during the dispersion<br />

process.<br />

1. Carefully disperse the polymer in the water or<br />

water/alcohol mixture <strong>with</strong> good agitation. High<br />

mixing speeds are generally preferred as it<br />

prevents agglomeration of the polymer on the<br />

surface of the water. Mix until the polymer is<br />

hydrated and the dispersion is smooth and free of<br />

lumps.<br />

TDS-255<br />

<strong>Formulating</strong> <strong>Hydroalcoholic</strong> <strong>Gels</strong> <strong>with</strong> <strong>Carbopol</strong> ® Polymers<br />

Page 5 of 6<br />

2. Add the alcohol <strong>with</strong> slow mixing to de-aerate the<br />

formulation if it was not included in Step 1.<br />

3. Add emollients if desired. Keep in mind that the<br />

order of addition may be critical to maintain<br />

product clarity. See “Adding Emollients” for<br />

further information.<br />

4. Add the appropriate neutralizing agent <strong>with</strong> gentle<br />

sweeping agitation and mix until smooth.<br />

• Water Source: Use deionized water. <strong>Carbopol</strong><br />

polymers are sensitive to hard water ions,<br />

therefore, the clarity and viscosity may be<br />

negatively affected if regular tap water is used. If<br />

deionized water is unavailable, add a chelating<br />

agent such as tetrasodium EDTA at a level of<br />

about 0.05-0.10% (wt/wt%).<br />

• Adding Emollients: Several commercially<br />

available emollients can be added to the hand<br />

sanitizing gel to compensate for removal of oils<br />

on the hands by the alcohol. The following watersoluble<br />

emollients can be added directly to the<br />

water and polymer dispersion or just before<br />

neutralization. The use of these emollients from<br />

0.3-0.5 wt% addition will not impact the final<br />

product clarity.<br />

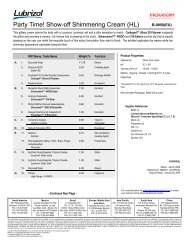

Trade Name INCI Name<br />

Glucam E-20 Humectant Methyl Gluceth-20<br />

Glucam E-10 Humectant Methyl Gluceth-10<br />

SilSense Copolyol-1 Silicone PEG-33 and PEG-8<br />

Dimethicone and PEG-14<br />

SilSense SW-12 Silicone Ester Dimethicone PEG-7 Cocoate<br />

Hydramol PGPL Emollient PEG/PPG-8/3 Laurate<br />

Hydramol PGDS Emollient PEG-90 Diisostearate<br />

The Hydramol emollients can be added at use<br />

levels from 0.5-3.0 wt% and still maintain good clarity<br />

in the system.<br />

The use of other emollients may impact the final<br />

product clarity depending on the solubility profile of<br />

that particular emollient. Other emollients, such as<br />

isopropyl myristate, may need to be added to the<br />

alcohol and the water/polymer dispersion added to<br />

the alcohol/emollient phase to maintain final product<br />

clarity.