298 94 307/02 Untersuchungen zum Stand der Umsetzung des ...

298 94 307/02 Untersuchungen zum Stand der Umsetzung des ... 298 94 307/02 Untersuchungen zum Stand der Umsetzung des ...

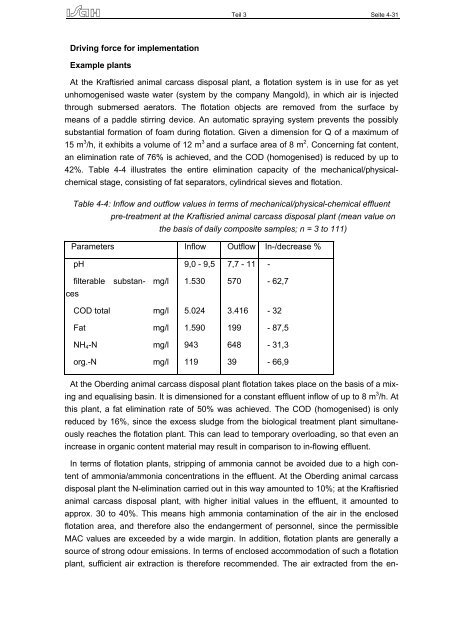

Driving force for implementation Example plants Teil 3 Seite 4-31 At the Kraftisried animal carcass disposal plant, a flotation system is in use for as yet unhomogenised waste water (system by the company Mangold), in which air is injected through submersed aerators. The flotation objects are removed from the surface by means of a paddle stirring device. An automatic spraying system prevents the possibly substantial formation of foam during flotation. Given a dimension for Q of a maximum of 15 m 3 /h, it exhibits a volume of 12 m 3 and a surface area of 8 m 2 . Concerning fat content, an elimination rate of 76% is achieved, and the COD (homogenised) is reduced by up to 42%. Table 4-4 illustrates the entire elimination capacity of the mechanical/physical- chemical stage, consisting of fat separators, cylindrical sieves and flotation. Table 4-4: Inflow and outflow values in terms of mechanical/physical-chemical effluent pre-treatment at the Kraftisried animal carcass disposal plant (mean value on the basis of daily composite samples; n = 3 to 111) Parameters Inflow Outflow In-/decrease % ces pH 9,0 - 9,5 7,7 - 11 - filterable substan- mg/l 1.530 570 - 62,7 COD total mg/l 5.024 3.416 - 32 Fat mg/l 1.590 199 - 87,5 NH4-N mg/l 943 648 - 31,3 org.-N mg/l 119 39 - 66,9 At the Oberding animal carcass disposal plant flotation takes place on the basis of a mix- ing and equalising basin. It is dimensioned for a constant effluent inflow of up to 8 m 3 /h. At this plant, a fat elimination rate of 50% was achieved. The COD (homogenised) is only reduced by 16%, since the excess sludge from the biological treatment plant simultane- ously reaches the flotation plant. This can lead to temporary overloading, so that even an increase in organic content material may result in comparison to in-flowing effluent. In terms of flotation plants, stripping of ammonia cannot be avoided due to a high con- tent of ammonia/ammonia concentrations in the effluent. At the Oberding animal carcass disposal plant the N-elimination carried out in this way amounted to 10%; at the Kraftisried animal carcass disposal plant, with higher initial values in the effluent, it amounted to approx. 30 to 40%. This means high ammonia contamination of the air in the enclosed flotation area, and therefore also the endangerment of personnel, since the permissible MAC values are exceeded by a wide margin. In addition, flotation plants are generally a source of strong odour emissions. In terms of enclosed accommodation of such a flotation plant, sufficient air extraction is therefore recommended. The air extracted from the en-

Teil 3 Seite 4-32 closed area can be utilised in compressors and in this way fed into the ventilators for the biological treatment plant. Oberding animal carcass treatment plant, Germany, Kraftesried animal carcass treat- ment plant, 87647 Unterthingau, Germany Corporate clarification plant of the East Bavarian Meat Flour Association,94447 Plattling Clarification plant of the Union for Animal Carcass Disposal (Zweckverband für Tierkör- perbeseitigung) Lenz, 01561 Lenz, Germany Rethmann TBA Genthin GmbH, 39307 Mützel, Germany Waste water pre-treatment for Bauerngut Fleisch- und Wurstwaren GmbH, Könnern, Germany, Anaerobic waste treatment of the NFZ pork slaughterhouse in Emstek, District of Cloppenburg, Germany Pre-treatment slaughterhouse, North-Rhine Westphalia, waste water pre-treatment plant slaughterhouse, Saxony Anhalt, Germany Reference literature ATV-Handbuch Industrieabwasser (Dienstleistungs und Veredelungsindustrie) ATV-Handbuch Industrieabwasser (Lebensmittelindustrie) 4.5.2.6 Chemical and physical techniques (AT3535005) Description Achieved environmental benefits Cross media effects Operational data Applicability Economics Driving force for implementation Example plants Oberding animal carcass disposal plant, Germany Reference literature 4.5.3 Biological treatment Normally, the existing production wastewater from slaughterhouses and meat production plants are discharged into municipal sewage systems and conveyed to central mechani- cal-biological wastewater treatment plants. As the organic substances contained in this wastewater are easily bio-degradable, it is not difficult to subject them to a full treatment together with domestic wastewater.

- Seite 207 und 208: Teil 3 Seite 1-14 The amount of ste

- Seite 209 und 210: Teil 3 Seite 2-1 2 PROCESSES AND TE

- Seite 211 und 212: 2.1.1.1 Lairage Teil 3 Seite 2-3 As

- Seite 213 und 214: Teil 3 Seite 2-5 the rumen is spin-

- Seite 215 und 216: 2.1.2.1 Delivery of birds 2.1.2.2 S

- Seite 217 und 218: Teil 3 Seite 2-9 Figure 2-3: Presen

- Seite 219 und 220: - Rinsing of the carcasses and carc

- Seite 221 und 222: Teil 3 Seite 3-4 the currently usua

- Seite 223 und 224: Zerlegung 2% Schlachtung 30% Schlac

- Seite 225 und 226: 3.1.3.4 Plucking 3.1.3.5 Eviscerati

- Seite 227 und 228: Liquid phase from the dewatering (y

- Seite 229 und 230: Teil 3 Seite 4-2 - Re- use of salt

- Seite 231 und 232: [to be completed] Main achieved env

- Seite 233 und 234: Teil 3 Seite 4-6 - Efficient use an

- Seite 235 und 236: Teil 3 Seite 4-8 heat exchangers, p

- Seite 237 und 238: Teil 3 Seite 4-10 The situation wit

- Seite 239 und 240: Teil 3 Seite 4-12 rect evaporation

- Seite 241 und 242: Teil 3 Seite 4-14 Additional heat e

- Seite 243 und 244: Weight loss after 24 hours Temperat

- Seite 245 und 246: 4.2.5 Evisceration Reference to act

- Seite 247 und 248: Achieved environmental benefits Cro

- Seite 249 und 250: 4.5.1 Mechanical treatment 4.5.1.1

- Seite 251 und 252: Teil 3 Seite 4-24 Both in terms of

- Seite 253 und 254: Teil 3 Seite 4-26 4.5.2.1 Ammoniaca

- Seite 255 und 256: Teil 3 Seite 4-28 Brögbern animal

- Seite 257: Teil 3 Seite 4-30 The decision depe

- Seite 261 und 262: Teil 3 Seite 4-34 coincides with th

- Seite 263 und 264: Teil 3 Seite 4-36 At a slaughterhou

- Seite 265 und 266: Age of sludge (tTS) Is this of spec

- Seite 267 und 268: Example plants Teil 3 Seite 4-40 Co

- Seite 269 und 270: BSB5 - load Bd (BSB ) NH4 -N - load

- Seite 271 und 272: Fe Fl Fe Fl P D MB Teil 3 Seite 4-4

- Seite 273 und 274: Teil 3 Seite 4-46 Parameters Unit M

- Seite 275 und 276: Teil 3 Seite 4-48 To optimise the m

- Seite 277 und 278: Driving force for implementation Ex

- Seite 279 und 280: Teil 3 Seite 4-52 Table 4-15 Dimens

- Seite 281 und 282: Teil 3 Seite 4-54 liquid fertiliser

- Seite 283 und 284: - No cross media effects Teil 3 Sei

- Seite 285 und 286: Teil 3 Seite 4-58 3. Filtermaterial

- Seite 287 und 288: Decomposition level Measure- Teil 3

- Seite 289 und 290: Teil 3 Seite 6-2 FAT/ HEAT TRANSFER

- Seite 291 und 292: Teil 3 Seite 6-4 Clarification plan

- Seite 293 und 294: Teil 3 Seite 6-6 ENERGY FAT/ HEAT C

- Seite 295 und 296: Teil 3 Seite 6-8 ENERGY/ STEAM INPU

- Seite 297 und 298: Teil 3 Seite 6-10 water if necessar

- Seite 299 und 300: Teil 3 Seite 6-12 - In- vessel comp

- Seite 301 und 302: Teil 3 Seite 6-14 For 1000 kg of de

- Seite 303 und 304: Teil 3 Seite 6-16 Liming is usually

- Seite 305 und 306: Teil 3 Seite 6-18 ceous earth filte

- Seite 307 und 308: See description under 1 Limed bone

Driving force for implementation<br />

Example plants<br />

Teil 3 Seite 4-31<br />

At the Kraftisried animal carcass disposal plant, a flotation system is in use for as yet<br />

unhomogenised waste water (system by the company Mangold), in which air is injected<br />

through submersed aerators. The flotation objects are removed from the surface by<br />

means of a paddle stirring device. An automatic spraying system prevents the possibly<br />

substantial formation of foam during flotation. Given a dimension for Q of a maximum of<br />

15 m 3 /h, it exhibits a volume of 12 m 3 and a surface area of 8 m 2 . Concerning fat content,<br />

an elimination rate of 76% is achieved, and the COD (homogenised) is reduced by up to<br />

42%. Table 4-4 illustrates the entire elimination capacity of the mechanical/physical-<br />

chemical stage, consisting of fat separators, cylindrical sieves and flotation.<br />

Table 4-4: Inflow and outflow values in terms of mechanical/physical-chemical effluent<br />

pre-treatment at the Kraftisried animal carcass disposal plant (mean value on<br />

the basis of daily composite samples; n = 3 to 111)<br />

Parameters Inflow Outflow In-/decrease %<br />

ces<br />

pH 9,0 - 9,5 7,7 - 11 -<br />

filterable substan-<br />

mg/l 1.530 570 - 62,7<br />

COD total mg/l 5.<strong>02</strong>4 3.416 - 32<br />

Fat mg/l 1.590 199 - 87,5<br />

NH4-N mg/l <strong>94</strong>3 648 - 31,3<br />

org.-N mg/l 119 39 - 66,9<br />

At the Oberding animal carcass disposal plant flotation takes place on the basis of a mix-<br />

ing and equalising basin. It is dimensioned for a constant effluent inflow of up to 8 m 3 /h. At<br />

this plant, a fat elimination rate of 50% was achieved. The COD (homogenised) is only<br />

reduced by 16%, since the excess sludge from the biological treatment plant simultane-<br />

ously reaches the flotation plant. This can lead to temporary overloading, so that even an<br />

increase in organic content material may result in comparison to in-flowing effluent.<br />

In terms of flotation plants, stripping of ammonia cannot be avoided due to a high con-<br />

tent of ammonia/ammonia concentrations in the effluent. At the Oberding animal carcass<br />

disposal plant the N-elimination carried out in this way amounted to 10%; at the Kraftisried<br />

animal carcass disposal plant, with higher initial values in the effluent, it amounted to<br />

approx. 30 to 40%. This means high ammonia contamination of the air in the enclosed<br />

flotation area, and therefore also the endangerment of personnel, since the permissible<br />

MAC values are exceeded by a wide margin. In addition, flotation plants are generally a<br />

source of strong odour emissions. In terms of enclosed accommodation of such a flotation<br />

plant, sufficient air extraction is therefore recommended. The air extracted from the en-