PDF-Prospektblatt - Esska Maschinen Vertriebs GmbH

PDF-Prospektblatt - Esska Maschinen Vertriebs GmbH

PDF-Prospektblatt - Esska Maschinen Vertriebs GmbH

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

MatCut 700<br />

ESSKA<br />

<strong>Maschinen</strong><br />

ESSKA<br />

<strong>Vertriebs</strong><br />

<strong>GmbH</strong><br />

Web: http://www.esska.de<br />

Mail: info@esska.de<br />

Instructions<br />

5. Precision cutting<br />

- Tightly rolled materials are easier to cur accurately.<br />

- The knives must cur without pressure at their own speed.<br />

- The blade must be sharp. The precision cutting devise must be used.<br />

6. Changing of the knives<br />

- Dissconnect all power to the machine. Wear thick, protective gloves.<br />

the knives - Pull down the hoop in horizontal position over the tube.<br />

- Remove the cam-cover (E-1)<br />

- Loosen the cap screw (E-2) by hammering on the key and remove the screw.<br />

- Remove the pointed cap head screw (E-10) on the bottom side of the cams by<br />

turning the screw a few times.<br />

- Remove the closer cam (E-9) by pulling it away from the motor towards ist axle.<br />

(The cam includes parts E-4 through E-9 of the block)<br />

- Turn the cam by hand so that the knife pin (E-11) can be removed.<br />

- Also remove the pin (E-11) of the left knife.<br />

- Fold the knife protection device upwards.<br />

- All the front of the hoop, (the side where machine is operated from) remove the<br />

screw on the bottom at the right side of the hoop. This screw passes through and<br />

holds up the knife. When removing the screw, hold the knife tightly.<br />

- Remove the knives by holding them down slightly, pulling them towards you.<br />

- Follow the above procedure in reverse to install the new knives.<br />

7. Maintenance<br />

Your MATCUT 700 is virtually maintenance free. However, the knives need to be<br />

serviced as follows: It may be possible that the finish and binder of the glassfibre<br />

accumulated on the knives. Remove such waste by using a special solvent. Inspect<br />

the inside of the knives for debris and clean them. Grease the inside of the blades<br />

from time to time with a heat resistant grease (Molykote). Regular inspection and<br />

cleaning of the blades will extend their life.<br />

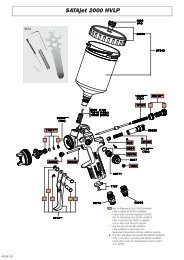

8. Spare Parts<br />

The following are recommended for spare parts for the MATCUT 700 is extremely low.<br />

They are as follows<br />

- Knife ME-80R, ME-80L. They may ve sharpenend.<br />

- Knife bolt E-11<br />

9. Material to be cut with MATCUT 700<br />

It is generally recomended that MATCUT 700 is used for the cutting of the following<br />

materials only: glassfibre, materials and core fleeces such as Coremat Firet, Upica<br />

Mat, Spherecore etc. Synthetic materials when cut are weld themselves easily toghether<br />

again. Moreover, the cutting action can be problematic. Any responsibility<br />

and/or liability is strictly refused in the event that other than those materials mentioned<br />

above are being cut with MATCUT 700.<br />

ESSKA <strong>Maschinen</strong> <strong>Vertriebs</strong> <strong>GmbH</strong> * Wöhlerstrasse 8 * D-22113 Hamburg * Tel. +49-(0)40-731 036-0 * Fax +49-(0)40-731 036 50<br />

KF Technik Handel <strong>GmbH</strong> * Am Fischereihafen 101 * D-18069 Rostock * Tel. +49-(0)381-800 58 24 * Fax +49-(0)381-800 58 26<br />

Sweden ESSKA Industriteknik * Karlstadsvägen 2 * S-67142 Arvika * Tel. +46-(0)570-711 622 * Fax +46-(0)570-711 622