Integrierte Vermeidung und Verminderung der Umweltverschmutzung

Integrierte Vermeidung und Verminderung der Umweltverschmutzung Integrierte Vermeidung und Verminderung der Umweltverschmutzung

Chapter 3 3.3.1 Meat and poultry 3.3.1.1 General information 3.3.1.1.1 Water The main environmental impact of meat and poultry manufacturing is the production of waste water. Significant quantities of water are used for washing and thawing meat. The reported water consumption is about 3 – 5 m 3 /t. The water used for thawing can be recirculated in a closed-circuit and used again [182, Germany, 2003]. Some other major water consuming steps are, e.g. pasteurising, sterilising, cooling, cleaning and disinfection. Stringent hygiene measures are applied to the cutting and chilling of carcases which lead to relatively large quantities of waste water arising from equipment and installation cleaning. 3.3.1.1.2 Air emissions Air pollution is produced mainly due to the operation of boilers and smokers. Odour may be a nuisance. Refrigerants may leak causing air pollution. 3.3.1.1.3 Solid output Cutting and deboning meat and poultry produces bones, fat and skin. The use of animal byproducts is regulated by Regulation 1774/2002/EC [188, EC, 2002]. Bones and fat may be used for, e.g. producing glue and detergents, or for producing gelatine which can be used, e.g. in some cases in the food or pharmaceutical industries. Some animal by-products must be disposed of as waste. Solid output may also be produced in packing operations such as waste packaging. Table 3.10 shows the proportion of carcases considered to be by-products. By-products in cutting/deboning (% of carcase weight) Beef Pig Poultry Bones Fat 12 5 – 9.5 3 – 6 1 – 2 6 Skin 1 – 2 Table 3.10: By-products in cutting and deboning meat [134, AWARENET, 2002] 3.3.1.1.4 Energy A considerable amount of thermal energy is used in processes involving heat treatments such as boiling, cooking, pasteurising, sterilising drying and smoking. Other large energy consuming operations are chilling, freezing, thawing, and cleaning and disinfection. 3.3.1.2 Meat and poultry production 3.3.1.2.1 General information This category covers a wide range of products and processing techniques, which are not practicable to consider individually. All lines, equipment and process areas that are not in designated dry areas require wet cleaning, which generates waste water contaminated with the product, raw materials and cleaning chemicals. If scraps are washed down the drain, this will increase the COD, fat and SS content of the waste water. Cooking methods that involve direct contact between water or steam and product, produce waste water, as do cooling, chilling, freezing and filling operations. Ingredients added to the meat may enter the waste water stream as a result of equipment washouts and spillage. Those used in large quantities, e.g. batter, breadcrumbs and cooking oil, can make a significant contribution to the BOD, TSS and FOG levels of the waste water. 150 January 2006 RHC/EIPPCB/FDM_BREF_FINAL

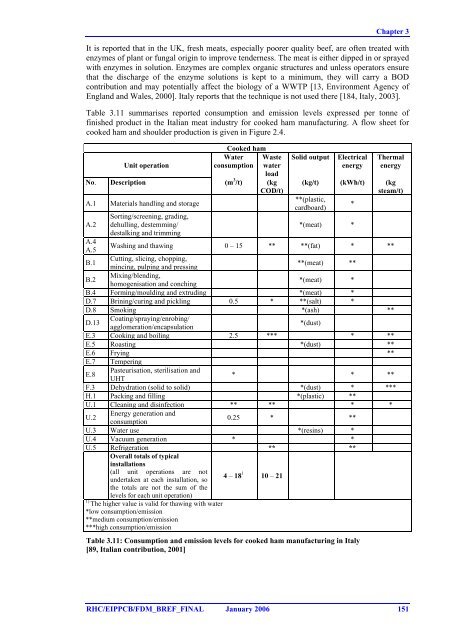

Chapter 3 It is reported that in the UK, fresh meats, especially poorer quality beef, are often treated with enzymes of plant or fungal origin to improve tenderness. The meat is either dipped in or sprayed with enzymes in solution. Enzymes are complex organic structures and unless operators ensure that the discharge of the enzyme solutions is kept to a minimum, they will carry a BOD contribution and may potentially affect the biology of a WWTP [13, Environment Agency of England and Wales, 2000]. Italy reports that the technique is not used there [184, Italy, 2003]. Table 3.11 summarises reported consumption and emission levels expressed per tonne of finished product in the Italian meat industry for cooked ham manufacturing. A flow sheet for cooked ham and shoulder production is given in Figure 2.4. Unit operation Cooked ham Water consumption Waste water RHC/EIPPCB/FDM_BREF_FINAL January 2006 151 load No. Description (m 3 /t) (kg COD/t) A.1 Materials handling and storage A.2 A.4 A.5 Sorting/screening, grading, dehulling, destemming/ destalking and trimming Solid output Electrical energy Thermal energy (kg/t) (kWh/t) (kg steam/t) **(plastic, cardboard) * *(meat) * Washing and thawing 0 – 15 ** **(fat) * ** B.1 Cutting, slicing, chopping, mincing, pulping and pressing **(meat) ** B.2 Mixing/blending, homogenisation and conching *(meat) * B.4 Forming/moulding and extruding *(meat) * D.7 Brining/curing and pickling 0.5 * **(salt) * D.8 Smoking *(ash) ** D.13 Coating/spraying/enrobing/ agglomeration/encapsulation *(dust) E.3 Cooking and boiling 2.5 *** * ** E.5 Roasting *(dust) ** E.6 Frying ** E.7 Tempering E.8 Pasteurisation, sterilisation and UHT * * ** F.3 Dehydration (solid to solid) *(dust) * *** H.1 Packing and filling *(plastic) ** U.1 Cleaning and disinfection ** ** * * U.2 Energy generation and consumption 0.25 * ** U.3 Water use *(resins) * U.4 Vacuum generation * * U.5 Refrigeration Overall totals of typical installations ** ** (all unit operations are not undertaken at each installation, so the totals are not the sum of the levels for each unit operation) 4 – 18 1 10 – 21 1) The higher value is valid for thawing with water *low consumption/emission **medium consumption/emission ***high consumption/emission Table 3.11: Consumption and emission levels for cooked ham manufacturing in Italy [89, Italian contribution, 2001]

- Seite 159 und 160: Chapter 2 In the UK, the majority o

- Seite 161 und 162: 2.2.11.5 Boiled sweets Chapter 2 Bo

- Seite 163 und 164: 2.2.13.2 Instant coffee Chapter 2 I

- Seite 165 und 166: Chapter 2 The indirect method is ca

- Seite 167 und 168: 2.2.16.1 Mashing Chapter 2 Grains a

- Seite 169 und 170: 2.2.18 Wine This section includes r

- Seite 171: Chapter 2 In citric acid fermentati

- Seite 174 und 175: Chapter 3 The consumption and emiss

- Seite 176 und 177: Chapter 3 Surface water 23% Other w

- Seite 178 und 179: Chapter 3 3.1.2 Air emissions Air e

- Seite 180 und 181: Chapter 3 3.1.3.4 Product defects/r

- Seite 182 und 183: Chapter 3 C.9 Bleaching N N W1,W3 C

- Seite 184 und 185: Chapter 3 3.2.1.3 Solid output Some

- Seite 186 und 187: Chapter 3 3.2.4.3 Energy The electr

- Seite 188 und 189: Chapter 3 3.2.9 Extraction (C.1) 3.

- Seite 190 und 191: Chapter 3 3.2.13.3 Solid output Fil

- Seite 192 und 193: Chapter 3 3.2.18.5 Noise Noise issu

- Seite 194 und 195: Chapter 3 3.2.24 Fermentation (D.4)

- Seite 196 und 197: Chapter 3 3.2.29.4 Energy Energy is

- Seite 198 und 199: Chapter 3 3.2.36.2 Air emissions St

- Seite 200 und 201: Chapter 3 3.2.40.3 Solid output Oil

- Seite 202 und 203: Chapter 3 3.2.45 Dehydration (solid

- Seite 204 und 205: Chapter 3 3.2.48 Freeze-drying/lyop

- Seite 206 und 207: Chapter 3 3.2.52.3 Solid output Ash

- Seite 208 und 209: Chapter 3 Sector Water consumption

- Seite 212 und 213: Chapter 3 3.3.1.2.2 Salami and saus

- Seite 214 und 215: Chapter 3 Unit operation Cured ham

- Seite 216 und 217: Chapter 3 3.3.2.1 Water consumption

- Seite 218 und 219: Chapter 3 By-products from the fill

- Seite 220 und 221: Chapter 3 LIQUID WASTE IN VOLUME/WE

- Seite 222 und 223: Chapter 3 Product category Water co

- Seite 224 und 225: Chapter 3 Unit operation Tomato jui

- Seite 226 und 227: Chapter 3 Product Waste water volum

- Seite 228 und 229: Chapter 3 Flume water Raw produce s

- Seite 230 und 231: Chapter 3 LIQUID WASTE IN VOLUME/WE

- Seite 232 und 233: Chapter 3 • production of animal

- Seite 234 und 235: Chapter 3 Both water and steam blan

- Seite 236 und 237: Chapter 3 Energy carrier Approximat

- Seite 238 und 239: Chapter 3 3.3.3.5.4 Juices Energy i

- Seite 240 und 241: Chapter 3 Source Volume m 3 /t 1 BO

- Seite 242 und 243: Chapter 3 Deodoriser distillate, co

- Seite 244 und 245: Chapter 3 In oilseed processing, 0.

- Seite 246 und 247: Chapter 3 Product Water consumption

- Seite 248 und 249: Chapter 3 Component Range SS 24 - 5

- Seite 250 und 251: Chapter 3 For cheese manufacturing,

- Seite 252 und 253: Chapter 3 LIQUID WASTE IN VOLUME/WE

- Seite 254 und 255: Chapter 3 Total energy consumption

- Seite 256 und 257: Chapter 3 Estimated energy consumpt

- Seite 258 und 259: Chapter 3 While the overall water u

Chapter 3<br />

It is reported that in the UK, fresh meats, especially poorer quality beef, are often treated with<br />

enzymes of plant or fungal origin to improve ten<strong>der</strong>ness. The meat is either dipped in or sprayed<br />

with enzymes in solution. Enzymes are complex organic structures and unless operators ensure<br />

that the discharge of the enzyme solutions is kept to a minimum, they will carry a BOD<br />

contribution and may potentially affect the biology of a WWTP [13, Environment Agency of<br />

England and Wales, 2000]. Italy reports that the technique is not used there [184, Italy, 2003].<br />

Table 3.11 summarises reported consumption and emission levels expressed per tonne of<br />

finished product in the Italian meat industry for cooked ham manufacturing. A flow sheet for<br />

cooked ham and shoul<strong>der</strong> production is given in Figure 2.4.<br />

Unit operation<br />

Cooked ham<br />

Water<br />

consumption<br />

Waste<br />

water<br />

RHC/EIPPCB/FDM_BREF_FINAL January 2006 151<br />

load<br />

No. Description (m 3 /t) (kg<br />

COD/t)<br />

A.1 Materials handling and storage<br />

A.2<br />

A.4<br />

A.5<br />

Sorting/screening, grading,<br />

dehulling, destemming/<br />

destalking and trimming<br />

Solid output Electrical<br />

energy<br />

Thermal<br />

energy<br />

(kg/t) (kWh/t) (kg<br />

steam/t)<br />

**(plastic,<br />

cardboard)<br />

*<br />

*(meat) *<br />

Washing and thawing 0 – 15 ** **(fat) * **<br />

B.1<br />

Cutting, slicing, chopping,<br />

mincing, pulping and pressing<br />

**(meat) **<br />

B.2<br />

Mixing/blending,<br />

homogenisation and conching<br />

*(meat) *<br />

B.4 Forming/moulding and extruding *(meat) *<br />

D.7 Brining/curing and pickling 0.5 * **(salt) *<br />

D.8 Smoking *(ash) **<br />

D.13 Coating/spraying/enrobing/<br />

agglomeration/encapsulation<br />

*(dust)<br />

E.3 Cooking and boiling 2.5 *** * **<br />

E.5 Roasting *(dust) **<br />

E.6 Frying **<br />

E.7 Tempering<br />

E.8<br />

Pasteurisation, sterilisation and<br />

UHT<br />

* * **<br />

F.3 Dehydration (solid to solid) *(dust) * ***<br />

H.1 Packing and filling *(plastic) **<br />

U.1 Cleaning and disinfection ** ** * *<br />

U.2<br />

Energy generation and<br />

consumption<br />

0.25 * **<br />

U.3 Water use *(resins) *<br />

U.4 Vacuum generation * *<br />

U.5 Refrigeration<br />

Overall totals of typical<br />

installations<br />

** **<br />

(all unit operations are not<br />

<strong>und</strong>ertaken at each installation, so<br />

the totals are not the sum of the<br />

levels for each unit operation)<br />

4 – 18 1 10 – 21<br />

1)<br />

The higher value is valid for thawing with water<br />

*low consumption/emission<br />

**medium consumption/emission<br />

***high consumption/emission<br />

Table 3.11: Consumption and emission levels for cooked ham manufacturing in Italy<br />

[89, Italian contribution, 2001]