Plastizität und Bruchmechanik - Technische Fakultät

Plastizität und Bruchmechanik - Technische Fakultät

Plastizität und Bruchmechanik - Technische Fakultät

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

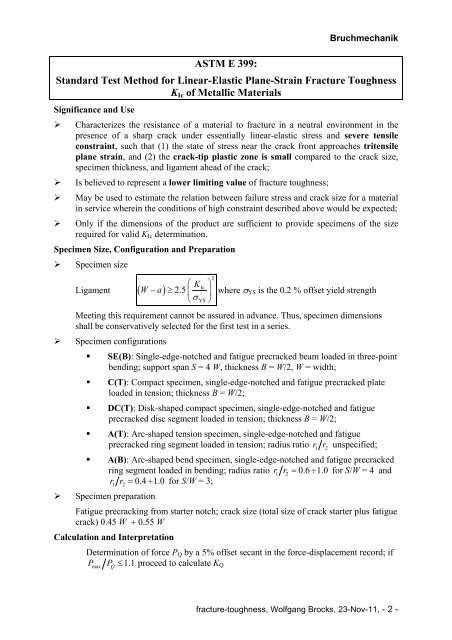

ASTM E 399:<br />

<strong>Bruchmechanik</strong><br />

Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness<br />

K Ic of Metallic Materials<br />

Significance and Use<br />

‣ Characterizes the resistance of a material to fracture in a neutral environment in the<br />

presence of a sharp crack <strong>und</strong>er essentially linear-elastic stress and severe tensile<br />

constraint, such that (1) the state of stress near the crack front approaches tritensile<br />

plane strain, and (2) the crack-tip plastic zone is small compared to the crack size,<br />

specimen thickness, and ligament ahead of the crack;<br />

‣ Is believed to represent a lower limiting value of fracture toughness;<br />

‣ May be used to estimate the relation between failure stress and crack size for a material<br />

in service wherein the conditions of high constraint described above would be expected;<br />

‣ Only if the dimensions of the product are sufficient to provide specimens of the size<br />

required for valid K Ic determination.<br />

Specimen Size, Configuration and Preparation<br />

‣ Specimen size<br />

Ligament ( W a)<br />

2<br />

⎛<br />

Ic<br />

2.5 K ⎞<br />

− ≥ ⎜ ⎟<br />

σ<br />

YS<br />

⎝<br />

⎠<br />

where σ YS is the 0.2 % offset yield strength<br />

Meeting this requirement cannot be assured in advance. Thus, specimen dimensions<br />

shall be conservatively selected for the first test in a series.<br />

‣ Specimen configurations<br />

• SE(B): Single-edge-notched and fatigue precracked beam loaded in three-point<br />

bending; support span S = 4 W, thickness B = W/2, W = width;<br />

• C(T): Compact specimen, single-edge-notched and fatigue precracked plate<br />

loaded in tension; thickness B = W/2;<br />

• DC(T): Disk-shaped compact specimen, single-edge-notched and fatigue<br />

precracked disc segment loaded in tension; thickness B = W/2;<br />

• A(T): Arc-shaped tension specimen, single-edge-notched and fatigue<br />

precracked ring segment loaded in tension; radius ratio r 1<br />

r 2<br />

unspecified;<br />

• A(B): Arc-shaped bend specimen, single-edge-notched and fatigue precracked<br />

ring segment loaded in bending; radius ratio r 1<br />

r 2<br />

= 0.6 ÷ 1.0 for S/W = 4 and<br />

r1 r<br />

2<br />

= 0.4 ÷ 1.0 for S/W = 3;<br />

‣ Specimen preparation<br />

Fatigue precracking from starter notch; crack size (total size of crack starter plus fatigue<br />

crack) 0.45 W ÷ 0.55 W<br />

Calculation and Interpretation<br />

Determination of force P Q by a 5% offset secant in the force-displacement record; if<br />

P P ≤ proceed to calculate K Q<br />

max Q<br />

1.1<br />

fracture-toughness, Wolfgang Brocks, 23-Nov-11, - 2 -