Magster-280 4x4,-330 4x4 - Lincoln Electric - documentations

Magster-280 4x4,-330 4x4 - Lincoln Electric - documentations

Magster-280 4x4,-330 4x4 - Lincoln Electric - documentations

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

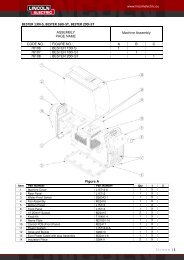

3. Drive Roll Ø 30mm: Depend on he electrode wire<br />

type and its diameter you should use rolls with<br />

proper shape and groove size (see section<br />

“Accessories”).<br />

4. Roll Presure Arm<br />

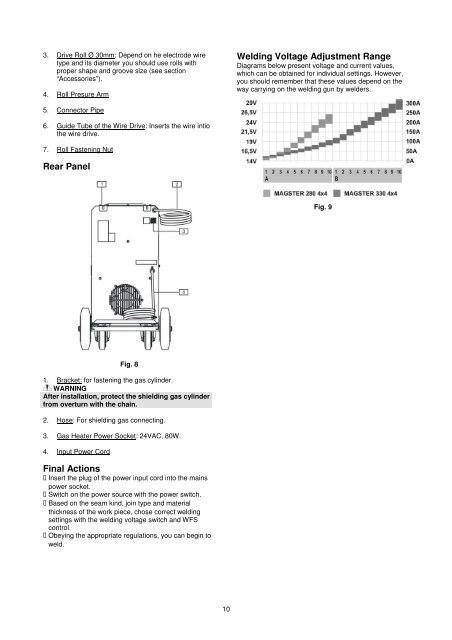

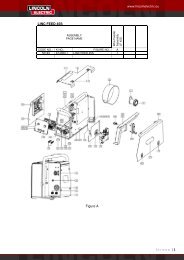

Welding Voltage Adjustment Range<br />

Diagrams below present voltage and current values,<br />

which can be obtained for individual settings. However,<br />

you should remember that these values depend on the<br />

way carrying on the welding gun by welders.<br />

5. Connector Pipe<br />

6. Guide Tube of the Wire Drive: Inserts the wire intio<br />

thewiredrive.<br />

7. Roll Fastening Nut<br />

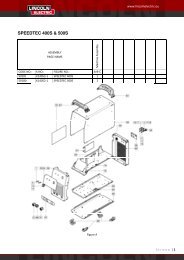

Rear Panel<br />

Fig. 9<br />

Fig. 8<br />

1. Bracket: for fastening the gas cylinder.<br />

WARNING<br />

After installation, protect the shielding gas cylinder<br />

from overturn with the chain.<br />

2. Hose: For shielding gas connecting.<br />

3. Gas Heater Power Socket: 24VAC, 80W.<br />

4. Input Power Cord<br />

Final Actions<br />

Insert the plug of the power input cord into the mains<br />

power socket.<br />

Switch on the power source with the power switch.<br />

Based on the seam kind, join type and material<br />

thickness of the work piece, chose correct welding<br />

settings with the welding voltage switch and WFS<br />

control.<br />

Obeying the appropriate regulations, you can begin to<br />

weld.<br />

10