Magster-280 4x4,-330 4x4 - Lincoln Electric - documentations

Magster-280 4x4,-330 4x4 - Lincoln Electric - documentations

Magster-280 4x4,-330 4x4 - Lincoln Electric - documentations

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

To mount the electrode wire spool, you should:<br />

Twist off the brake sleeve cap (1).<br />

Put on the spool with the wire (2) in such a way to<br />

unwind the spool clockwise.<br />

Make sure if the guide pin has reached the guide<br />

whole of the spool.<br />

Twist on the brake sleeve cap (1).<br />

Make certain if groves of drive rolls are compatible with<br />

thewirediameter.<br />

Insert the electrode wire into the wire feeder.<br />

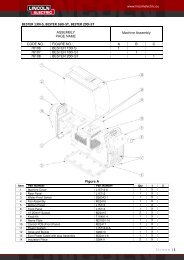

Drive Roll Replacement<br />

Adjustment of Braking Torque of the<br />

Sleeve<br />

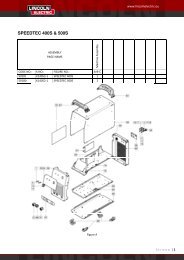

Fig.3<br />

To prevent electrode wire unwinding at the welding<br />

finishing, you should adjust braking torque of the sleeve:<br />

Twist off the brake sleeve cap (1).<br />

To increase the braking torque, you should turn M10 bolt<br />

(2) clockwise.<br />

To decrease the braking torque, you should turn M10<br />

bolt (2) counterclockwise.<br />

Twist on the brake sleeve cap after adjusting finish.<br />

Shielding Gas Connection<br />

To connect shielding gas, you should:<br />

Fig. 2<br />

To replace the drive roll you should:<br />

Release the roll pressure arms (5) of the wire drive.<br />

Twist off the roll fastening caps (4).<br />

Take off the drive rolls (3).<br />

Make sure if the key (2) remained in the gear furrow<br />

(1).<br />

Put on the new rolls (3) with diameter and groove<br />

shape adequate for used wire.<br />

Twist on the roll fastening caps (4).<br />

Cut the end of the wire, making sure if there isn’t any<br />

burr.<br />

Insert the wire into the wire feeder as far as EURO<br />

socket (turning the spool clockwise).<br />

Snap the roll pressure arms (5).<br />

Adjust optimum rolls pressure by means of the roll<br />

pressure arm thumbscrew.<br />

After placing the shielding gas cylinder on the platform,<br />

protect it against to overturn with the chain.<br />

Take off the hub cap of the safety valve of the shielding<br />

gas cylinder.<br />

Install the regulator on the gas cylinder.<br />

Connect the regulator to the <strong>Magster</strong> with gas hose<br />

using band clip.<br />

Welding with CO 2, it is recommended to use the gas<br />

heater. It can be powered from the socket placed on<br />

rear panel.<br />

Controls and Operational Features<br />

Inserting Electrode Wire into the Wire<br />

Feeder<br />

To insert the electrode wire into the wire feeder, you<br />

should:<br />

Match the welding torch with rated parameters<br />

compatible with the power source parameters and<br />

connect it to the EURO socket.<br />

Twist off the nozzle and the contact tip.<br />

Set the WFS control knob in half of the range.<br />

Press the Cold Inch button and hold it until the electrode<br />

wire goes out from the GUN.<br />

Twist on the nozzle and the contact tip again.<br />

ATTENTION<br />

Don’t look into the outlet of the torch during cold<br />

inching - going out wire can seriously injure your<br />

eye.<br />

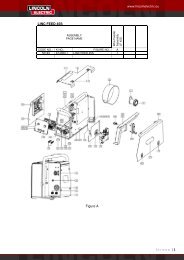

Fig. 4<br />

1. Power Switch: Turns the machine on/off. Switching<br />

on is indicated by lighting up of the switch button.<br />

2. WFS (Wire Feed Speed) Knob: 10-position scale<br />

enables stepless WFS control in a range of 1-<br />

17.0m/min.<br />

3. Burnback Time Knob: Enables to get desired length<br />

of electrode wire, which protrudes from the contact<br />

tip of the welding gun after welding finishing in a<br />

8